Top Flite TOPA0130 User Manual

Page 41

FIT THE FLAPS

DO THESE STEPS FOR OPERATING FLAPS

❏ ❏

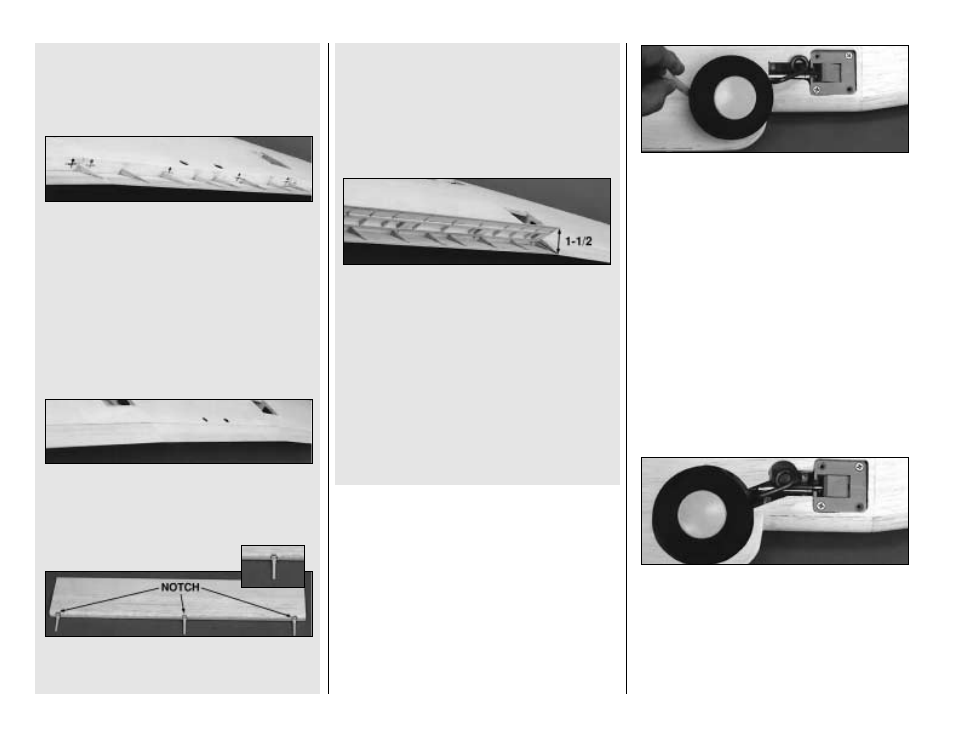

1. Mark the locations of the hinges on the

wing and flaps

(You should have already done

this step, but if not, check the wing plans for the

locations).

❏ ❏

2. Use a T-bar to true up the aft edge of

the wing sheeting in the flap section.

❏ ❏

3. Sand a radius from the LE of each

Flap around to the sheeted side (See the cross-

section on the wing plan for the required radius).

❏ ❏

4. Test fit the flaps. Check that all edges

are flush. NOTE: The aft edge of the flaps

should match the aft edge of the wing. Also

the flaps should lie flat against the trailing

edge of the wing.

❏ ❏

5. When a good fit is obtained, install the

Pivot Point Hinges (GPMQ4003). NOTE: The

hinges are not glued in until after the finish has

been applied. Drill 1/8" holes at the hinge

locations. Use a sharp #11 knife to cut a notch

in the leading edge of the flaps at the hinge

locations. This will allow the hinge to pivot in the

center of the flap's LE radius (refer to the

cross-sections on the wing plan).

❏ ❏

6. Plug the flaps with the hinges into the

wing. Check the fit and run the flaps through

their complete range of motion. The TE of the

flaps should swing 1-1/2" away from the TE of

the wing. Make any required adjustments until

the flaps swing freely. Remember, the flaps must

close flush against the wing TE.

❏ ❏

7. Insert the wire joiners into the brass

tubes and test the operation. Once again,

m a ke a d j u s t m e n t s a s n e e d e d t o a s s u r e

smooth operation.

FINAL FIT THE RETRACTS

DO THESE STEPS FOR OPERATIONAL

LANDING GEAR.

❏ ❏

1. Temporarily install the retract mechanism.

❏ ❏

2. Install the wire landing gear strut and

wheel. Carefully swing the strut down to contact

the wing. Draw a line around the wheel to mark

the area of sheeting to be removed.

❏ ❏

3. Cut away the sheeting from the inside

of the circle, leaving yourself room to make

adjustments with a drum sander.

❏ ❏

4. Cut away as much of the wing rib as

necessary, being careful not to remove more

than required.

❏ ❏

5. Fit the wheel in position. There should

be about 1/8" clearance around the wheel.

❏

6. Repeat steps 1 - 5 for the other side.

41