Reznor LDAP Unit Installation Manual User Manual

Page 18

Form I-LDAP, P/N 207733R6, Page 18

Support horizontal vent runs every six feet (1.8M). Support vertical runs of Type

“B” double-wall or Category III vent pipe in accordance with the requirements

of the pipe manufacturer. Support single-wall pipe in accordance with accepted

industry practices. Do not rely on the heater for support of either horizontal or

vertical vent pipe. Use non-combustible supports on vent pipe.

5) Vent System

Support

6) Condensation

Any length of single-wall vent pipe exposed to cold air or run through an

unheated area or an area with an ambient temperature of 45°F or less must

be insulated along its entire length with a minimum of 1/2” foil-faced fiberglass,

1-1/2# density insulation. Where extreme conditions are anticipated, install a

means of condensate disposal.

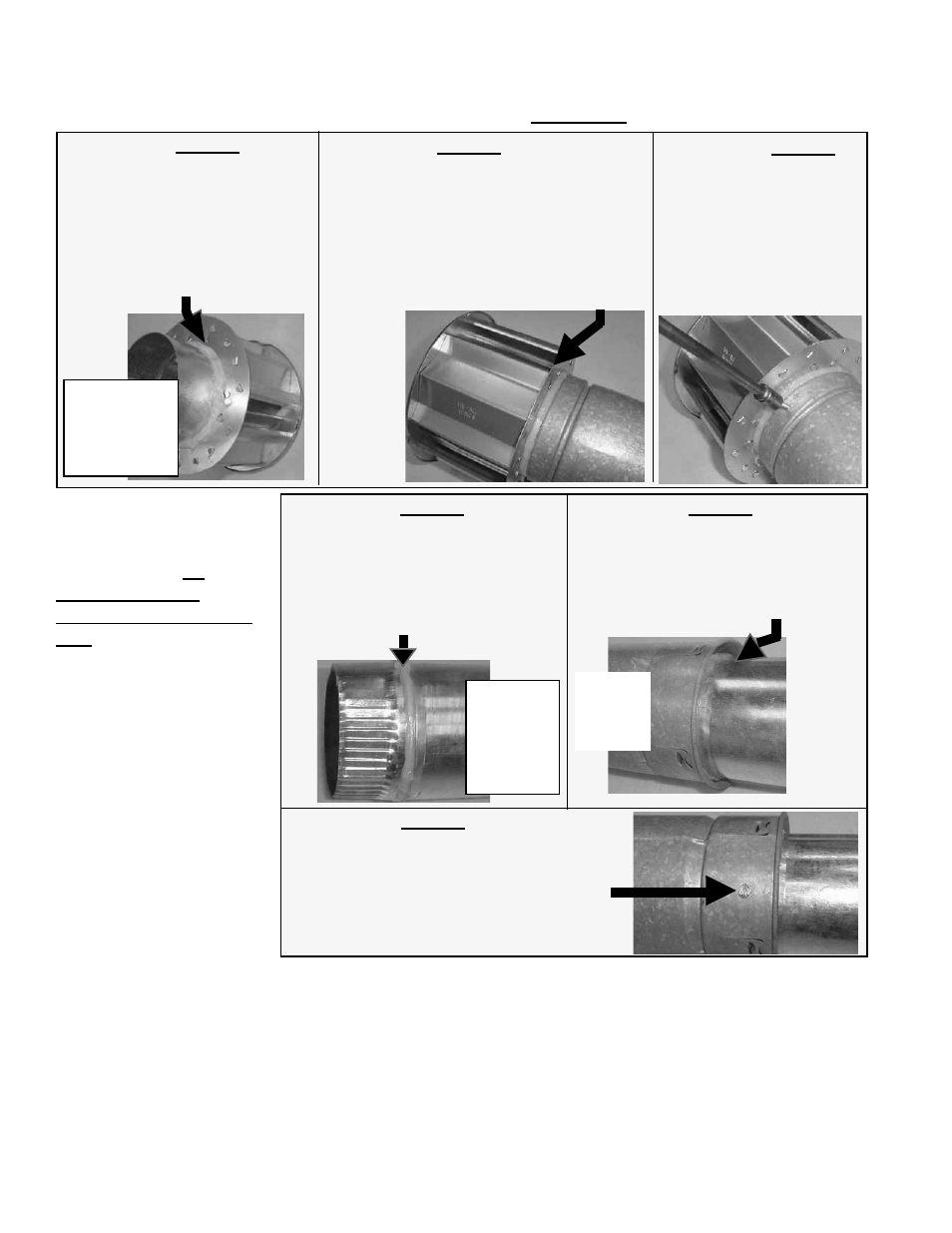

FIGURE 10C -

Attaching Double-

Wall (Type B)

Terminal Pipe to

a Single Wall or

Category III Vent Pipe

Run

Figure 10C - STEP 1

On the single-wall pipe or Cat-

egory III pipe, place a continual

1/4 inch bead of silicone sealant

around the circumference.

Do STEP 2 immediately after

STEP 1.

Figure 10C - STEP 2

Insert the pipe with the sealant

into the inner pipe of the double-

wall pipe until the bead of sealant

contacts the inner pipe creating a

sealed joint.

Figure 10C - STEP 3

Spaced equally around the double-

wall pipe, drill three small holes below

the sealant ring. Insert 3/4 inch long

sheetmetal screws to secure the joint.

Do not over tighten screws.

Vent

Pipe

with

Sealant

Double-

Wall

Pipe

Single-

Wall or

Category

III Vent

Pipe

Figure 10B - STEP 1

Place a continual 3/8” bead

of silicone sealant around the

circumference of the vent cap

collar. This will prevent any

water inside the vent cap from

running down the double-wall

pipe.

Figure 10B - STEP 2

Secure the vent cap to

the double-wall pipe by

drilling and inserting a

3/4” long sheetmetal

screw into the vent

cap collar. Do not over

tighten screw.

Insert the collar on the vent cap inside

the inner wall of the double-wall pipe.

Insert as far as possible. Add addi-

tional silicone sealant to fully close any

gaps between the vent cap and the

double-wall pipe. This is necessary to

prevent water from entering the

double-

wall

pipe.

Figure 10B - STEP 3

Do STEP 2

immediately

following

STEP 1.

FIGURE 10B - Attaching Double-Wall (Type B) Pipe to a Vent Cap

4) Joints and Sealing (cont’d)

6.0 Mechanical

(cont’d)

6.3 Venting (cont’d)