With option hw2 hot water heat module, 0 troubleshooting -37, Circuit board) - pdh, sdh, shh, rhh, and rdh – Reznor PDH Operation Manual PreevA User Manual

Page 30: 0 troubleshooting, 0 maintenance procedures (cont’d), Lights

Form O-PreevA, Page 30

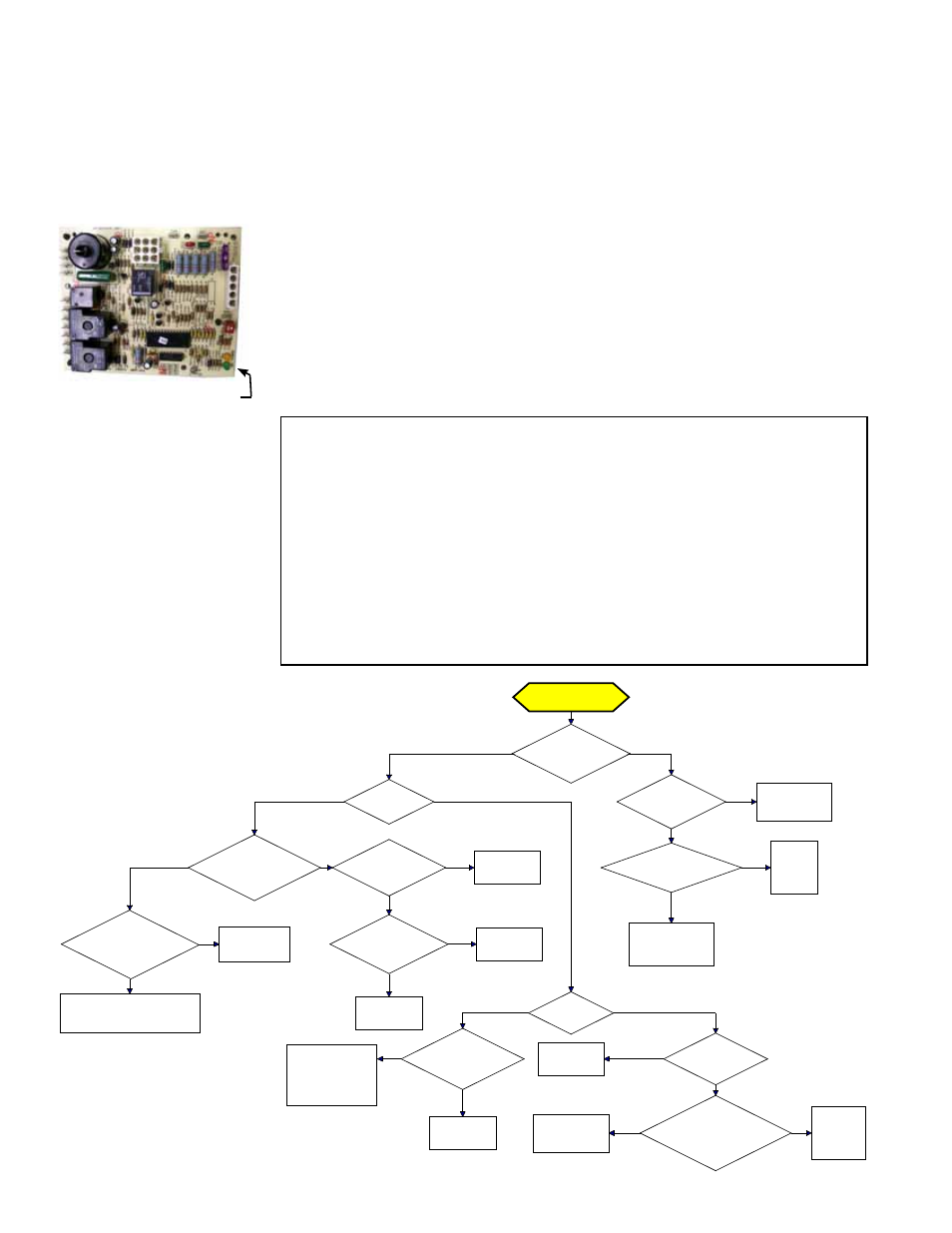

DSI Integrated Control Module (Circuit Board)

