0 maintenance and service (cont’d), Caution: use of eye protection is recommended, 1 maintenance procedures (cont’d) – Reznor LDAP Unit Installation Manual User Manual

Page 36

Form I-LDAP, P/N 207733R6, Page 36

CAUTION: Use of

eye protection is

recommended.

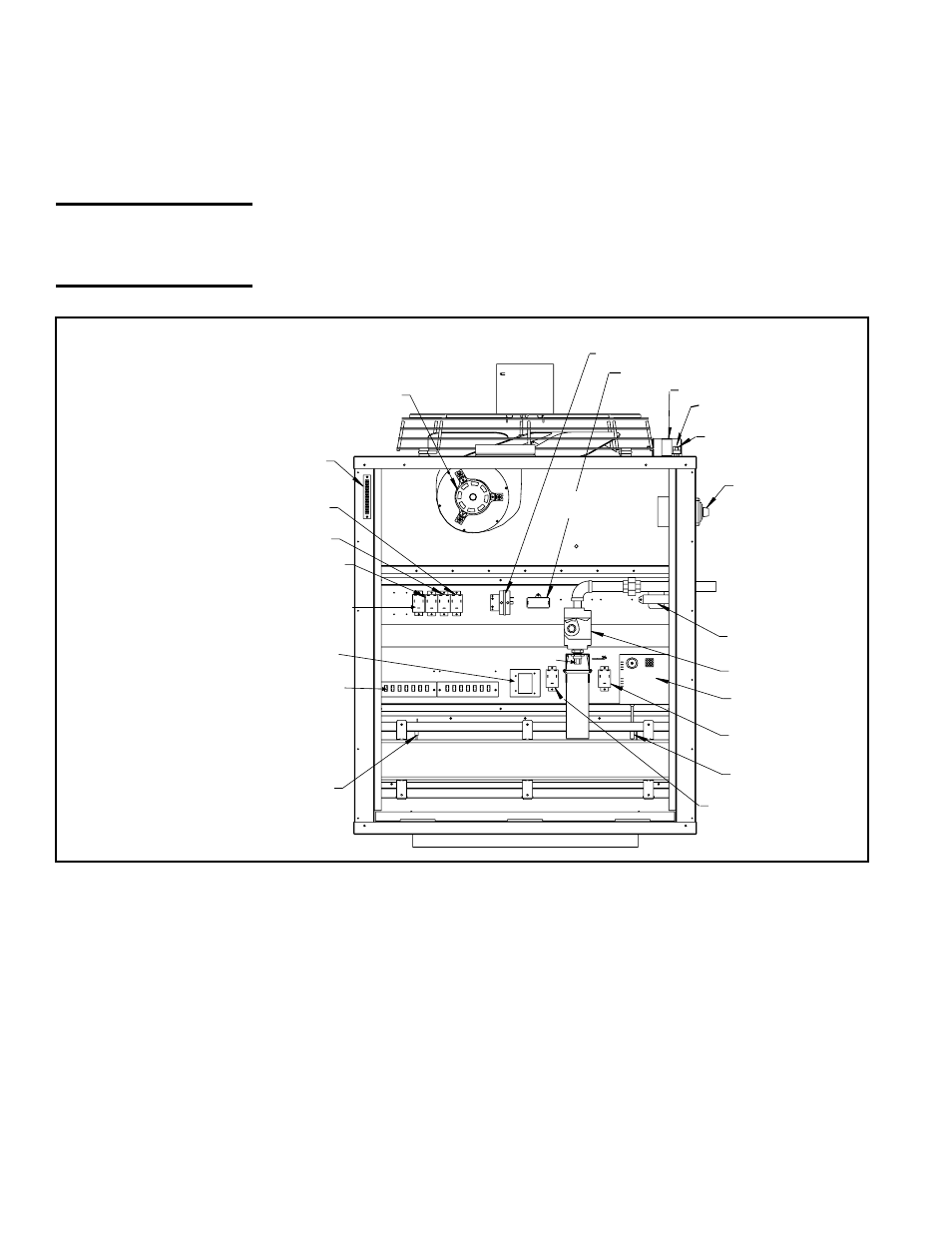

Fan

Motor

Heat Section Pressure Switch

Venter Motor Capacitor

Fan Motor Capacitor

High Limit Control

Disconnect Switch

Transformer

Gas Valve

DSI Control

(Circuit Board)

Fan Permissive

Relay

Ignitor

Heat Permissive Relay

(Models 800 and 1200)

Flame

Sensor

Terminal

Boards

Limit Control

Vent Permissive

Relay (Models 800

and 1200)

Remote Destrat

Relay

Destratification

Relay

24V Thermostat

Terminal Board

Burner Assembly

Heat Section

Venter Motor

Adjustable Destratification

Fan Control

Optional Relay

Burner Orifice

Heat Section

Flue Wrapper

With the burner assembly removed, shine a flashlight on the burner ribbons.

Look for carbon buildup, scale, dust, lint, and/or anything that might restrict flow

through the spaces between the burner ribbons. Holding the burner assembly

so that any foreign material will fall away from the burner, use a stiff bristle

brush to loosen and remove any foreign material(s). If the burner is excessively

dirty, remove one of the burner end caps. Remove the four screws that hold the

end cap to the burner housing. Lightly tap the end cap to remove it.

Clean all foreign material from the burner and venturi. After the burner is thor-

oughly clean, replace the end cap making certain that it is tight against the

burner housing.

Inspect and Clean the

Burner

Inspect the Lower

Portion of the Heat

Exchanger (with

burner assembly

removed)

At the burner flame entrance of each tube, shine a bright light into each heat

exchanger section. With the light shining into the heat exchanger, observe the

outside for visible light. Repeat this procedure with each heat exchanger sec-

tion. If any light is observed, replace the heat exchanger.

of the gas line inside of the heater. Carefully remove the burner orifice and

orifice adapter locking nut. Slide the orifice adapter out through the bracket

on the burner.

6. Remove Burner Assembly

a) Locate the three upper burner body supports. At each support, remove

the one screw that attaches it to the burner shield.

b) Holding the venturi tube, slide the entire burner assembly slightly

upward to disengage the burner from the supports on the bottom. Then

rotate the open end of the venturi tube outward toward the access door

opening. Carefully pull the burner assembly out of the cabinet.

FIGURE 23 - Burner Removal

• Size 400 has 1 burner.

• Size 800 has 2 burners.

• Size 1200 has 3 burners.

NOTE: If any of the

burner components are

damaged or deterio-

rated, replace the burner

assembly.

10.1 Maintenance

Procedures

(cont’d)

10.0 Maintenance

and Service

(cont’d)

10.1.3 Burner Maintenance (cont’d)