Keypad, Enter code – Interlogix Monitor XL Hardware Guide User Manual

Page 55

22-0375 rev1.1

Monitor ISM/xL™ Hardware Guide

51

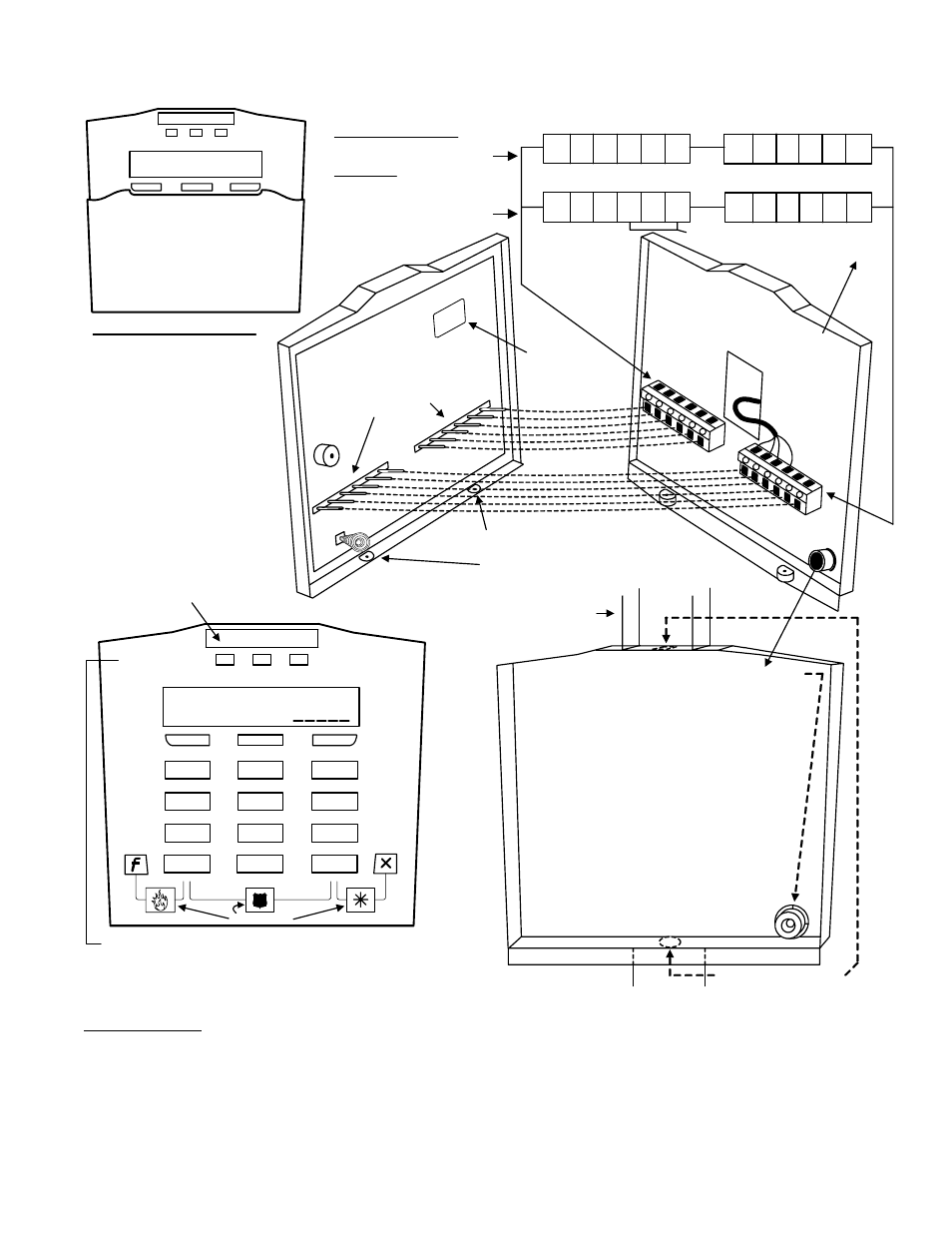

Keypad

1

,

- #

2

ABC

3

DEF

4

5

JKL

6

MNO

GHI

7

8

TUV

9

WXY

PRS

Keypad LEDs

Red Flashing:

Protection ON

Solid: Partial

protection (STAY)

Green On Always

with power present.