Trial Troubleshooting Flowchart - All SDH, PDH,

RDH, SHH, RHH (does not apply when

equipped with Gas Control

Option AG58 or D12G)

4.0 Troubleshooting

The integrated circuit board monitors the operation of the heater and includes two

LED signal lights that indicate normal operation and various abnormal conditions. If

the heater fails to operate properly, check this signal to determine the cause and/or to

eliminate certain causes. LED is visible through viewport on Models SDH and SHH.

Open the door panel on Models PDH and RDH.

Do not attempt to repair the DSI integrated control module; the only field replaceable

component is the fuse.

4.1 Check the Lights on the DSI Integrated Control Module

(Circuit Board) - PDH, SDH, SHH, RHH, and RDH

NOTE: Applies to all models listed and all sizes except Model RDH 175-400A Model

RHH, and Model SHH

with Gas Control Option AG58 or D12G (See Paragraph 4.2.)

IMPORTANT: When using

a multimeter to troubleshoot

the 24 volt circuit, place the

meter’s test leads into the 5

or 9 pin connectors located

on the ignition control. Do

not remove connectors or

terminals from the electrical

components. Doing so can

result in misinterpreted

readings due to the ignition

control board’s fault mode

monitoring circuits.

Control Status - Green LED Codes

Steady ON .... Normal Operation, No call for heat

Fast Flash ..... Normal Operation, Call for heat

1 Flash .......... System Lockout, Failed to detect or sustain flame

2 Flashes ...... Pressure Switch Did Not Close within 30 Seconds of Venter Motor

3 Flashes ...... High Limit Switch Open

4 Flashes ...... Pressure switch is closed before venter motor is energized

Steady OFF .. Blown Fuse, No Power, or Defective Board

Flame Status - Yellow LED Codes

Steady ON .... Flame is sensed

Slow Flash .... Weak flame (current below 1.0 microamps ±50%)

Fast Flash ..... Undesired Flame (valve open and no call for heat)

Trial for Ignition

Call for Heat

Is there a

spark across gap at

ignitor?

Does gas

ignite?

Is there minimum

flame current at the

flame sensor?

Is there

minimum flame current

at the control

module?

Replace control

module.

Check connections to flame

sensor and/or moisture in the

burner assembly.

Is the flame

sensor

corroded?

Clean flame

sensor.

Is the sensor

located in flame

correctly?

Replace flame

sesnsor.

Reposition

flame sensor.

Is gas

flowing?

Is the ignitor

position correct in the

gas flow?

Check gas pressure

and supply voltage.

If either are low,

correct and repeat

startup.

Reposition

spark ignitor.

Is there

24VAC at the gas

valve?

Is there 24VAC

from gas valve output on

control module to

chassis?

Check wiring and

connections to

gas valve.

Replace

ignition

control

module.

Replace gas

valve.

Is there

spark voltage at

control?

Check high

voltage wire

continuity.

Is there 24V P1-2

to power control?

Replace

control

module.

Check wiring

and/or 24VAC

transformer output.

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

NO

YES

YES

NO

YES

NO

YES

NO

Lights

3.0 Maintenance

Procedures

(cont’d)

3.9 Hot Water Heat - applies only to Model PXH or Model RXH

with Option HW2 Hot Water Heat Module

The closed hot water system requires a proper water treatment program with regular

water analyses, adequate regulated drains, and periodic inspection. Check for dirt or

debris that could inhibit airflow. Clean with low pressure air blower or water. Follow the

coil and control manufacturer’s instructions for maintenance and service.