Reznor PDH Operation Manual PreevA User Manual

Page 29

Form O-PreevA, P/N 234661R8, Page 29

Troubleshooting the Operation of an Evaporative Cooling Module

PROBLEM

PROBABLE CAUSE

REMEDY

Pump doesn’t run (pump &

float system) – Unit is calling

for cooling (i.e. console control

switch is in cool or summer

position) and reservoir is full.

1. Electrical connections.

1. Verify all electrical connections. Verify correct voltage at pump terminals in the

junction box. See wiring diagram.

2. Electric float switch..

2. Check position of the actuators on the electric float switch.

3. Dirty pump.

3. Clean pump.

4. Defective pump.

4. Replace pump.

Required water level (3"/76mm)

not being maintained (pump &

float control system).

1. Float valve.

1. Adjust float valve..

2. Optional drain and fill valves.

2. Check valves for proper operation.

3. Drain leaking.

3. Tighten drain fittings.

Water running off of media

pads.

1. Excessive water flow.

1. Adjust ball valve in distribution line.

2. Media pads need cleaned or replaced. 2. Clean or replace media pads.

Water not distributing evenly.

1. Distribution line clogged.

1. Flush distribution line..

2. Holes in distribution line turned.

2. Check position of distribution line. Holes should be spraying upward toward

diffuser. If not positioned with holes toward top, adjust position of distribution line.

3. Pump not running on correct voltage

(pump and float control system).

3. Check voltage at pump terminal in cooling module junction box.

Media pads becoming clogged

and discolored quickly (scale

and salt deposits).

1. Bleedoff line clogged or inadequate

bleedoff (pump and float control system).

1. Clean bleed line. A uniform buildup of minerals on the entering air face of the

media indicates insufficient bleedoff. Increase the rate until the mineral deposits

dissipate.

2. Excessive water flow.

2. Reduce flow by adjusting ball valve in distribution line..

Water blowoff from media pads

or water being pulled from

reservoir.

1. Media pads installed incorrectly.

1. Install media pads with airflow as shown on pads.

2. Water level not 3" (76mm) (pump and

float control system).

2. See second problem listed (Required water level not being maintained).

4. Remove the three sheetmetal screws holding the electrical box to the cooling

module. Remove the electrical box/pump/float switch as an assembly.

5. Remove the mesh screen from around the pump and clean any buildup of debris

and dirt. Carefully remove the base cover plate from the bottom of the pump.

Using a mild soap solution, wash all deposits from the inside of the pump and

remove all debris from the impeller.

6. Reassemble the pump. Replace the parts in exact reverse order, being careful that

everything is returned to its original position.

Water Distribution Line - Annually, the water distribution line should be flushed of

debris and contaminants.

