0 uncrating and preparation, 0 heater location (cont’d), 3 preparing for high altitude operation – Reznor LDAP Unit Installation Manual User Manual

Page 6: 1 uncrating and inspection, 5 sound data, 2 preparing for installation

Form I-LDAP, P/N 207733R6, Page 6

3.0 Uncrating and

Preparation

If the heater is being installed at an elevation above 2000 ft (610M), the input

rate will have to be derated. This is done by adjusting the outlet pressure of

the gas valve and can only be done after the heater is in operation. Follow the

instructions in Paragraph 6.1.

If the heater is being installed at an elevation above 6000 ft (1830M), the heat

section pressure switch(es) will need to be changed. If ordered with the heater

as Option DJ20, the pressure switch is shipped separately.

3.3 Preparing for

High Altitude

Operation

Pressure Switch

3.1 Uncrating and Inspection

This heater was test operated and inspected at the factory prior to crating and

was in operating condition. If the heater has incurred any damage in shipment,

document the damage with the transporting agency and contact an authorized

Reznor Distributor. If you are an authorized Distributor, follow the FOB freight

policy procedures as published Reznor, LLC.

Check the rating plate for the gas specifications and electrical characteristics of

the heater to be sure that they are compatible with the gas and electric supplies

at the installation site.

2.0 Heater Location (cont’d)

2.5 Sound

Data

Sound Chart - Model LDAP

Model

LDAP

Size

Distance

20 ft (6.1M)

25 ft (7.6M)

30 ft (9.1M)

35 ft (10.7M)

40 ft (12.2M)

db Pa µbar db Pa

µbar db Pa

µbar db Pa µbar db Pa µbar

400 69 0.058 0.580 65 0.037 0.371 62 0.026 0.258 60 0.019 0.189 57 0.015 0.145

800 72 0.080 0.800 68 0.051 0.512 65 0.036 0.356 62 0.026 0.261 60 0.020 0.200

1200 74 0.100 1.000 70 0.064 0.640 67 0.044 0.444 64 0.033 0.327 62 0.025 0.250

µbar = microbar Pa = Pascal

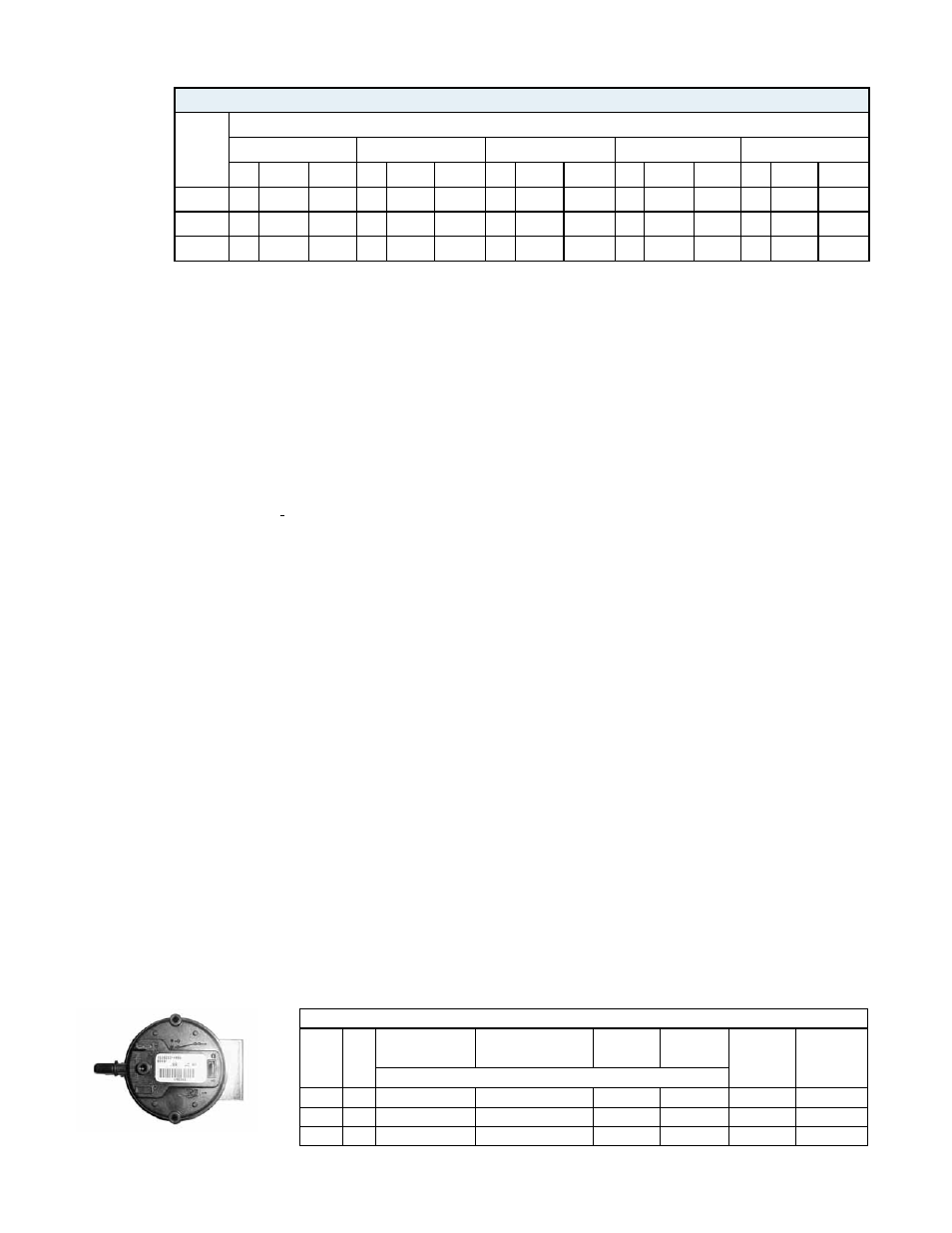

High Altitude Unit Pressure Switch(es)

Size Qty

Start-up

Cold

Equilibrium

Hot

Setpoint

OFF

Setpoint

ON

Label

Color

Switch

Part No.

Differential Pressure (in. w.c.)

400 1

1.75 to 1.45

1.00 to 0.80

0.60

0.78

Lt. Blue 197029

800 2

1.85 to 1.55

1.05 to 0.85

0.60

0.78

Lt. Blue 197029

1200 3

2.35 to 1.85

1.50 to 0.95

0.60

0.78

Lt. Blue 197029

3.2 Preparing for

Installation

IMPORTANT: The crate bottom should be removed after the heater is

lifted. Shipping brackets are attached with cabinet screws. When remov-

ing shipping brackets, re-insert ALL screws into the cabinet.

Read this booklet and become familiar with the installation requirements of

your particular heater. If you do not have knowledge of local requirements,

check with the local gas company or any other local agencies who might have

requirements concerning this installation. If the installation is above 2000 ft

(610M) elevation, follow the instructions in Paragraph 3.3 and Paragraph 6.1.

Before beginning, make preparations for necessary supplies, tools, and man-

power. Locate the hardware kit supplied with the heater. The plastic bag con-

tains spring nuts, hex nuts, “U”-shape fittings, lock washers, louvers, and com-

pression springs.

Be sure that all shipped-separate options that were ordered are at the instal-

lation site. Shipped-separate items could include a vent cap, louvers, nozzles,

hanger kit, a manual shutoff valve, a thermostat, multiple heater controls, high

temperature tape, and/or a high altitude kit.