Reznor PDH Operation Manual PreevA User Manual

Page 23

Form O-PreevA, P/N 234661R8, Page 23

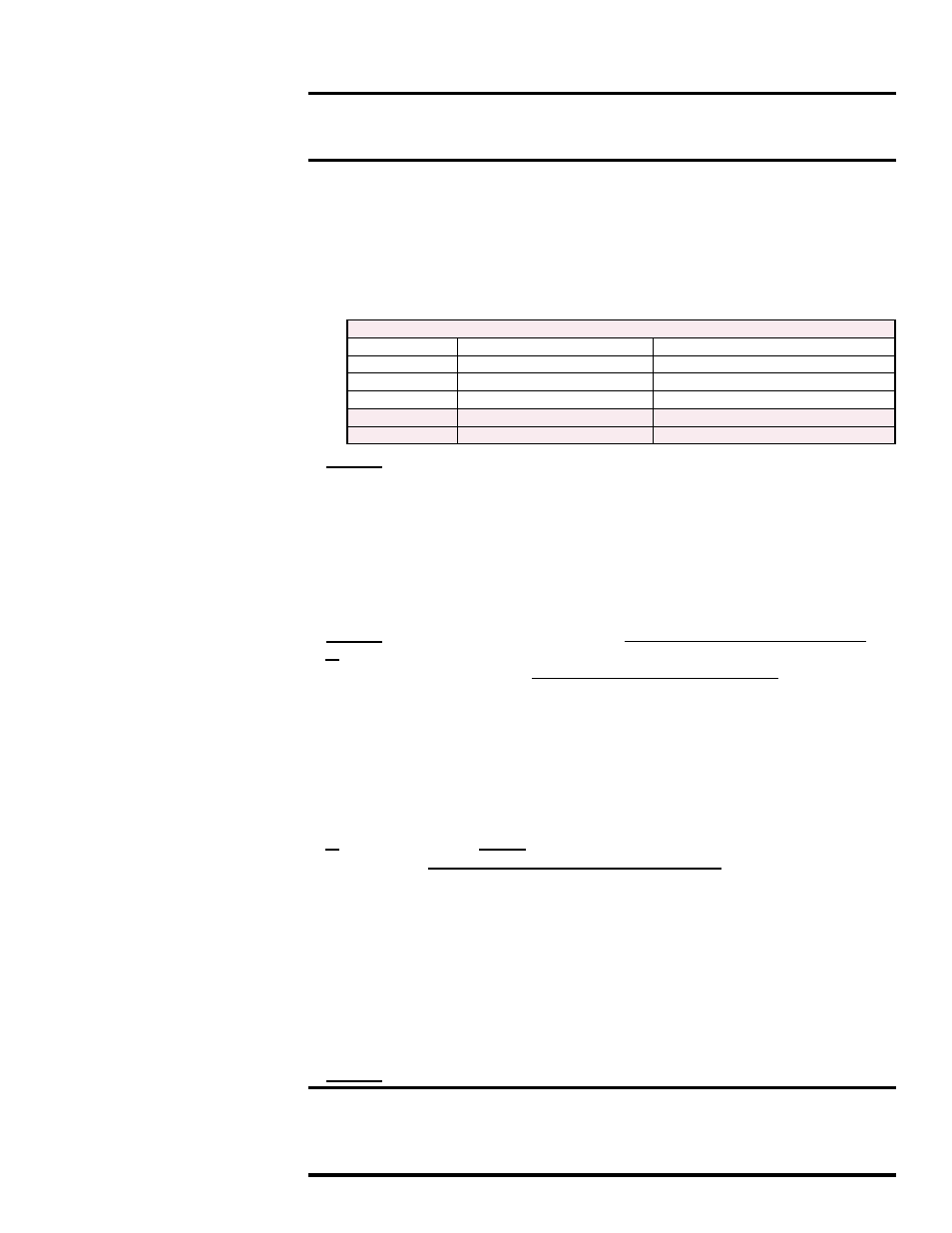

Compressor Oil Charge

PDH/SDH/RDH

75/100/25/150/175/200/225

250/300/350/400A

SHH/RHH

130/180

260/350

PXH, RXH

000A/000B/000C

000D/000E

PEH/REH

10A/20A/40A/15B/30B/60B

30D/60D/90D/120D/40E/80E/120E

Compressor

ZP29K

ZP57K

POE Oil (oz.)

21

52

□

Step 3. Mount the Replacement Compressor

Do not remove the dust cover or rubber shipping plugs until all other system con-

nections are complete (i.e. new liquid line filter drier(s) installed and all tubing

changes made - see Steps 4 and 5). The amount of time the compressor is open

to the atmosphere must be kept to a minimum.

Use the new mounting grommets and sleeves that are shipped with the compres-

sor to mount it. The sleeves will prevent over compression of the grommets. Re-

use the mounting bolts from the compressor that was removed. The mounting

bolts will bottom out when tight.

□

Step 4. Install New Filter Drier(s) (Select procedure that applies.)

IF the oil measured in Step 2 was not significantly less than the amount shown in

the table or the test for acid in

Step 2 did NOT indicate burnout , install a new

R410A refrigerant liquid line filter drier. The filter drier must be rated for no less

than 600 psig and be the proper size for the circuit. Because R410A refrigerant

requires POE oil which absorbs moisture quickly, it is important to change the filter

drier any time the circuit is opened.

It is recommended to use a tubing cutter when cutting out a filter drier as the des-

iccant absorbs and holds moisture better when it is cool. Heat from a torch may

cause moisture to leave the filter and be absorbed in the oil.

Continue to

Step 5.

IF the oil measured in Step 2 was significantly less than shown in the table or the

test for acid in

Step 2 did indicate compressor burnout, do the following:

a) Install a liquid line filter drier.

If there is acid, install an acid removing filter drier.

Size the acid-removing filter drier at least one capacity size larger than normally

required for the circuit.

b) Install a temporary filter drier in the suction line. When there is acid, a 100%

activated alumina suction filter drier is recommended. The suction line drier

should be sized properly for the circuit and have a service access fitting to

monitor pressure drop across the drier. (

NOTE: Suction line filter drier must be

removed after 72 hours of operation.)

Step 12 includes the remaining procedures required for cleanup of a burnout.

Continue to

Step 5.

□

Step 5. Braze on Suction and Discharge Lines

CAUTION: Do not leave system open to the atmosphere any longer

than minimum required for installation. POE oil in the compressors is

extremely susceptible to moisture absorption. Always keep ends of

tubing sealed during installation. See Hazard Levels, page 2.

e) To test for acid and to assure excess oil does not remain in the circuit, remove

oil from the failed compressor. Measure the amount of oil.

CAUTION: In addition to the required eye protection and gloves, care

should be taken in handling POE oil because it may cause damage to

certain plastics and roofing materials. See Hazard Levels, page 2.

If the oil taken from the compressor and measured is found to be significantly

lower than listed in the table below, clean the excess oil through use of suction

and liquid line filter driers.

Beginning in Step 4, follow the same procedure

as for burnout cleanup.

Use an acid test kit to check the oil for acid.

If acid is found, beginning in

Step 4, follow procedures indicated for burnout cleanup.

Dispose of oil and compressor using an approved environmentally safe dis-

posal method.