Warning, 0 maintenance procedures (cont’d) – Reznor PDH Operation Manual PreevA User Manual

Page 14

Form O-PreevA, Page 14

3.4 Gas-Fired Heat

Section - PDH,

SDH, RDH, RHH,

& SHH (cont’d)

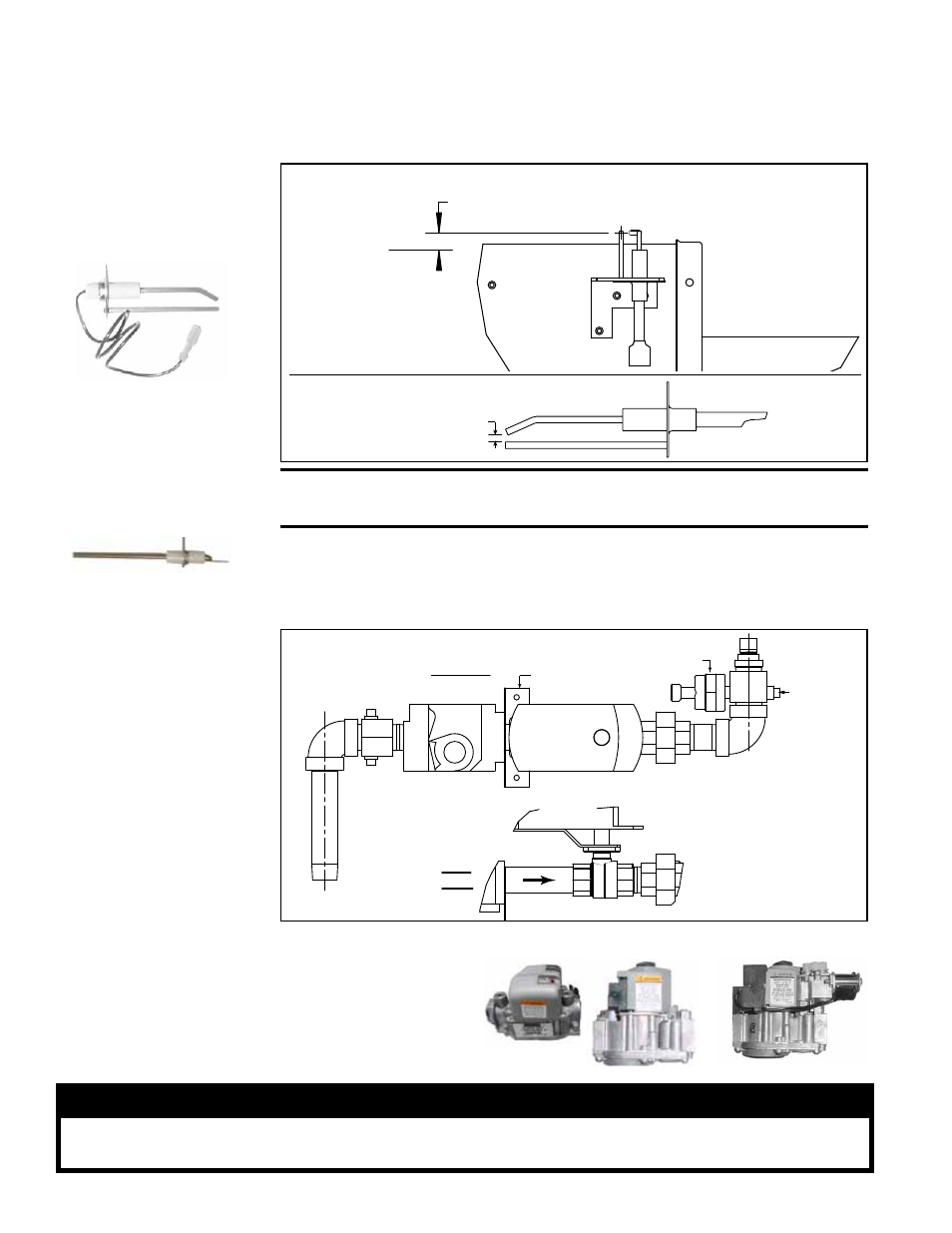

3.4.4 Ignition System

Ignitor - Locate the ignitor. Disconnect the wire; remove the screw and the ignitor.

Clean the ignitor assembly with an emery cloth.

Ignitor, P/N 209339

1/8 inch

(3.2mm)

FIGURE 3 - Ignitor Location and Spark Gap

CAUTION: Due to high voltage on the spark wire and electrode,

do not touch when energized. See Hazard Levels, page 2.

Flame Sensor,

P/N 209973

Flame Sensor - Locate the flame sensor. Disconnect the wire; remove the screw and

the flame sensor. Clean with an emery cloth.

Spark gap must be maintained to 1/8”.

IMPORTANT: When re-assembling, the brown

ground wire must remain attached to the ignitor.

Spark Gap

measurement

.436 (centerline of ignitor to top of ribbon)

Ignitor

Location

3.4.5 Gas Train

Components

Top View

Side

View

Ball Valve

Actuator

Ball Valve

Actuator

Combination

Gas Valve

Pressure

Tranducer

Ball Valve

Gas Valve

Bracket

Orifice

Manifold

Pressure

Tap

FIGURE 4 - Gas Train

Component Locations

for a Burner with 8:1

turndown (Modulating

Gas Control Option

AG58 or D12G) - applies

only to Model RDH

Sizes 175-400, Model

RHH, and Model SHH

The gas train components differ depending on the gas control option selected. See the

location of gas train components in

FIGURE 1A, page 5, and below in FIGURE 4.

Carefully remove external

dirt accumulation and check

wiring connections.

The combination gas valve

must be checked annually

to ensure that the valve is

shutting off gas flow com-

pletely.

Single-Stage Gas Valves

Two-Stage Gas Valve

WARNING

The operating valve is the prime safety shutoff. All gas supply lines must be free of

dirt or scale before connecting to the unit to ensure positive closure.

Single-Stage and

Two-Stage Gas

Valves

3.0 Maintenance

Procedures

(cont’d)