0 mechanical (cont’d) – Reznor LDAP Unit Installation Manual User Manual

Page 12

Form I-LDAP, P/N 207733R6, Page 12

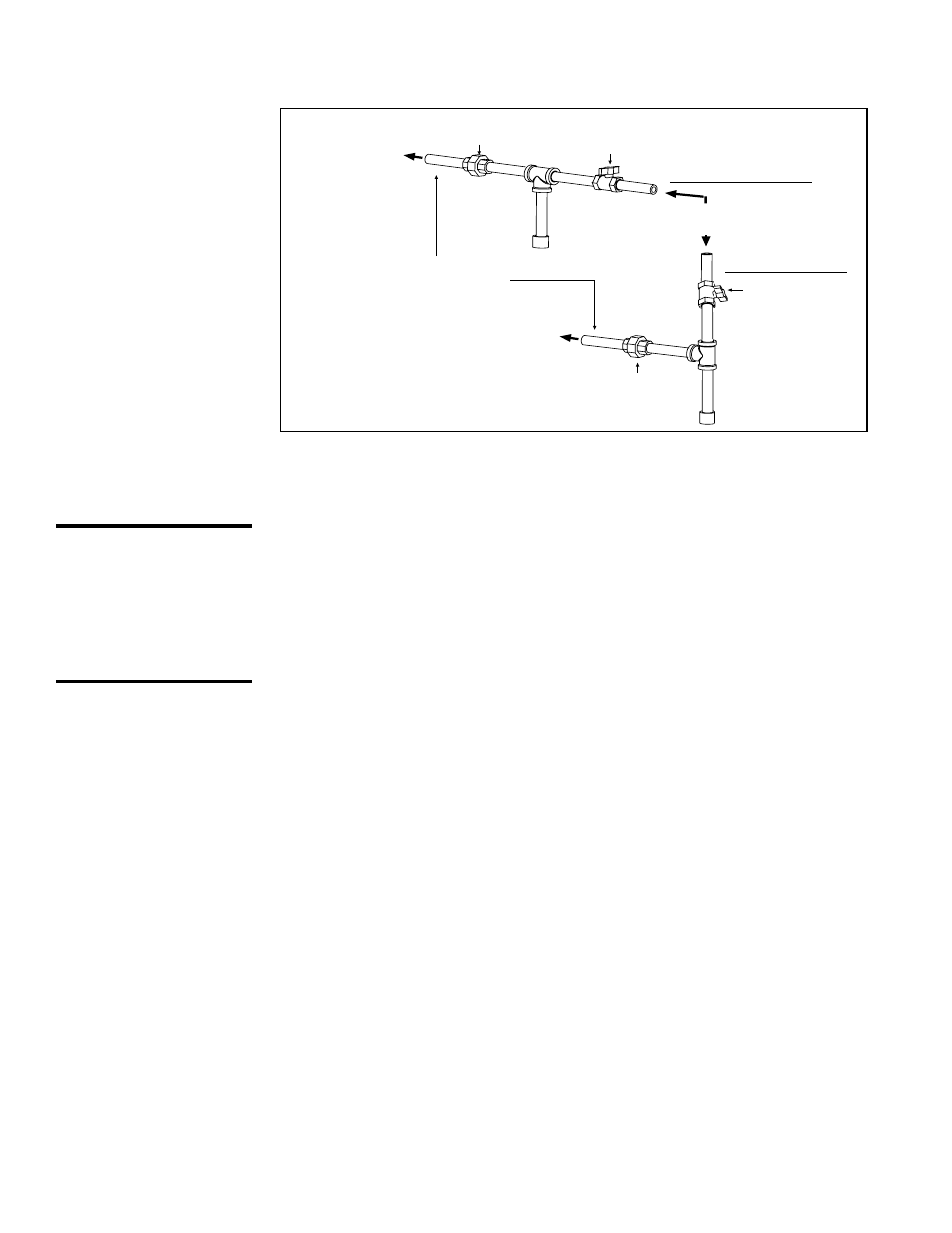

From Gas Supply

(horizontal or vertical)

Manual

shutoff

Pipe nipple extending

outside the cabinet.

Drip

Leg

To Gas Valve

(inside the

cabinet)

To Gas Valve

(inside the

cabinet)

Ground

Joint

Union

Drip

Leg

Ground

Joint Union

Manual shutoff

Horizontal Supply

Vertical Supply

6.1.2 Valve Outlet

or Orifice Pressure

Setting

Measuring valve outlet gas pressure cannot be done until the heater is in oper-

ation. It is included in the steps of the “Check-Test-Start” procedure in Para-

graph 9. The following warnings and instructions apply. Model LDAP 400 has

one gas valve; Model LDAP 800 has two gas valves; and Model LDAP 1200

has three gas valves.

WARNING: Valve

outlet gas pressure

must never exceed

3.5” w.c. for natural

gas and 10” w.c.

for propane gas.

For Natural Gas: When the heater leaves the factory, the combination gas

valve(s) is set so that the valve outlet gas pressure for a single stage valve or

high fire of a two stage valve is regulated to 3.5” w.c. Low fire on a two-stage

valve (Size 400 only) is set to 1.8” w.c. Inlet supply pressure to the heater for

natural gas must be a minimum of 5” w.c. or as noted on the rating plate and a

maximum of 14” w.c.

For Propane: When the heater leaves the factory, the combination gas valve(s)

is set so that the valve outlet gas pressure for a single stage valve or high fire

of a two stage valve is regulated to 10” w.c. Low fire on a two-stage valve (Size

400 only) is set to 5.0” w.c. Inlet supply pressure to the heater for propane gas

must be a minimum of 11” w.c. and a maximum of 14” w.c.

Before attempting to measure or adjust valve outlet gas pressure, the inlet

supply pressure must be within the specified range both when the heater is in

operation and on standby. Incorrect inlet pressure could cause excessive valve

outlet gas pressure immediately or at some future time. If natural gas supply

pressure is too high, install a regulator in the supply line before it reaches the

heater. If natural gas supply pressure is too low, contact your gas supplier.

FIGURE 6 - Gas

connection is at

the pipe nipple that

extends outside the

cabinet.

IMPORTANT: Two pipe

wrenches are required

when installing gas pip-

ing. The gas pipe that is

supplied with the heater

MUST be held with a

pipe wrench to prevent

damage to the heater.

Instructions on How

to Check Valve Outlet

(Manifold) Pressure

-- can only be done

after the heater is

installed.

Instructions

1) Locate the 1/8” output pressure tap on the first valve (See FIGURE 7).

With the manual valve turned off to prevent flow to the gas valve, connect

a manometer to the 1/8” pipe outlet pressure tap in the valve. NOTE: A

manometer (fluid-filled gauge) is recommended rather than a spring type

gauge due to the difficulty of maintaining calibration of a spring type gauge.

2) Open the manual valve and operate the heater. Measure the outlet

pressure of the gas valve. To measure low-stage pressure on a Size 400

unit equipped with a two-stage valve, disconnect the wire from the “HI”

terminal on the valve. (Be sure to reconnect wire after testing.)

Normally when operating at sea level, adjustments should not be

necessary to the factory setting(s). (For high altitude settings, see below.) If

6.0 Mechanical

(cont’d)

6.1 Gas Piping and Pressures (cont’d)

6.1.1 Gas Supply and Pressures (cont’d)