Dx cooling module), Troubleshooting (cont’d) – Reznor PDH Operation Manual PreevA User Manual

Page 36

Form O-PreevA, Page 36

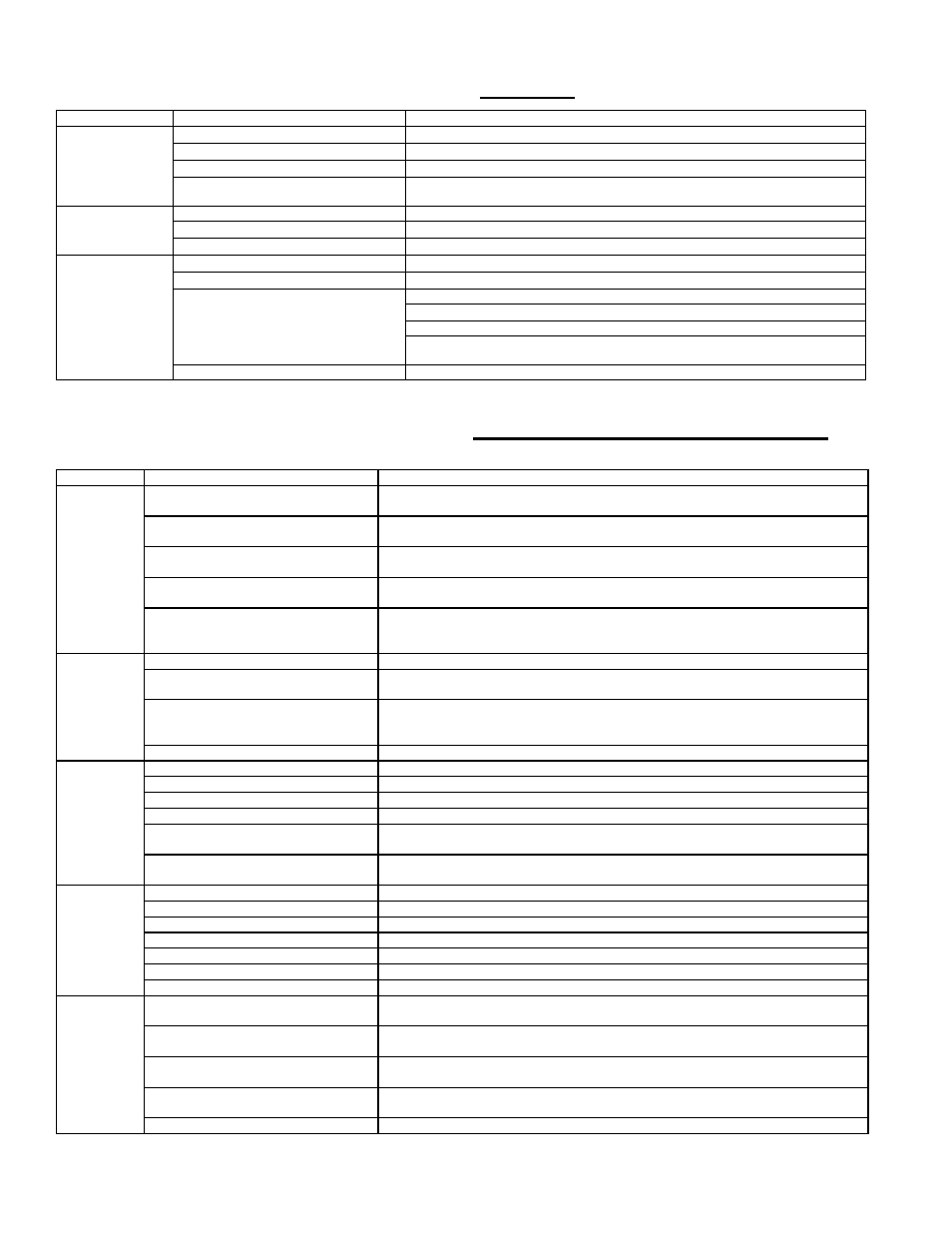

4.5 Troubleshooting - Refrigeration Circuit (All Models with a DX Cooling Module)

Consult the condensing unit literature for more specific information.

SYMPTOM

POSSIBLE CAUSE

REMEDY

A. Compressor

will not start.

1. Power off, loose electrical connections

or fuse open.

1. Check disconnect switch, fuses and wiring. Replace parts or repair as necessary

2. Compressor contactor not closing.

2. Check voltage to contactor coil, transformer, slave relay, system. Replace parts as

necessary.

3. Internal compressor thermal overload

open.

