0 maintenance procedures -30, 1 filters - all models, 2 belt, blower, and motor - all models – Reznor PDH Operation Manual PreevA User Manual

Page 7: 0 maintenance procedures, Side view - peh

Form O-PreevA, P/N 234661R8, Page 7

3.1 Filters - All Models

Check the filters.

Clean permanent filters, allow to dry, and re-install.

Replace dirty disposable filters. Exposure to humid makeup air can accelerate filter

degradation. Systems with disposable filters require more frequent filter inspection.

Remove dirt and grease from the motor and blower.

Check the belt for wear and tension. Adjust belt tension as needed. Adjust the belt ten-

sion by turning the adjusting screw on the motor base. Replace worn belts. (

IMPOR-

TANT: If a belt is replaced, after 8 hours of operation, recheck the tension.)

Linked Belts - If the belt needs tightening, the recommended method of tightening the

belt length is to count the number of links and remove one link for every 24. (A link is

made up of two joining sections of belt. For easier removal of links, turn the belt inside

out. But be sure to turn it back before installing. If belt is removed or replaced, be sure

to align directional arrows on the belt to the proper drive rotation.) The belt tension

should be checked after the first 24 hours of running at full load and at regular mainte-

nance inspections. Be sure that the belt is aligned in the pulleys.

Solid Belts - Adjust the belt tension by turning the adjusting screw on the motor base

until the belt can be depressed 3/4” (19mm). After correct tension is achieved, re-

tighten the locknut on the adjustment screw. Be sure that the belt is aligned in the

pulleys.

The motor supplied has lifetime lubrication and sleeve bearings. If the motor has been

replaced with one that has oil cups or grease fittings, lubricate the motor.

Check current draw to motor rating plate.

Blower bearings are permanently lubricated cartridge ball bearings and do not require

greasing.

3.2 Belt, Blower,

and Motor - All

Models

3.0 Maintenance

Procedures

PDH/SDH/RDH Sizes 75/100

125/150 175/200/225

250/300

350/400A

PEH/REH Sizes

10A/20A/

40A

15B/30B/

60B

N/A

30D/60D/

90D/120D

40E/80E/120E

PXH/RXH

000A

000B

000C

000D

000E

RHH/SHH

N/A

N/A

130/180

260

350

Filters - (Qty) Width

x Height in inches

(2)

16 x 25

(2)

20 x 25

(2) 16 x 16;

(2) 16 x 20

(3) 16 x 16;

(3) 16 x 20

(1) 16 x 16;( 2) 20 x

20; (3) 16 x 20

Dirty Filter Switch - If equipped with a dirty filter switch, check the condition of the

sensing tubes to be sure that they are not blocked. Check the wiring connections. To

set a new switch, see Installation Manual, Paragraph 7.6. Replacement switch is

P/N

105507.

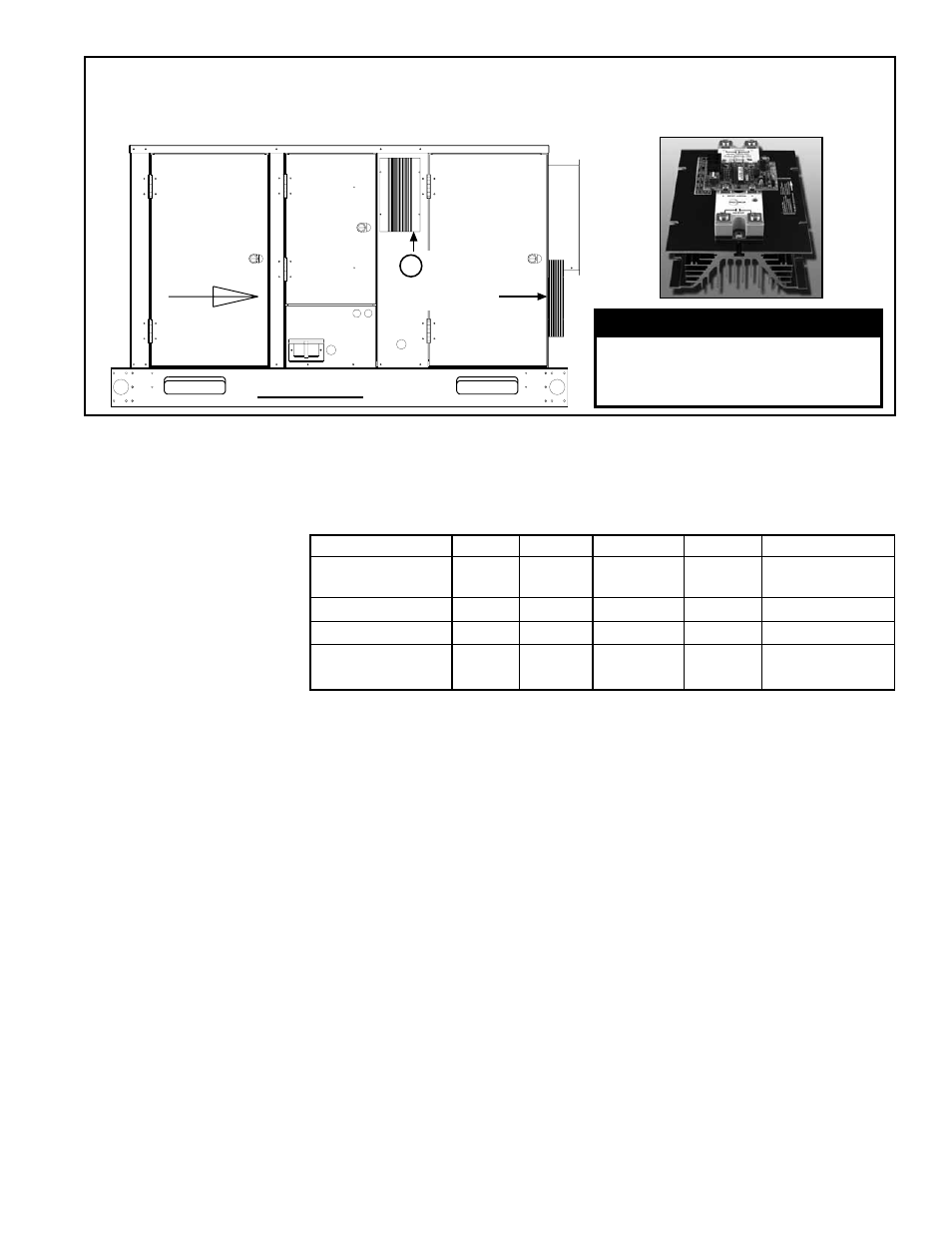

Side View - PEH

Airflow

SCR Control

and Heatsink

Locations

51

Blower

Electrical

Electric

Heat

Section

DANGER

High voltages are present on

the terminals of the SCR power

controller(s).

SCR Power Control and Heatsink

in Option D12D (one or two

required depending on amps)

FIGURE 1C - Locations of the SCR Power Controls

with Heatsinks used on Model REH and PEH units

with Modulating Heat Control Option D12D