Reznor PDH Operation Manual PreevA User Manual

Page 17

Form O-PreevA, P/N 234661R8, Page 17

3.4.6 Venter Motor,

Wheel, and Pressure

Sensing Tap

Remove dirt and grease from the motor casing, the venter housing, pressure sensing

tap, and the venter wheel. Venter motor bearings are permanently lubricated.

Follow these instructions for replacement of the venter motor and wheel assembly.

Keep all hardware removed to be used in re-assembling and installing the replacement

parts.

1. Turn off the gas and disconnect the electric power.

2. Open the burner/control compartment door panel.

3. Disconnect the two or three venter motor wires at the DSI control or the venter

speed control board, capacitor wires at the capacitor (if applicable), and ground

screw (located on the control panel).

4. Holding the venter motor, remove the three, four, or six screws that attach the

venter motor mounting plate to the venter housing. Remove the motor and wheel

assembly from the heater.

5. Re-assemble with the replacement venter motor and wheel assembly. See

FIGURE 7, for correct spacing. If there is a motor plate gasket, check it. If the

gasket is damaged, replace it.

Venter Motor and

Wheel Assembly

Replacement

Instructions

Gas Manifold

Transducer -

part of Gas

Control

Options AG58

or D12G

Location: See FIGURE 4, page 14 .

Function: With Option AG58 or D12G gas control, the transducer reads the manifold

pressure and sets the venter motor speed to precisely match the designed combustion

settings.

Service: If the transducer needs to be replaced, use only a factory-authorized replace-

ment part designed for the purpose.

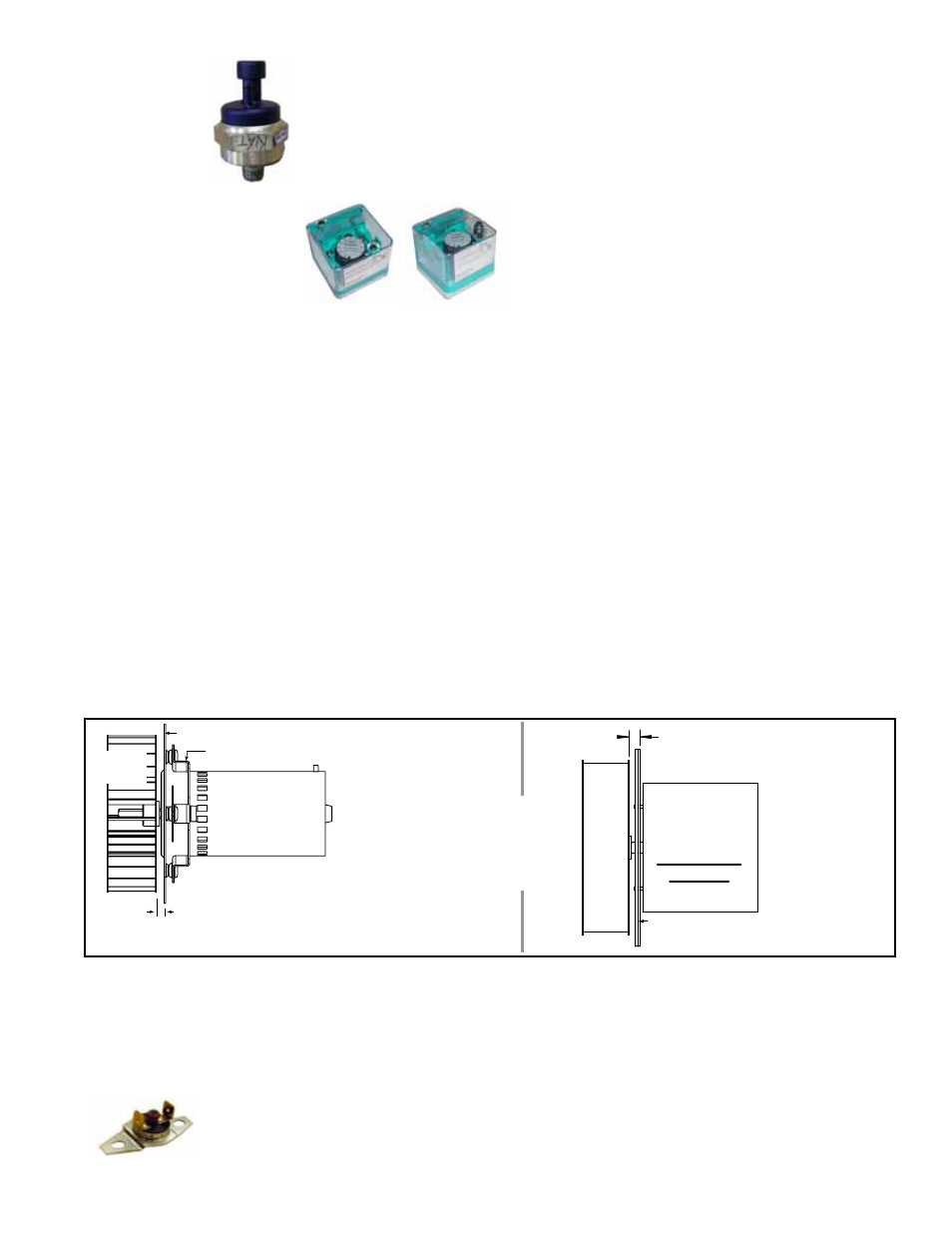

Optional Gas Pressure

Switches

Location: Low pressure switch is at the entrance to

the gas train. The high pressure switch is at the burner

end.

Function: To monitor gas pressure and shut down the

heat section if gas pressure becomes too low or too

high. The low pressure switch is an auto reset type and

is set at 50% of the maximum manifold pressure. The high pressure switch requires

manual reset and is set at 125% of manifold pressure.

Service: There are no replaceable parts and the settings are non-adjustable. If replace-

ment is required, use identical factory-authorized safety switches.

FIGURE 7 - Venter

Wheel Position on Shaft

Motor plate to wheel

5/16 (8mm) inside - PDH/SDH/RDH 75-150

7/16 (11mm) inside - PDH/SDH/RDH 175-400A

Venter Motor

Models PDH,

SDH, and RDH

Motor Plate (PDH/SDH/RDH 175-400A have a motor

plate gasket,

P/N 201472.)

Motor Mounting Plate

Venter

Wheel

NOTE: Manufacturer

recommends replacing

venter motor capacitor when

replacing venter motor.

Motor plate to wheel

RHH/SHH 130 - 5/16” (7.9mm);

RHH/SHH 180, 260, 350 - 1/2” (12.7mm)

Venter

Motor

Models RHH

and SHH

Venter Wheel

Motor Plate (and Motor

Plate Gasket, P/N 221163

6. Follow the wiring diagram to connect the venter wires.

7. Close the door panel. Restore power to the heater and turn on the gas. Light,

following the instructions on the lighting instruction plate. Check for proper

operation.

Vent Temperature Limit

Switch - RHH & SHH

Function: The vent temperature limit switch is a manual reset, temperature activated

safety control. Its purpose is to prevent the vent gas temperature from exceeding a

temperature that will harm the PVC vent pipe. Setpoint is 145°F.

Service: If the vent temperature limit switch is activated, identify and correct the cause

before resetting the switch. The switch could be activated by one or more of the fol-

lowing:

P/N 221158