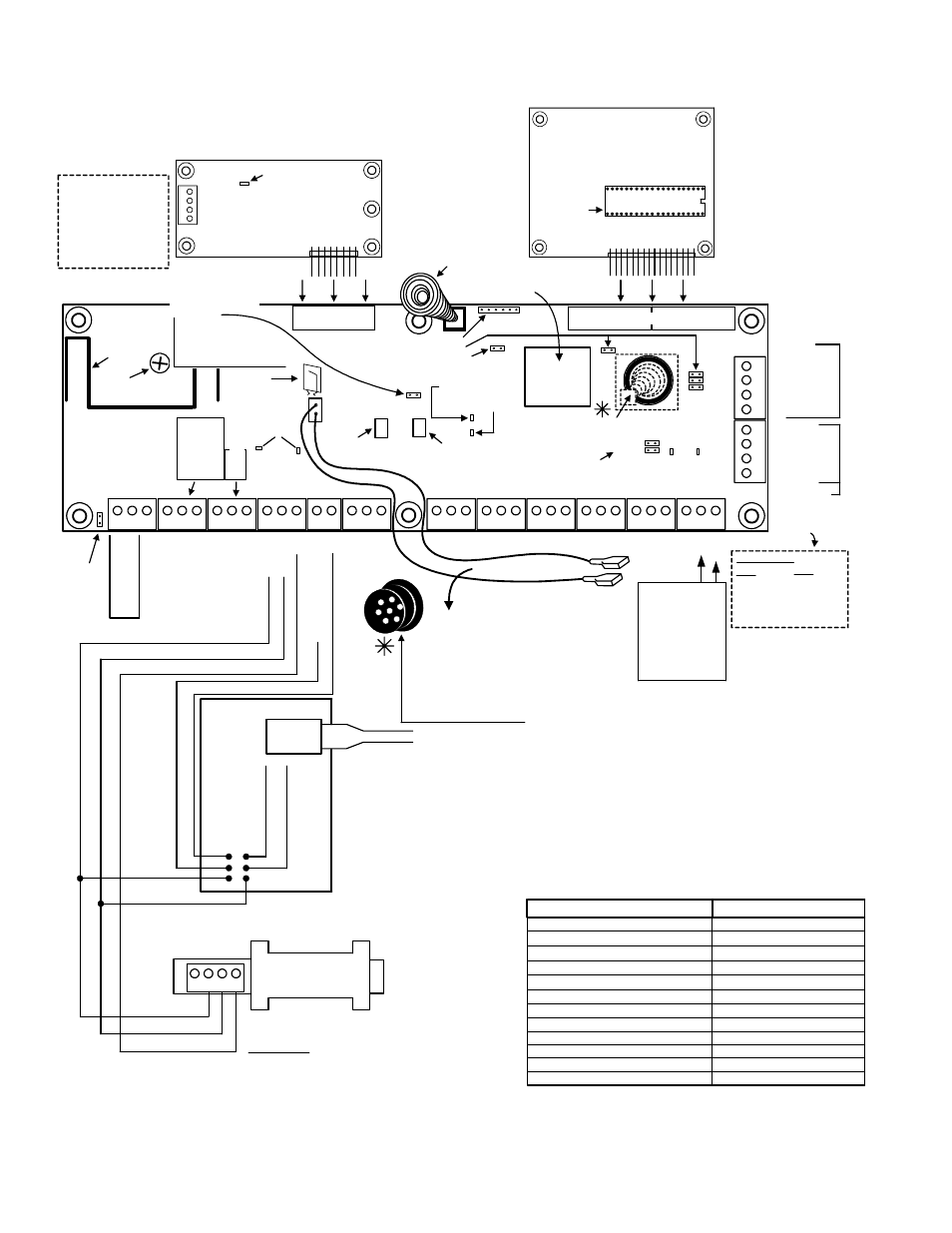

Main controller, Main control module, 48 monitor ism/xl™ hardware guide – Interlogix Monitor XL Hardware Guide User Manual

Page 52: Ip module network

48

Monitor ISM/xL™ Hardware Guide

22-0375 rev1.1

Main Controller

3

1 2

TB2

TB1

3

1 2

3

1 2

3

1 2

1 2

3

1 2

3

1 2

3

1 2

3

1 2

3

1 2

3

1 2

3

1 2

3

12

4

3

12

4

TB3

TB4

TB5

TB6

TB7

TB8

TB9

TB10

TB11

TB12

(+)12V

(

-

)0V

Data B

Data A

bla

ck

red

yello

w

gre

en

(+)12V

(

-

)0V

Data B

Data A

Relay 1

Re

la

y

2

Ea

rt

h

G

N

D

AC

M

a

in

s

AC

M

a

in

s

N

o

rm

a

lly O

p

en

1

Co

mm

on

1

N

o

rm

all

y

Cl

os

ed

1

No

rm

al

ly

O

p

en

2

Com

m

on 2

No

rm

al

ly

Cl

os

e

d

2

Hos

t A

0V

Ho

s

t B

A

u

xi

lia

ry (

+

)1

2

V

D

C

A

u

xi

lia

ry (

+

)1

2

V

D

C

0V

0V

V BU

S

P1

0V

P2

P3

0V

P4

P5

0V

P6

P7

0V

P8

P9

0V

P1

0

0V

P11

P12

Mo

dule B

u

s

(SN

APP)

Mo

dule B

u

s

(SN

APP

)

Input Protection Points

Rear Tamper on back

of board.

