5 electric heat section - models peh, reh, 0 maintenance procedures (cont’d), 7 combustion air pressure switch – Reznor PDH Operation Manual PreevA User Manual

Page 18: 8 high temperature limit control, 9 vent or vent/ combustion air system

Form O-PreevA, Page 18

3.4 Gas-Fired Heat

Section - PDH,

SDH, RDH, SHH

(cont’d)

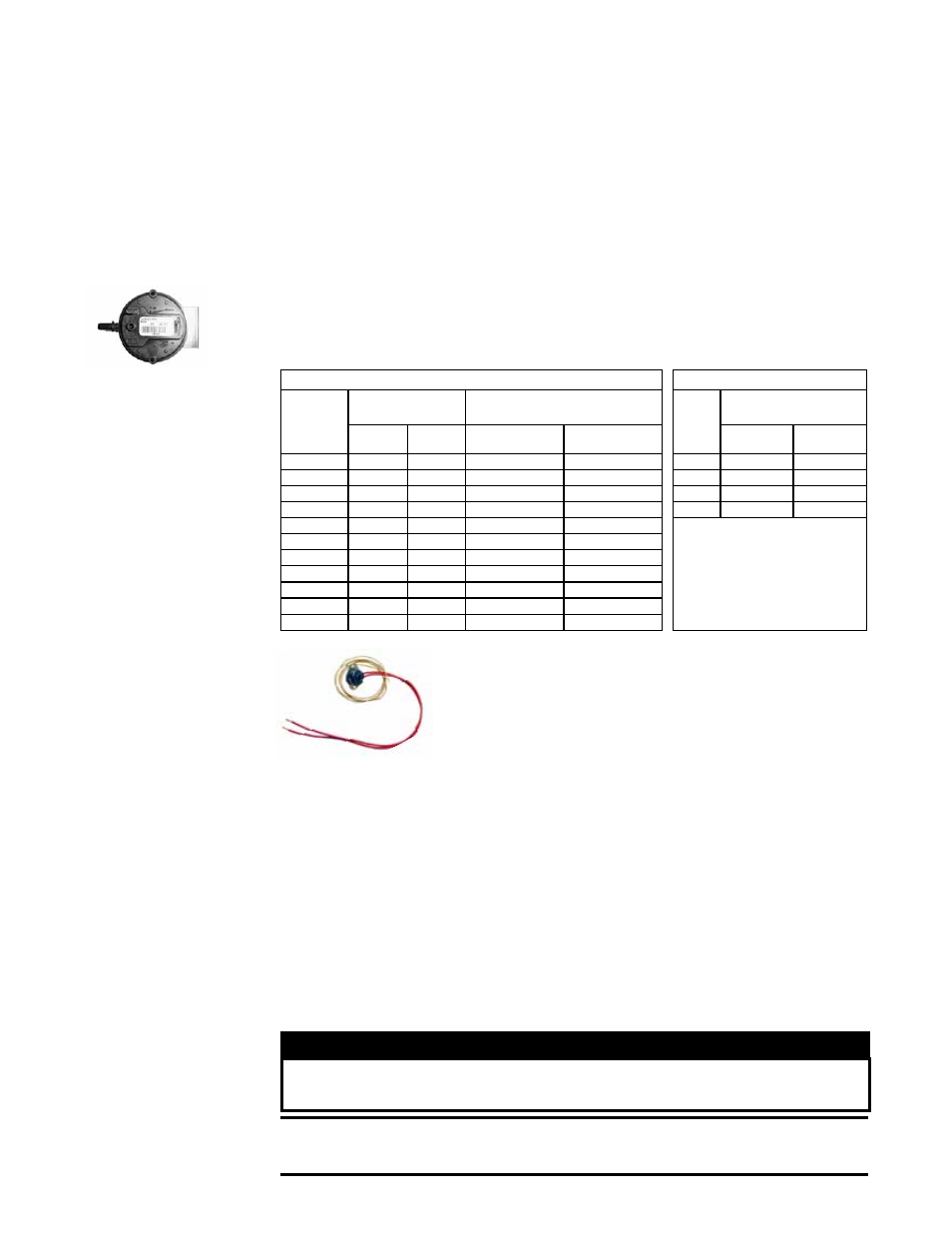

3.4.7 Combustion Air

Pressure Switch

Function: Monitors flow of combustion air.

