Top Flite TOPA0130 User Manual

Page 37

❏

4. Apply medium CA to the ply Saddle only,

then align the sheeting strip flush with the inside

edge of the ply Saddle and glue it in place.

Repeat this operation for the other side.

❏

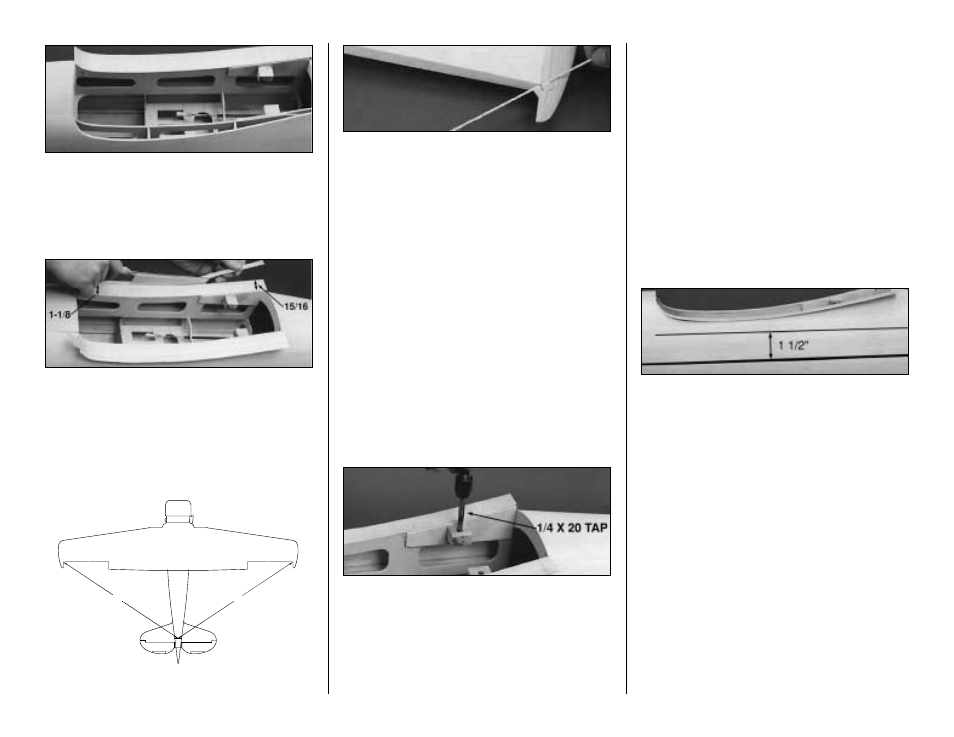

5. Measure and mark 1-1/8 " from the inside

edge of the ply Saddle 1-1/4" aft of the dowel

Former. Measure and mark 15/16" from the

inside edge of the ply Saddle at F-5B. Connect

these two marks with a strip of masking tape.

Trim and sand the sheeting to this line.

❏

6. Install the wing and check the fit. Make

adjustments as necessary. Hold a string (with

one end attached to a pin centered at the tail)

up to a wing tip. Put a piece of tape on the string

to mark the intersection of the string and the

wing tip. Swing the string over to the other wing

tip and check to see if the distances are the

same (see diagram). Adjust the position of the

trailing edge of the wing until the wing is

properly aligned.

NOTE: Make sure the wing is held

securely and cannot shift while you

are drilling the mounting holes.

❏

7. With the wing aligned and taped in place,

lightly mark the center of the wing mount holes

on the mount blocks with a 1/4" drill.

❏

8. Remove the wing and finish drilling the

holes with a #10 (or 13/64") drill bit through the

wing mount blocks. Tap the holes with a 1/4"-20

tap. Add a couple drops of thin CA to the holes

to harden the threads, then re-tap the holes

after the CA has fully hardened.

BUILD THE WING FILLET

NOTE: There are many techniques

to build a wing fillet. Some modelers

prefer to carve the entire fillet from

balsa. Others use a mixture of epoxy

and micro balloons to finish the fillet.

If you have a favorite technique, feel

free to use it. The technique

described below works fine for

MonoKote-covered aircraft.

❏

1. Draw (or tape) a reference line along the

upper & lower Fuse joint. Measure 1-1/2"

towards the Saddle, then draw a line parallel to

the reference line.

❏

2. Cover the center section of the wing with

waxed paper or plastic wrap, then bolt the wing

in position.

❏

3. Press the 1/16" balsa saddle sheeting into

contact with the wing, then run a bead of thick

CA along the seam between the balsa saddle

and the balsa saddle sheeting. This technique

will take care of any unevenness on the wing's

surface. The wing may be removed after the CA

has cured.

A

A=A

A

37