0 maintenance procedures (cont’d) – Reznor PDH Operation Manual PreevA User Manual

Page 16

Form O-PreevA, Page 16

3.4 Gas-Fired Heat

Section - PDH,

SDH, RDH, RHH,

& SHH (cont’d)

3.4.5 Gas Train

Components (cont’d)

Manifold Pressures for Option AG58 or D12G Gas Modulation System

(cont’d)

To adjust AG58 or D12G gas modulation ball valve on Model SHH, RHH, or RDH (Sizes 175-400),

follow instructions below:

1. Checking modulation requires a 0-10 DC volt generator and a manometer capable of reading to 0.10" w.c. .

a) Connect the manometer to the manifold pressure tap next to the transducer (

FIGURE 4, page 14).

b) Connect the leads from the 0-10 DC volt generator to the “analog + and _” screw terminals on the control board

after marking, removing, and capping the wires already at those terminals.

c) Initiate a call for heat with either the thermostat (Option CL36, modulating wall heating/cooling Model T7350M)

if equipped with Option AG58 or the FX06 controller (refer to Form CP-PREEVA-D12B/D/E/F/G) if equipped

with Option D12G.

2.

Run the unit at 100% by setting the DC voltage at 10 volts; measure the manifold pressure. If the manifold

pressure matches the High Setting value in the chart (above), continue to Step No. 3. If the manifold pressure

does not match the value in the chart and the ball valve is fully or close to fully open, adjust the pressure screw(s)

on the Honeywell valve (See

FIGURE 5 and the CAUTION on page 15) until the pressure matches the chart.

When the manifold pressure measured at the manometer matches the pressure listed in the chart, make a note

for future reference of the position of the ball valve stem in relation to the dash marks on the actuator.

3.

Reduce the DC volts to 2 volts and allow the ball valve to go to its lowest setting. Check the manifold pressure

on the manometer. If the manifold pressure matches the Low Setting value in the chart, skip to Step No. 4. If the

manifold pressure does not match the low (0%) value on the chart, the ball valve will need to be adjusted. Follow

these steps:

a) While the unit is still firing at 0% modulation, remove the ball valve actuator. To do this, locate the screw on

the rear of the actuator and remove it. Loosen the actuator set screw (See

FIGURE 6, page 15), and carefully

remove the actuator by lifting it straight up. Do not disconnect any wires.

b) Using adjustable pliers, slowly turn the ball valve stem until the manifold pressure on the manometer matches

the low setting on the chart.

Important NOTE: If the valve is adjusted too far closed and the flame goes out, let the unit recycle and then

manually open the ball valve to the 100% open position noted in Step No. 2. When the unit is firing at full fire,

re-attach the actuator to the ball valve, and repeat the procedure beginning with Step No. 2.

c) When the manometer readings match the values in the chart and before re-installing the actuator, the burr left

on the ball valve stem from the previous set screw setting needs to be removed. Either lightly file the burr on

the valve stem to prevent the set screw from returning to the previous position or remove the valve stem, rotate

it 180° so that the set screw contacts the opposite side of the stem, and re-install the valve stem.

d) Re-install the actuator making sure it is level on the ball valve mounting plate.

e) Re-check the setting by going to full fire (Set DC volts to 10 volts) and then returning to 2 volts. Measure the

manifold pressure. The adjusted gas pressure should be close to the value on the chart. If not, repeat the

procedure.

4.

When the settings are in agreement with the chart and testing is complete, remove the manometer. Remove the

wire leads from the DC volt generator and replace the thermostat or FX06 control wiring.

