B 25, B 26, B 28 – AERCO Esteem O&M Manual User Manual

Page 81

75

GF-125

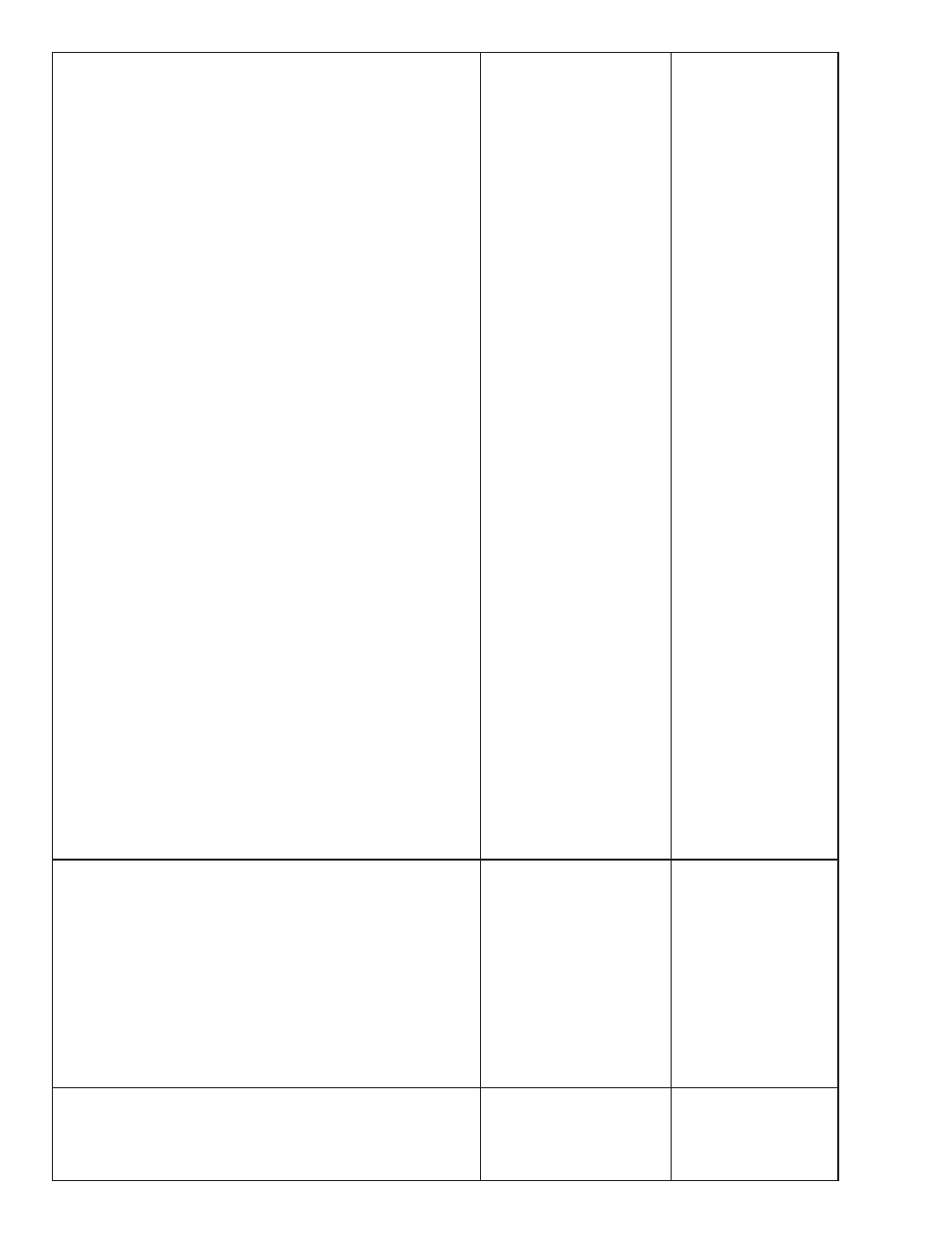

b 25

High Temperature Limit,

Boiler Supply

If the primary boiler

supply water tempera-

ture rate of increase is

deemed too quick, the

burner will shut down for

a 3 minutes If the condi-

tion is not corrected dur-

ing the next cycle, the

burner shut down period

will increase an additional

minute. The boiler will

continue for 5 cycles until

a “hard” lockout occurs.

•

Occurs if the flow rate on the boiler is too low. Check the following:

•

Boiler and heating system are filled with water and the LWCO is operating properly.

•

Boiler and heating system have been properly purged and there is no trapped air.

•

Inspect heating system piping and its components. Ensure piping is per the recommenda-

tions given in the installation instructions or other approved design configuration

•

Pump is properly sized for flow rate required based on the head loss of the system. See page 91

for pump curves and boiler pressure drop. Consult the circulator manufacturer for additional pump

curve data or for assistance in sizing a circulator properly.

•

Boiler space heating circulator is operating properly.

•

Verify 120V at the circulator wiring in the circulator junction box. If no voltage is mea-

sured, check circulator wiring and connections.

•

Verify 120V at the 120V terminal strip along terminals 1 and 2 inside the boiler enclosure.

Check circulator wire harness from the boiler to the circulator if necessary.

•

Verify the external DHW circulator is operating properly.

•

Verify 120V at the circulator wiring in the circulator junction box. If no voltage is mea-

sured, check circulator wiring and connections.

•

Verify 120V at the 120V terminal strip, terminals 4 and 5 inside the boiler enclosure.

Check circulator wire harness from the boiler to the circulator. Replace if necessary.

b 26

LWCO Device

If Control module deter-

mines LWCO device is

open boiler will shut

down until the condition

is corrected. Once cor-

rected the boiler will re-

start after 150 seconds.

•

Check the pressure gauge on the boiler and ensure the system is at minimum 10 psig.

•

Ensure proper operation of the boiler make up system and fill valve.

•

Check continuity across the LWCO terminals for closed contacts if the boiler system pres-

sure gauge reads 10 psig or greater.

•

Replace the LWCO device if the continuity shows an open circuit and the system pres-

sure is 10 psig or greater.

•

Check the wiring and contacts from the LWCO to Control module terminals if the continu-

ity check shows a close circuit.

b 28

Blower Assembly

Occurs if the blower

does not start. during

the ignition sequence.

Boiler display will show

code

5

during the ignition

sequence.

•

Disconnect the connector at the blower. Restart the boiler sequence and check for 35Vdc at

the connector between the black and white wires (pin 1 & 5).

•

If 35Vdc is present at the connector, reconnect the wire harness to the blower and ensure

a secure connection. Replace the blower assembly if problem is not resolved.

•

If 35Vdc is not present at the connector, inspect the wiring harness. Replace the wire har-

ness, if there is any damage visible

•

Contact AERCO International Technical Support if problem is not resolved.