Mod Bus (SNAPP)

reset-able fuse.

Battery

power reset-

able fuse.

Momentarily jumper

after a battery has been

connected and there is

no AC mains available.

These unjumpered

connectors for factory

use only. Do not jumper.

Relay 1 is for large

applications such

as a siren. Relay 2

is for smaller ones

such as a strobe.

For module

trunk line.

Grn

TX

Yel

RX

Host

LEDS

Yel

RX

Grn

TX

SNAPP

LEDs

Status Grn LED

Trouble Yel LED

16V

40VA

(+)

(

-

)

Battery Connectors

Auxiliary power

reset-able fuse

(+)

(

-

)

Program Reset

Jumpers

TB13

TB14

Use shielded

cable.

Thi

s

unju

m

pered

c

onnector n

o

t used.

D

o

not j

u

mper.

Battery

leads

plug

TB4 RS485 Host

Communications To

connect to an external

modem, use the 650-

9061 Converter. The

main control board can

not dial out to the

Director software.

Module Bus (shielded)

120-3401

120-3405

Preferred (24 AWG)

FT4

FT6

120-3408

120-3409

ULC (22 AWG)

Terminate shield at

control box earth

ground. Loop through

modules. Do not

terminate at end of line.

Anti-Attack Bushing Cap (p/n 364-5102) covers the rear

tamper spring. It fits inside an “ O “ Ring Bushing (p/n 364-

5103) that fits inside the metal cabinet’s rear wall, anti-tamper

spring, knock-out. Leave the O ring bushing and cap IN if the

rear tamper is not used. If the rear tamper is used, remove the

cap and the O ring with the edge of a flat screw driver. Discard

the O ring. Align the cap to insert in the tamper spring, knock-out

hole on the control cabinet back. Screw the cap by its center hole

to the mounting surface. Place the control cabinet over it,

allowing the rear tamper spring to fit inside the cap. The cap will

insert in the metal cabinet’s tamper spring, knock-out hole.

Complete securing the metal cabinet to the mounting surface.

Position the battery with its terminals

on the left in the control box. Secure

the 12V 7.0Ah battery with the

securing bracket (p/n 232-2605) and

screws from the supplied accessories

kit. For a 17Ah battery bracket, order

kit 250-3617.

during service,

heat sink may

be hot.

To battery 12V 7.0AH

p/n 133-4788

Factory set

Do not adjust

Expansion

Modem

Memory Expansion Socket

Socket

Manual Battery

Re-start

E non volatile memory.

Power loss will not lose

program.

2

Reserve

for service

keypad.

Unpack the Modem and Memory Expansion Modules, if included, in package. With

power disconnected, plug them into the main control board’s Modem and Memory

Expansion Sockets. Secure them to their control cabinet stand-offs with the supplied

screws.

The control box tamper

spring is included in the

accessories kit. Fit it on

to the main board cover

tamper button.

NOTE:

Main Control Module

3

12

4

Seized Tip

Seized Ring

Tip

Ring

Off Hook

LED

North American Modem

Example:

Feature Expansion Module

Memory

Expansion

Socket

Connecting 2 un-

programmed

keypads on the

module trunk will

cause one to

become a service

tool and the other

will not be

accessible. All

programmed

keypads will

function normally.

NOTE: Remove enclosure knock-outs before installing circuit boards.

NOTICE: Use

minimum 26AWG

UL/CSA/or

equivalent

approved

telephone cable.

Turns on when

unit dialing out

(Bell 103)

CAUTION:

P12 is Bell

Return (Siren

Tamper) in UK

configuration. It

is a regular

input in all other

configurations.

Module Description (voltage 12VDC) Current Rating (mA)

LCD Keypad with Reader

North American Modem

8 Output STU

– 110 (includes 10mA /1 o/p)

Worldwide Modem with 8 o/p STU

Feature Expansion Board

– 45

– 115 (includes 10mA / 8 o/p)

– 145 (includes 10mA / 8 o/p)

– 100

LCD Keypad

– 95 (includes 10mA /1 o/p)

8 Transistor Output Board

– 135 (includes 10mA / 8 o/p)

8 Relay Output Board

– 155

16 Point Expander Board

– 100 (includes 10mA / 2 o/p)

8 Input VBUS Expander Board

– 35

8 Point Expander Board

– 85

Power Supply Board

– 50

CFG0

CFG1

MAIN CONTROL MODULE RELAY OUTPUTS

TB2 Relay 1:

5AMPS Resistive, 1 AMP Inductive.

TB3 Relay 2: 1 AMP Resistive,

0.1 AMPS Inductive.

RS485 Communication Cable

Cable Shield: Connect to the chassis/earth ground

at main control box (do not ground at the PC)

P/N 120-3401 (24 AWG, 4wires, shielded)

1

4

3

2

P/N 650-9061

(

+

)12V

(

-

)0V

Data B

Data A

black

green

white

Data A

Data B

(

-

)0V

(+

) 12VDC

O

range

R

S

232 R

X

(S

IP

)

Yellow RS485 B (Dir Sftwr)

Bl

u

e

R

S

232 TX

(S

IP

)

Green

RS485 A

Re

d

Bl

a

c

k

(

-

)

N

eg. G

N

D

IP Module

Network

RS485 Converter

Direct Connect to the Director Software PC

DB9

Plug in to PC

Comms Port

Comms to the Director

Software PC

(Director Sftwr)

S

e

c

u

rity

IP

Re

c

e

iv

e

r