S o dis rate, Dat both, 854 sprayer control – TeeJet 854 Sprayer Control User Manual

Page 11: Display.stabilization, Data.display.screen.options, Calibrate.tip.level.percent

www.teejet.com

6

854 Sprayer Control

Display.Stabilization

Display Stabilization establishes the stabilization

rate that steadies the Application Rate displayed

during minor adjustments of the control system.

The controller will continue to make the required

adjustments at all times. Enter the percentage of

allowable change from the target rate in this step.

For example, the system has a target rate of 20 GPA

with 5% programmed for Display Stabilization. The

display will indicate 20 GPA at any time the actual

rate is +/- 5%, or:

• Use the PLUS or MINUS keys to change

the value.

• Press and hold the AUTO/MAN key for 3

seconds to set the value to “0.0”.

• Press the AUTO/MAN key once to set the

value to the default setting of “5%”.

• Press the PROGRAM key to accept the

value and advance to the next program step.

NOTE: The Display Stabilization value is limited to

20%. A value of 0% will disable the setting.

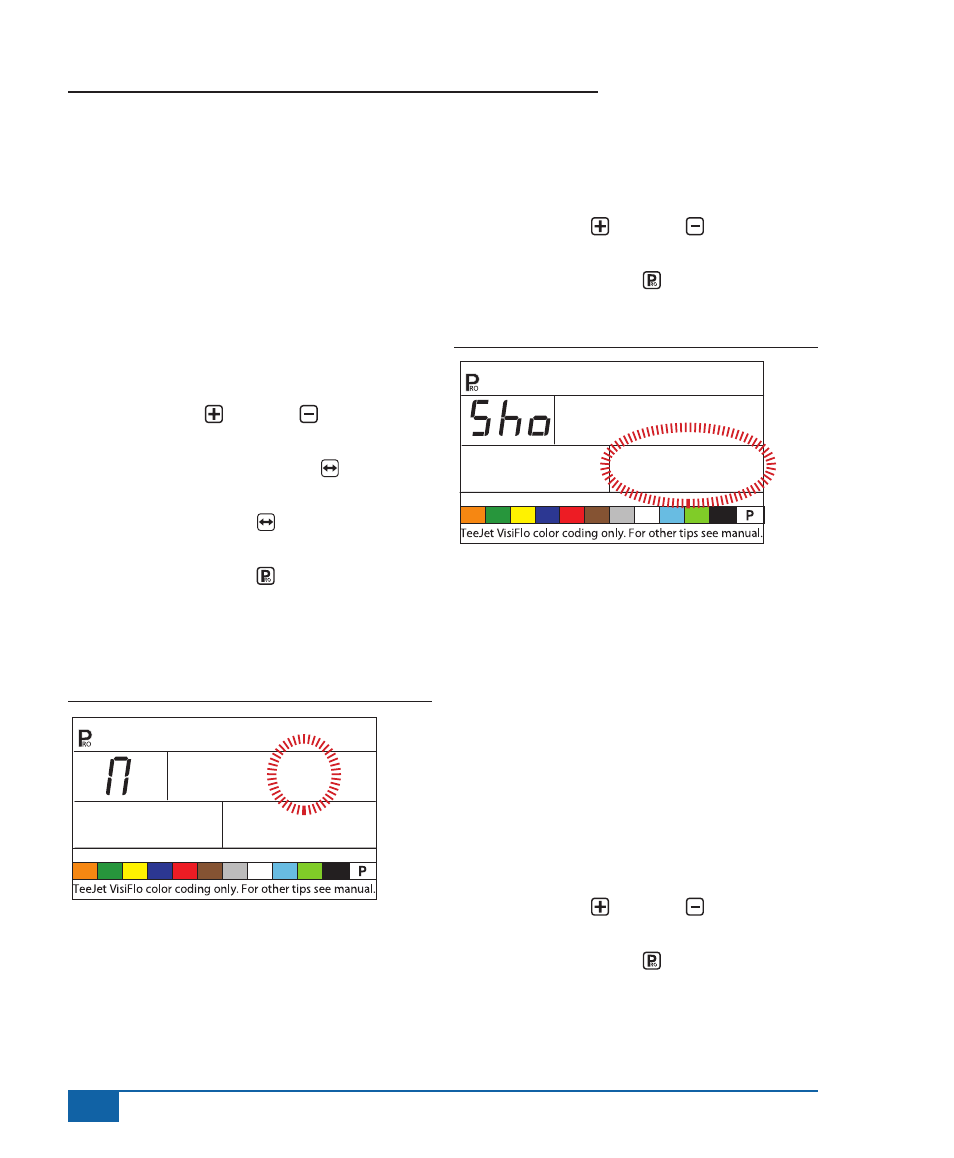

Figure 3-8: Display Stabilization

5

s O

diS

rAtE

Data.Display.Screen.Options

The lower right hand display used during normal

operations mode can be customized to display:

• volume sprayed

• area covered

• both volume sprayed and area covered

(alternating every 3 seconds)

To customize the data display options:

• Use the PLUS or MINUS keys to change

the data to be displayed.

• Press the PROGRAM key to accept the

value and advance to the next program step.

Figure 3-9: Data Display Screen

dAt

bOth

Calibrate.Tip.Level.Percent

If both a pressure sensor and a flow meter are

installed and being used, the 854 uses one sensor to

cross check the other for system errors.

Select the primary sensor (used for regulation) in

the Sensor Select step of System Setup Mode. The

opposite sensor will automatically perform the cross-

checking function.

The Calibrate Tip Level % will establish the % of

allowable error between the sensors before an

alarm is activated. All sprayer systems have some

discrepancy between pressure and flow due to

pressure drops and positioning of sensors.

• Use the PLUS or MINUS keys to change

the % of allowable error.

• Press the PROGRAM key to accept the

value and advance to the next program step.

NOTE: It is recommended that this value remain at

50% unless instructed otherwise.