3. If compressor is hot, allow 2 hours to cool. See D. below.

4. Compressor defective.

4. Check compressor for electrical failure. Compressor may be seized; check

refrigerant. If necessary, replace compressor.

5. High or low pressure switch open or

defective.

5. If manual reset (high pressure), reset switch. (Switch opens at 600 psi and will not

reset above 400 psi.) If auto reset (low pressure) does not reset and everything else is

OK, replace low pressure switch.

B. Compressor

starts but

cuts out on

low pressure

(switch

activates at 35

psig.)

1. Low refrigerant charge.

1. Check subcooling; see condensing unit manual or Paragraph 3.7.4, Step 11.

2. Airflow restricted.

2. Check for dirty evaporator coil, dirty filters, dampers closed, iced evaporator coil,

improper belt, check motor amps, check duct design.

3. Restriction in refrigerant line.

3. Check subcooling and superheat; see condensing unit manual or Paragraph 3.7.4,

Step 11. Check operation of the thermal expansion valve. Check for pressure drop

across the filter drier.

4. Defective low pressure switch.

4. Check switch (opens 35 psi; closes 50 psi). If defective, replace switch

C.

Compressor

starts but

cuts out on

high pressure

switch.

1. Refrigerant overcharge.

1. Check subcooling; see condensing unit manual or Paragraph 3.7.4, Step 11.

2. Condenser fan motor defective.

2. Check fan motor.

3. Condenser coil inlet obstructed or dirty. 3. Check coil and inlet clearances and for possible air recirculation.

4. Air or non-condensables in system.

4. Check high side equalized pressure reading with equivalent outdoor temperature.

5. Defective high pressure switch.

5. Check switch (opens at 600 psi and will not reset above 400 psi.). If defective,

replace high pressure switch..

6. Restriction in discharge or liquid line.

6. Check subcooling and superheat; see condensing unit manual or Paragraph 3.7.4,

Step 11. Check operation of thermal expansion valves.

D.

Compressor

cuts out

on thermal

overload.

1. Low voltage.

1. Check voltage.

2. Sustained high discharge pressure.

2. Check running amperage and conditions described in I.

3. High suction and discharge pressures. 3. Check thermal expansion valve setting, check for air in system.

4. Defective compressor overload.

4. If compressor is hot, allow compressor to cool for 2 hrs. Recheck for open circuit.

5. Improper refrigerant charge.

5. Check subcooling; see condensing unit manual or Paragraph 3.7.4, Step 11.

6. Bearings or pistons too tight.

6. Check for low oil level.

7. Allow time for compressor to cool.

7. Check dome temperature of the compressor.

E. Noisy

compressor.

1. Reverse rotation.

1. Check at startup. If the suction pressure rises and the discharge pressure drops, shut

down the compressor. Switch the 3-phase wiring connections.

2. Refrigerant overcharge.

2. Check pressures and subcooling; see condensing unit manual or Paragraph 3.7.4,

Step 11.

3. Liquid floodback.

3. Check thermal expansion valve setting. Check subcooling for refrigerant overcharge;

see condensing unit manual or Paragraph 3.7.4, Step 11.

3. Tubing rattle.

3. Dampen tubing vibration by taping or clamping. Carefully bend tubing away from

contact where possible.

4. Compressor defective.

4. Check internal parts. Replace defective parts or compressor.

4. Troubleshooting (cont’d)

PROBLEM

PROBABLE CAUSE

REMEDY

Unit does not

operate

1. No power to unit

1. Turn on power; check supply fuses or main circuit breaker.

2. Blown fuses

2. Check and replace if necessary.

3. Defective or incorrect wiring.

3. Check wiring and connections. Refer to wiring diagram provided with unit.

4. Defective or burned out control

transformer

4. Check secondary voltage with voltmeter. Replace if necessary.

Fan operates but

element does not

heat

1. Dirty filters

1. Check filters and clean or replace if necessary.

2. Defective air proving switch

2. Check and replace if necessary.

3. Blown element fuses

3. Check and replace element fuses if necessary.

Insufficient heat

1. Burned out element

1. Turn off power and check element resistance with ohmmeter. Replace if open.

2. Blown fuses

2. Check and replace if necessary.

3. Cycling on limit control

3.

a) Check air throughput (temperature rise).

b) Check motor rpm against nameplate rating. Replace motor if speed is too slow.

c) Defective limit control. Check wiring and connections. Check continuity through

control and replace if necessary.

4. Defective or incorrect wiring.

4. Check wiring and connections. Refer to wiring diagram provided with unit.

4.4 Troubleshooting - Electric Heat Section (PEH, REH)