0 maintenance procedures (cont’d), Warning, 8 optional evaporative cooling module (cont’d) – Reznor PDH Operation Manual PreevA User Manual

Page 28

Form O-PreevA, Page 28

3.0 Maintenance

Procedures

(cont’d)

WARNING

Disconnect all power to the unit before doing any maintenance.

Failure to do so can cause electrical shock, personal injury, or

death.

Pre-Filters and Media - Over time, excessive amounts of dirt or mineral deposits may

begin to build up on the pre-filters and media. Annually, wash scale and dirt from the

metal pre-filters (pre-filters are optional and may not be on your cooler) and the enter-

ing surface of the media.

Remove the pre-filters (remove the door and slide out). Clean the metal pre-filters with

soap and water and rinse thoroughly.

Clean the entering side of the media using a garden hose, mild soap, and a

soft

bristled brush. When the media becomes too clogged with mineral deposits and dirt

that it cannot be cleaned, the pads should be replaced. The average pad life expec-

tancy is approximately three cooling seasons. Order replacement media pads from

your distributor.

Media - 12" Glacier-Cor® or Glasdek®

PDH/SDH/RDH

PEH/REH

PXH/RXH RHH/SHH

(Qty) Dimensions - inches

(Qty) Dimensions - mm

75, 100

10A, 20A, 40A

000A

N/A

(2) 27-3/32 x 12; (1) 27-3/32 x 7-1/2

(2) 688 x 305; (1) 688 x 191

125, 150

15B, 30B, 60B

000B

N/A

(2) 27-3/32 x 12; (1) 27-3/32 x 5-1/2

(2) 688 x 305; (1) 688 x 140

175, 200, 225

N/A

000C

130 ,180 (2) 36 x 12; (1) 36 x 7-1/2

(2) 914 x 305; (1) 914 x 191

250, 300

30D, 60D, 90D, 120D

000D

260

(3) 36 x 12; (1) 36 x 11-3/4

(3) 914 x 305; (1) 914 x 298

350, 400A

40E, 80E, 120E

000E

350

(4) 36 x 12; (1) 36 x 7-3/4

(4) 914 x 305; (1) 914 x 197

Optional Pre-Filters for Evaporative Cooling Module - 1" or 2" Aluminum Filters

PDH/SDH/RDH

PEH/REH

PXH/RXH RHH/SHH

(Qty) Dimensions - inches

(Qty) Dimensions - mm

Top Row

Bottom Row

Top Row

Bottom Row

75, 100

10A, 20A, 40A

000A

N/A

(2) 16 x 12

(2) 16 x 16

(2) 406 x 305

(2) 406 x 406

125*, 150*

15B*, 30B*, 60B*

000B*

N/A

(1) 16 x 12;

(1) 26 x 12

(1) 16 x 16;

(1) 16 x 25

(2) 406 x 305;

(1) 660 x 305

(1) 406 x 406;

(1) 406 x 635

175, 200, 225

N/A

000C

130 ,180 (2) 16 x 12

(2) 16 x 16

(2) 406 x 305

(2) 406 x 406

250*, 300*

30D*, 60D*, 90D*, 120D*

000D

260

(3) 16 x 12

(3) 16 x 25

(3) 406 x 305

(3) 406 x 635

350*, 400A*

40E*, 80E*, 120E*

000E

350

(1) 16 x 12;

(2) 20 x 12

(1) 16 x 25;

(2) 20 x 25

(1) 406 x 305;

(2) 508 x 305

(1) 406 x 635;

(2) 508 x 635

NOTE: Glacier-Cor® and Glasdek® are trademarks of Munters Corporation.

* These sizes require a filter stop gasket in each row.

