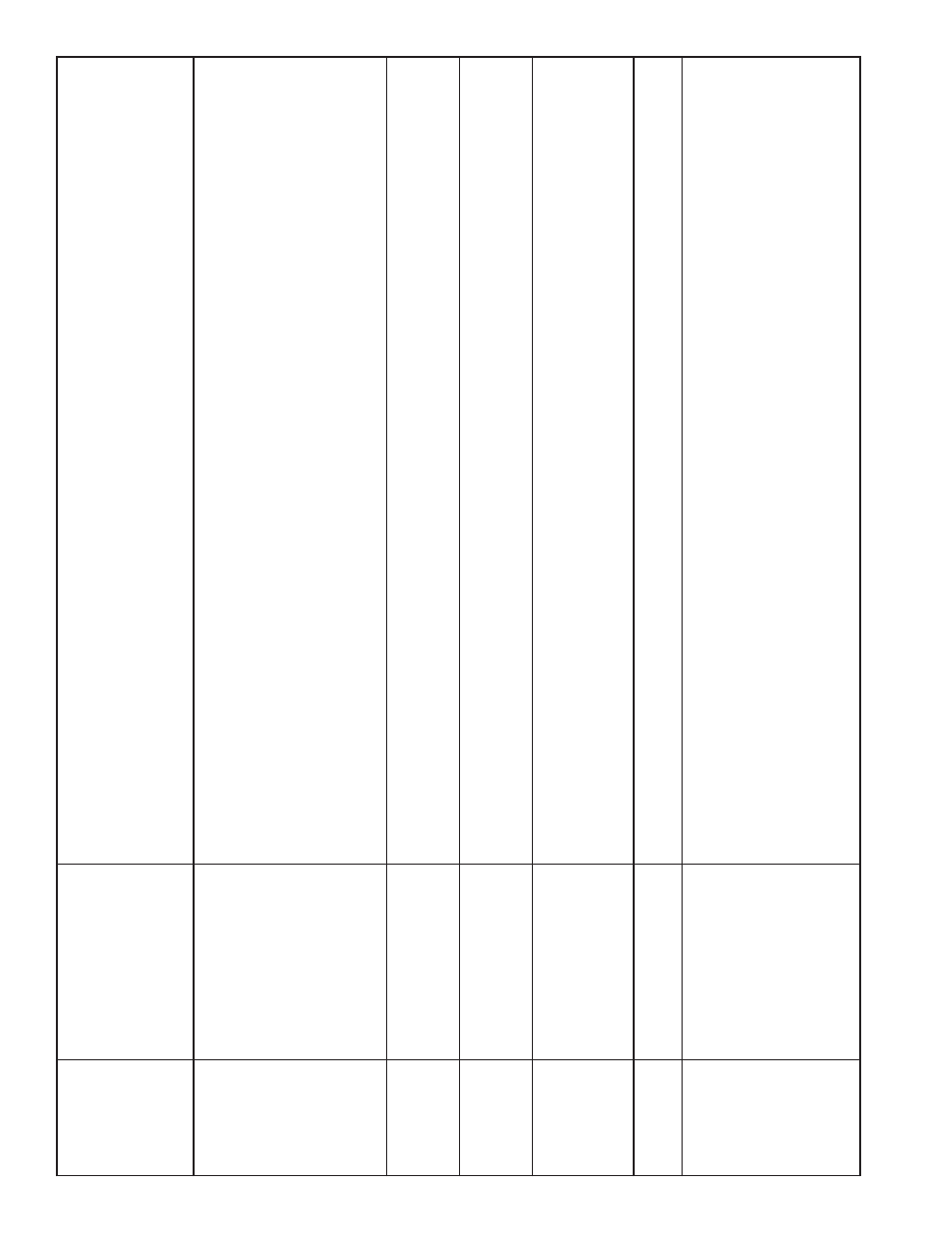

E 31, E 32, E 35 – AERCO Esteem O&M Manual User Manual

Page 89: E 36, E 37, E 40, E 44

83

GF-125

E 31

Boiler Supply

Temperature Sensor

Control module detects a short or jumped out condition of the boiler supply (outlet) temperature

sensor.

•

Inspect the boiler supply temperature sensor and wiring, ensure it is secure and in good

condition, replace as needed.

•

Replace the sensor and wiring if problem persists.

E 32

Boiler Return

Temperature Sensor

Control module detects a short or jumped out condition of the boiler return (inlet) temperature

sensor.

•

Inspect the boiler return temperature sensor and wiring, ensure it is secure and in good con-

dition, replace as needed.

•

Replace the sensor and wiring if problem persists.

Control module detects a short or jumped out condition of flue temperature sensor.

•

Inspect the flue temperature sensor and wiring, ensure it is secure and in good condition.

•

Replace the sensor and wiring if problem persists.

E 35

Flue Temperature

Sensor

Control module detects the boiler supply (outlet) temperature sensor as an open circuit.

•

Inspect the boiler supply temperature sensor and wiring, ensure it is secure and in good

condition, replace as needed.

E 36

Boiler Supply

Temperature Sensor

Control module detects the boiler return (inlet) temperature sensor as an open circuit.

•

Inspect the boiler return temperature sensor and wiring, ensure it is secure and in good con-

dition, replace as needed.

E 37

Boiler Return

Temperature sensor

Control module detects the flue temperature sensor as “open”, which is typically an improper or

missing connexion at the sensor.

•

Inspect the flue temperature sensor and wiring, ensure it is secure and in good condition.

•

Replace the sensor if problem persists.

E 40

Flue Temperature

Sensor

•

Reset the boiler control module and retry ignition sequence and boiler operation. If problem

continues, contact AERCO International Technical Support for additional assistance.

E 44

Internal Failure

Control module

detects the flue tem-

perature exceeding

the 250

ºF limitation of

the boiler.

•

Heat exchanger flue ways may need cleaning. See Chapter 18

Maintenance Procedures for

cleaning the flue side of the heat exchanger.

•

Isolate the boiler from the boiler system piping and drain the boiler heat exchanger. Flush

the boiler heat exchanger several times, checking the discharge water for signs of scale

or sediment.

•

Inspect the flue temperature sensor and wiring, ensure it is secure and in good condition,

replace as needed.