Reznor LDAP Unit Installation Manual User Manual

Page 37

Form I-LDAP, P/N 207733R6, Page 37

Ignitor - Refer to FIGURE 22 and locate the ignitor. Disconnect the wire;

remove the screw and the ignitor. Clean the ignitor assembly with an emery

cloth.

CAUTION: Due to

high voltage on

the spark wire and

electrode, do not

touch when ener-

gized. See Hazard

Levels, page 2.

FIGURE 25 -

Ignitor showing

required Spark

Gap measurement

1/8 inch

(3.2mm)

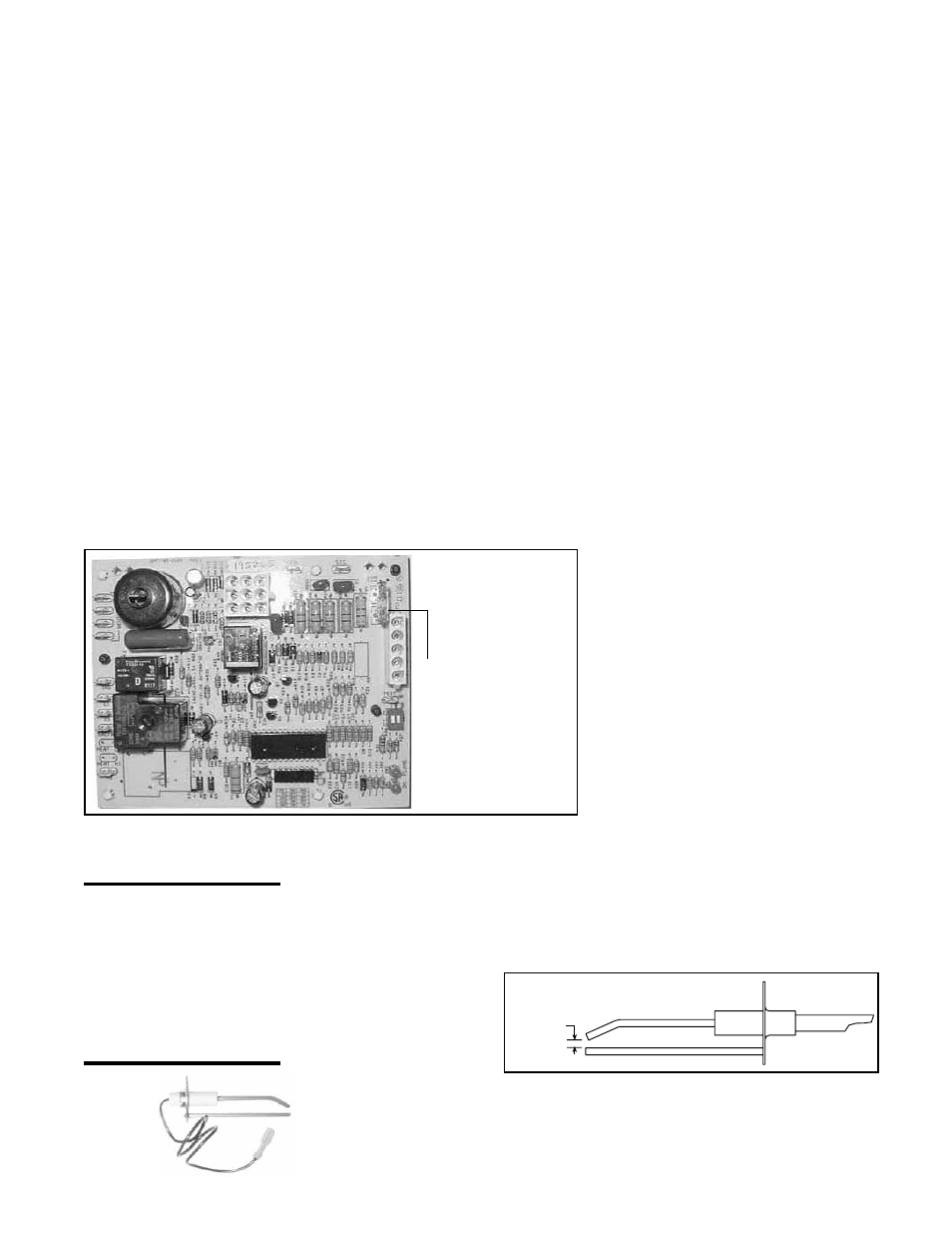

FIGURE 24 -

DSI Integrated

Control Module

(Circuit Board)

Only replaceable

part is a Type

ATC or ATO 3

amp fuse (Color

Code Violet), P/N

201685

10.1.4 Ignition

System

DSI Integrated Control Module (circuit board) - See FIGURE 24. The mod-

ule monitors the operation of the heater including ignition. The only replace-

able component is the 3 amp Type ATC or ATO fuse. If the fuse is blown, the

problem is most likely an external overload.

Correct the problem and replace the

fuse.

Do not attempt to disassemble the con-

trol module. However, each heating sea-

son check the lead wires for insulation

deterioration and good connections.

Size 400 has one control module; Size

800 has two control modules; and Size

1200 has three control modules.

Proper operation of the direct spark igni-

tion system requires a minimum flame

signal of 1.0 microamps as measured by

a microampmeter.

Burner Orifice(s)

A burner orifice usually only needs to be replaced when installing a gas conver-

sion kit. If ordering replacement orifice(s) only, give BTUH content and specific

gravity of gas, as well as the model and serial number of the heater. When

removing or replacing a burner orifice, use two wrenches being careful not to

damage the venturi tube and/or the bracket.

Instructions to Re-Install the Burner (Refer to FIGURE 23.)

1. Attach the Burner Assembly - Holding the venturi tube, slide the entire

burner assembly into position. Align the supports on the bottom with the

slots in the burner shield; sliding the supports into the slots. On the top, re-

attach each burner body support to the burner shield.

2. Attach the Gas Train - Slide the gas train so that the orifice adapter is

through the bracket. Fasten the gas train to the bracket with the locking

nut. Install the gas orifice. Re-connect the wires to the gas valve. Re-

connect the union(s) inside of the control compartment.

3. Reconnect the gas supply at the union outside of the cabinet. Turn on the

gas supply and leak test the connections with leak detecting solution.

4. Close the access panel.

5. Turn on the electric. Check for proper operation.

Re-Install the Burner

For further information and check out procedure on the direct spark ignition

system, refer to Paragraph 8 and the Troubleshooting Flow Chart in Paragraph

10.

Spark gap must be maintained to 1/8”. See

FIGURE 25.

IMPORTANT: When re-assembling, the brown ground wire must remain

attached to the ignitor.

Ignitor