Qty and Sizes of

Evaporative Cooling

Media and Pre-Filters

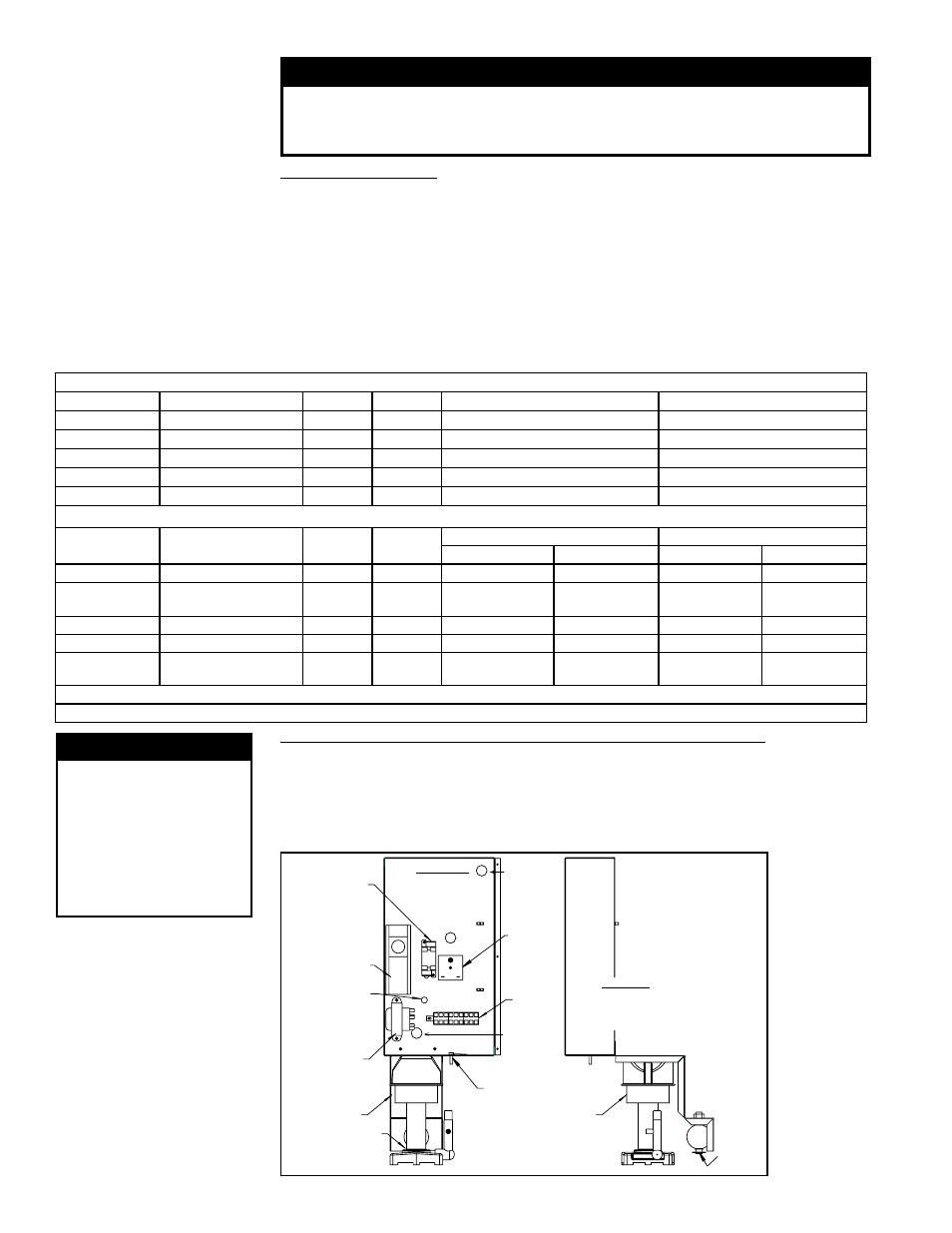

FIGURE 9 - Remove

electrical box/pump/

float switch as an

assembly. Shown here

with Option CT6, Freeze

Protection controls.

Relay Socket

and Relay

(with Option

CT6, Freeze

Protection, only)

Temperature

Controller

(with Option

CT6 only)

Temperature

Controller

Probe Port

with Option

CT6 (hole plug

without CT6)

Transformer

(208v/1or3ph

only)

Ground Screw

and Lead

Terminal

Block

Time Delay

Relay

(with Option

CT6 only)

Entrance for

power and

control wires

from unit

Front View

Electrical Box,

Float Switch,

and Pump

Assembly

Side View

Electrical Box,

Float Switch,

and Pump

Assembly

Pump

and

Motor

Float

Switch

Entrance for

pump and

switch wires

Pump and

Motor

Float

Switch

Water Pump and Inlet Basket Screen on a Float and Pump System - Annually, the

pump and inlet basket screen should be removed, disassembled, and cleaned.

3.8 Optional

Evaporative Cooling

Module (cont’d)

WARNING

Do not expose

pump motor or

any part of the

electrical box to

water. Evaporative

cooling pump is

NOT submersible.

1. Disconnect the power supply to the unit.

2. Remove the door panel. Disconnect the two-line voltage power supply wires from

the terminal block inside the electrical box. See

FIGURE 9.

3. Disconnect the water feed line hose from the upstream side of the ball valve.