0 maintenance procedures (cont’d), 7 optional cooling coil module (cont’d), 4 optional reheat module (cont’d) – Reznor PDH Operation Manual PreevA User Manual

Page 22

Form O-PreevA, Page 22

3.7 Optional

Cooling Coil

Module (cont’d)

The following instructions include major points of consideration that will ensure proper

installation and protect you from potential personal injury. Please use the following 13

Steps as a checklist, taking each item in order before proceeding to the next. If more

information is required, call the Reznor

®

Service Department.

Step 2. Determine Cause of Initial Failure and Remove the Compressor

In order to prevent a second failure, the cause of the original failure must be deter-

mined. Identify the cause and make the necessary repairs.

CAUTION: DO NOT LIFT compressor by copper tubing; damage will

occur. Compressor must remain upright.

DANGER

To avoid electrical shock, power to the compressor MUST

REMAIN OFF during performance of Steps 1 through 9

below. LOCK DISCONNECT SWITCH OFF (open).

Step 1. Verify Proper Application

Verify that the replacement compressor is identical to the model being replaced. All

system components are matched to the compressor. Replacing a compressor with

a model other than the Thomas and Betts specified replacement for these Reznor

®

PREEVA

®

units will void the product warranty. See part numbers for R410A reheat

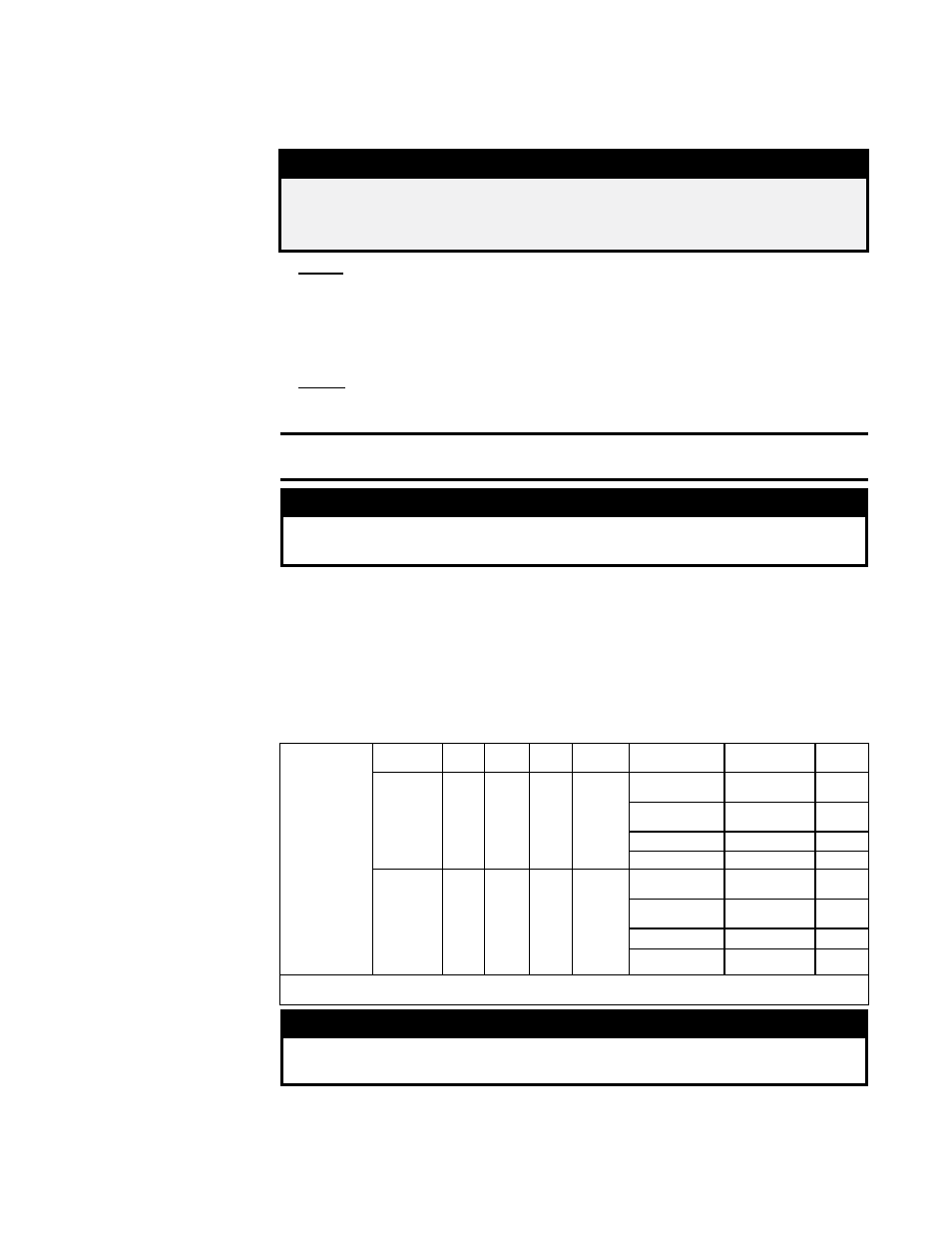

pump compressors listed in the table below.

3.7.4 Optional Reheat

Module (cont’d)

3.0 Maintenance

Procedures

(cont’d)

Replacement

Scroll

Compressors

for Reheat

Module

(R410A

Refrigerant)

IMPORTANT:

The Model

of the

replacement

compressor

MUST BE

IDENTICAL

to removed

compressor.

SDH, PDH,

RDH

SHH,

RHH

PEH,

REH

PXH,

RXH

ARI

Tonnage

Voltage

Compressor

Model*

Reznor

®

P/N

75, 100,

125, 150,

175, 200,

225

130,

180

10A,

20A,

40A,

15B,

30B,

60B

000A,

000B,

000C

2.4

208-240/1/60

(AK2 and AK3) ZP29K5E-PFV 216673

208-240/3/60

(AK5 and AK6) ZP29K5E-TF5 216674

460/3/60 (AK7) ZP29K5E-TFD

216675

575/3/60 (AK8) ZP29K5E-TFE

234055

250, 300,

350, 400A

260,

350

30D,

60D,

90D,

120D,

40E,

80E,

120E

000D,

000E

4.8

208-240/1/60

(AK2 and AK3) ZP57K3E-PFV 216685

208-240/3/60

(AK5 and AK6) ZP57K3E-TF5 216686

460/3/60 (AK7) ZP57K3E-TFD

216687

575/3/60 (AK8) ZP57K3E-TFE

216688

*Model No. of replacement R410A scroll compressor must be identical to the one removed including the

“E”

(ZP29Kx

E-xxx) which indicates POE compressor oil.

Use a high temperature torch to disconnect the suction line and the discharge line

from the compressor.

d) Remove the mounting bolts and the compressor. Save the mounting hardware

to attach the grommets and sleeves shipped with the replacement compressor.

Refrigerant System Maintenance

a) BEFORE REMOVING THE FAULTY COMPRESSOR, remove refrigerant charge

using proper recovery procedures. Call 1-800-441-9450 for the name of the near-

est Dupont authorized distributor or 1-800-ASK-KLEA (IGI) for information on their

refrigerant reclaim programs.

b) Disconnect wires. All compressor wiring is connected using a black molded

plastic plug. Remove the plug from the compressor.

c) Open access ports so that pressure does not build up in the system. Before

unbrazing stubs from the compressor, cut suction and discharge tubing with a

tubing cutter.

WARNING

Wear eye protection and gloves when handling refrigerant or oil

and when brazing.

WARNING

Have a fire extinguisher near. The compressor contains oil. There

is a risk of fire when unbrazing stubs.