3.0 Maintenance

Procedures

(cont’d)

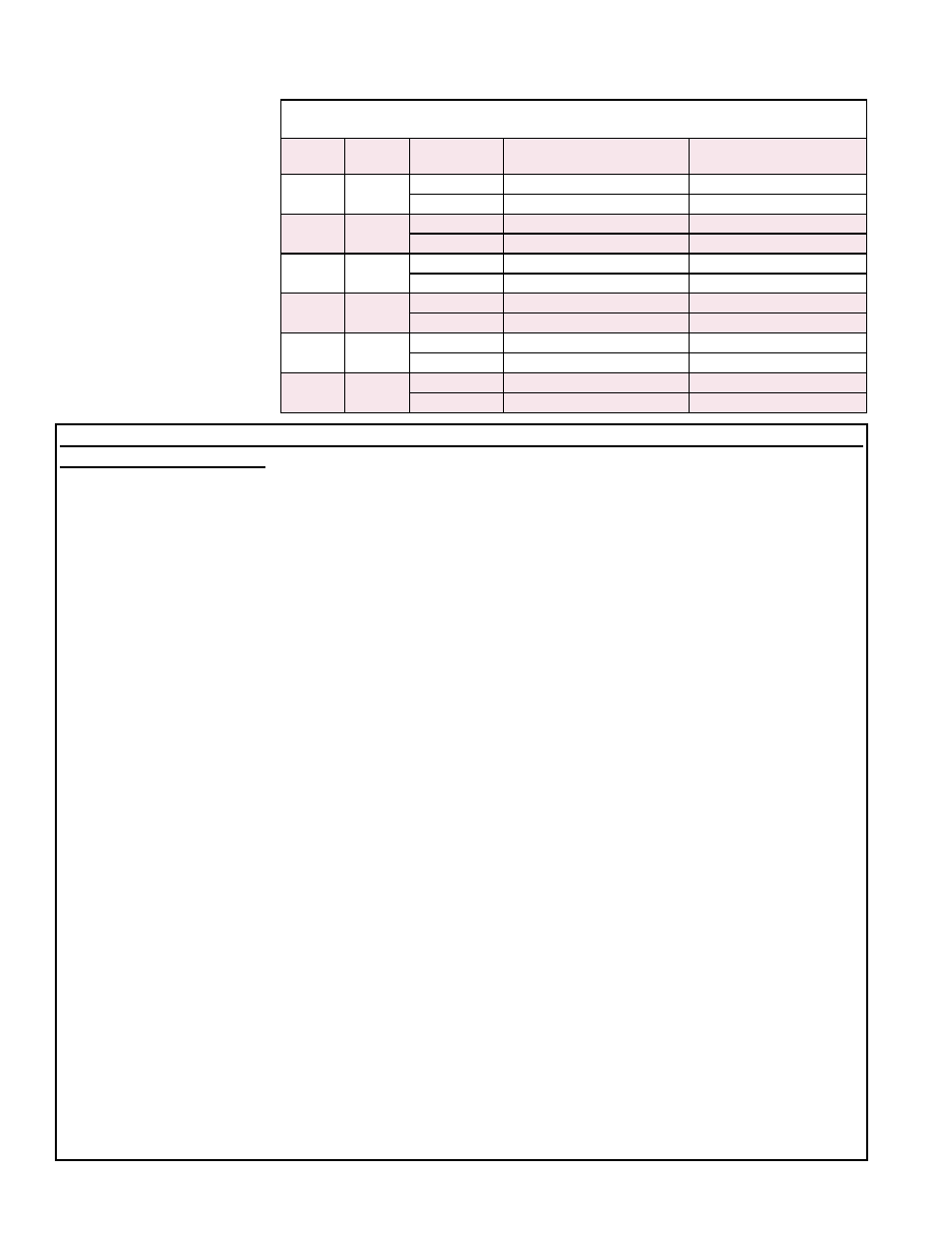

Manifold Pressure (" w.c.) Measured at the Pressure Tap by the Gas

Transducer - Gas Control Option AG58 or D12G (cont’d)

RDH

Size

RHH/

SHH

Gas

Type

High Setting

100% on ModHeat

Low Setting

0% on ModHeat

200

180

Natural

3.4

0.15

Propane

10.0

0.25

225

--

Natural

3.4

0.15

Propane

10.0

0.30

250

--

Natural

3.4

0.15

Propane

10.0

0.25

300

260

Natural

3.4

0.15

Propane

10.0

0.30

350

--

Natural

3.4

0.15

Propane

10.0

0.25

400A

350

Natural

3.4

0.15

Propane

10.0

0.25