Yellow On when

trouble condition

present. Flashing when

there is no AC mains.

Red Green Yellow

ComsLost #50624

ef

Enter

code

4

2 8 2

2

0

Z_Q

X

X

To use the keypad tamper spring as a wall tamper

break out this plastic cylinder inside the back cover.

Screw it to the wall, keeping it in the same hole as it

was attached, so the back cover fits over it.

The plastic cylinder prevents the spring from being

affected by flat objects wedged in behind the

keypad.

The additional keypad base is optional. For

installations using it there is a similar, shorter,

washer style, plastic break out.

Place it behind the plastic cylinder and screw

them down together.

Then place the holes in the base and keypad

backing over top of them.

Fit the spring inside the plastic cylinder part

and secure the keypad front to the keypad

back. The spring compressing should reset

the keypad tamper condition.

Knock outs for rectangular

conduit using additional

keypad base.

Key

pad

Bac

k

Ke

ypa

d F

ron

t

Circuit board pin connectors insert

into fixed terminal blocks on inside

of keypad back. This allows the

keypad to make wire connections

in the terminal blocks.

Terminal

Block

Te

rm

ina

l B

loc

k

Tamper Spring

Sonalert

Cable

After placing the keypad on its back

section, make sure the keypad's securing

screws (supplied) are always I N !

Standard and G-ProxII

1

4

3

2

5

6

PT1 0V PT2 PT3

PT4

1

4

3

2

5

6

A

B

0V

OUT

+12V

0V

Wiegand

1

4

3

2

5

6

D1

D0

1

4

3

2

5

6

A

B

0V

OUT

+12V

0V

0V

PT1

PT2

Keypad Terminal Block Wiring

Module Bus

Module Bus

Ou

tp

ut

Inpu

t 1

In

pu

t 2

Co

m

m

o

n

Wiegand Reader Data 1 and 0.

No reader LED connection.

Wall tamper

knock out

Flip Cover

Serial # sticker

for programming

into Module

Programming.

Apply dealer's logo label (supplied) in

the indented space at the top of the

keypad. Apply the Alert Button labels

as required.

Alert Labels

XX

XX

X

Rectangular Conduit

(Trunking)

Keypad Output

goes negative.

Interface with a

relay or power

supply. Common

their negatives

with keypad 0V.

Module Point Assignment: 8

points.

First point: Fire Alert buttons

Second point: Panic (Hold-

Up) buttons

Third point: Auxiliary Alert

buttons

Points 4 – 7 are hard wire

inputs 1 – 4 on the Standard

and G-ProxII version.

Points 4 – 5 are hard wire

inputs 1 – 2 on the Wiegand

version. All unused points

are skipped.

Point

4 – 7

Point

4 – 5

Point 1

Point 2

Point 3

Ratings:

LCD Keypad with Reader

Input: 12VDC, 110mA

Output: 12VDC, 1x10mA

LCD Keypad

Input: 12VDC, 95mA

Output: 12VDC, 1x10mA

Temp for both: -10°C to

+55°C (14°F to 131°F) @

93%

Future

Future

3 Keypad Versions

•

LCD Keypad P/N 111-3610 (white), 111-3620 (gray): standard keypad includes 3 programmable alert button inputs, 4 hardwire

alarm input points and 1 output point.

•

LCD Keypad with RF reader P/N 111-3611 (white), 111-3621 (gray): keypad includes 3 programmable alert button inputs, 4

hardwire alarm input points and 1 output point. Includes a built-in RF G-Prox reader.

•

LCD Wiegand Keypad P/N 111-3612 (white), 111-3622 (gray): keypad includes the capability to connect an external Wiegand

reader to it. Keypad includes 3 programmable alert button inputs, 2 hardwire alarm input points and 1 output point.

Refer to Installation Instructions P/N 21-3610 for further information.