Service: If it is determined that the pressure switch needs replacing, use only the

factory-authorized replacement part that is designed for the model and size of heater

being serviced. Two-stage units with a two-speed venter and units with electronic mod-

ulation have two pressure switches.

NOTE: A single-stage or two-stage unit operating

above 6000 ft elevation requires a high altitude high speed pressure switch.

Location: See FIGURE 1A, page 5, for location.

3.4.8 High

Temperature Limit

Control

Function: The limit control is an automatically reset, tempera-

ture activated safety control with a capillary sensor. Sensor is

extended across the heater discharge.

Service: If it is determined that the limit control needs replac-

ing, use only a factory-authorized replacement part that is

designed for the size of heater.

Location: For switch location, see FIGURE 1A, page 5.

Sizes 75-150,

P/N 210854

Sizes 175-225,

P/N 210855

Sizes 250-400,

P/N 211066

3.4.9 Vent or Vent/

Combustion Air

System

Check the complete system at least once a year. Inspection should include all joints,

seams, concentric adapter box (Model SDH), combustion air inlet opening, and the

vent terminal cap. Clean openings. Replace any defective parts. Refer to the venting

manual for requirements.

On a Model SHH, clean the vent condensate drain. After cleaning, fill the trap with

water.

3.4.6 Venter Motor, Wheel, and Pressure Sensing Tap (cont’d)

3.0 Maintenance

Procedures

(cont’d)

P/N’s & Settings - Models SDH, PDH, RDH

P/N’s & Settings - RHH & SHH

SDH, PDH,

RDH

Size

High Speed (applies

to all gas controls)

Low Speed (applies only to units with

gas controls using a 2-speed venter)

RHH/

SHH

Size

High Speed (applies to all

gas controls)

Switch

P/N

Setting

(" w.c.)

Switch P/N

Setting

(" w.c.)

Switch

P/N

Setting

(" w.c.)

75

197030

0.4

205442

0.2

130

201161

1.3

100

197030

0.4

205444

0.3

180

201161

1.3

125

196388

0.5

205444

0.3

260

201159

1.4

150

197028

0.7

205444

0.3

350

221228

2.3

175

201158

1.1

197030

0.4

200

201158

1.1

197030

0.4

225

201158

1.1

197030

0.4

250

201158

1.1

197030

0.4

300

201158

1.1

197030

0.4

350

201158

1.1

197030

0.4

400A

201158

1.1

197030

0.4

At the beginning of the cooling season or more often if needed, clean the heat section

condensate drain(s). (Models PDH, SDH, and RDH will have none or one. Model SHH

will have one or two.) Before starting the unit, fill traps with water to ensure proper

operation. If condensate drain is not needed in the winter, drain the trap before heating

season. If condensate drain is used in below freezing temperature, provide a means

of freeze protection.

3.4.10 Heat Section

Condensate Drain(s)

3.5 Electric Heat

Section - Models

PEH, REH

WARNING

Turn off the power locking the disconnect switch. Allow the

heating elements to cool.

CAUTION: Wearing eye protection is recommended when cleaning

the heating elements and cabinet.

Vent Temperature Limit Switch (cont’d) - Models RHH & SHH

•

Manifold gas pressure is too high

•

The heat content of the fuel is too high

•

Reduced circulating airflow due to dirty and/or plugged air moving components

•

Excess dirt on the heat exchangers

•

Failed heat exchanger (s)

Location: On the side of the venter housing.