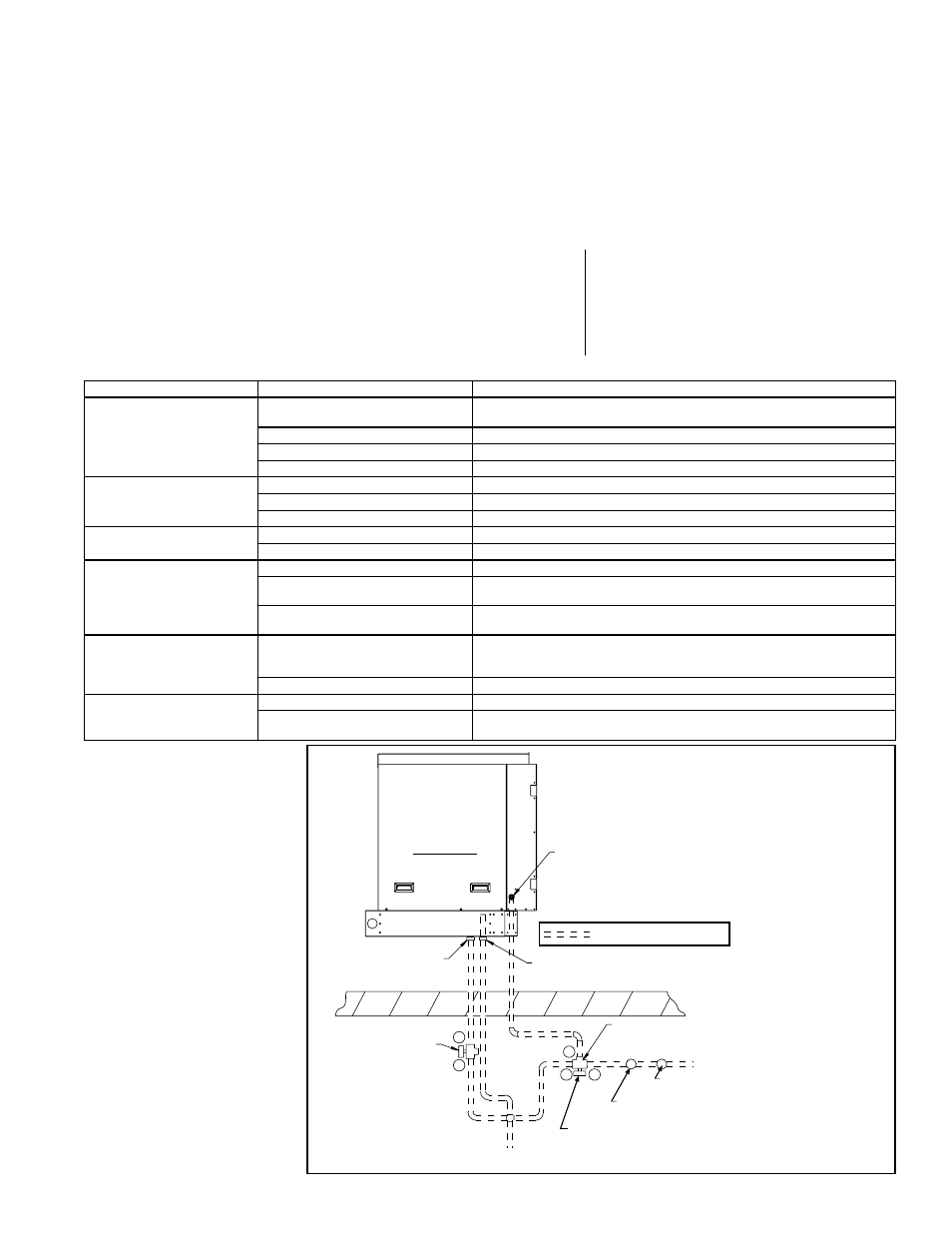

Evaporative

Cooling

Module

(factory attached)

Inlet Water Connection

(1/2 male NPT fitting)

Overflow Fitting

3/4 male NPT tapped

with 1/2 female NPT

Drain Fitting

3/4 male NPT tapped

with 1/2 female NPT

2-Way Solenoid Valve

(normally open)

1/2 female NPT

(A 2-way valve is in

Options CT1, CT2, and CT3.

Option CT6 requires

Option CT1, CT2, or CT3.)

To Drain

3-Way Solenoid Valve (valve is suitable for a maximum

close-off pressure differential of 25 psi and a system static

pressure of 300 psi) - 1/2 NPT, 2-position spring return

(normally closed at B port) (A 3-way valve is in Options CT1, CT2,

CT3, and CT5. Option CT6 requires Option CT1,CT2, or CT3.)

Actuator must be above the valve body

when mounted in horizontal piping.

Roof

Water Inlet

Field-supplied

Service Valve

Field-supplied Pressure

Regulator (if required)

A

A

B

B

C

= Field-installed Water Piping

Left Side View

FIGURE 10 - Water

Connection and Field-

Installed Fill and Drain

Valves for Pump and

Float System and

Freeze Protection Kits

1. Disconnect the power supply to the

unit.

2. Remove the access panel and the

media pads.

3. Remove the water feed line from the

downstream side of the ball valve.

4. Force a fresh water supply through the

water inlet hose to thoroughly flush the

distribution line.

5. Reassemble being careful to install media

with airflow direction as marked on the

media pads.