Warning, 43 first run check of the unit and system, First run check of the unit and system – AERCO Esteem O&M Manual User Manual

Page 49: Gf-125

43

First Run Check of the Unit and System

WARNING!

T

HE

COMBUSTION

TESTING

AND

ADJUSTMENTS

MUST

BE

PERFORMED

BY

A

QUALIFIED

INSTALL

-

ER

,

SERVICE

AGENCY

OR

THE

GAS

SUPPLIER

.

A

LL

COMBUSTION

MEASUREMENTS

MUST

BE

PERFORMED

WITH

CALIBRATED

EQUIPMENT

TO

ENSURE

PROPER

READING

AND

ACCURACY

.

Test for CO2 or O2 and for CO during

high fi ring rate. To manually place the

boiler into high fi re mode, refer to page 49.

The combustion reading should be within

the range listed in Table 2. The CO level

should not exceed 100 ppm when com-

bustion is correct.

WARNING!

T

HE

COMBUSTION

LEVELS

SHOULD

BE

MEAS

-

URED

AT

HIGH

FIRING

RATE

,

REFER

TO

PAGE

49

OF

THE

E

STEEM

399 L

OW

NO

X

CONTROL

SECTION

ON

HOW

TO

SET

THE

FIRING

RATE

. I

F

THE

COMBUSTION

LEVELS

ARE

NOT

WITHIN

THE

RANGE

GIVEN

IN

T

ABLE

2

FOR

THE

FIRING

RATE

,

SHUT

THE

BOILER

DOWN

AND

CONTACT

AERCO

I

NTERNATIONAL

E

NGINEERING

D

EPARTMENT

.

F

AILURE

TO

COMPLY

WITH

THIS

REQUIREMENT

COULD

RESULT

IN

SEVERE

PERSONAL

INJURY

,

DEATH

OR

PROPERTY

DAMAGE

.

First Run Check of the Unit and

System

Check Boiler Piping.

Check Boiler system piping and compo-

nents for leaks. If found, shut down the

unit and repair immediately.

Purge remaining air from the system

piping. Air in the system piping will inter-

fere with circulation creating heat distri-

bution problems and system noise.

Check Vent Piping and Combustion Air

Piping.

Check for gas-tight seal at every connec-

tion and seam of the venting and combus-

tion air piping.

WARNING!

V

ENTING

SYSTEM

MUST

BE

SEALED

GAS

-

TIGHT

TO

PREVENT

FLUE

GAS

SPILLAGE

AND

POTEN

-

TIAL

CARBON

MONOXIDE

EMISSIONS

,

WHICH

WILL

RESULT

IN

PERSONAL

INJURY

OR

DEATH

.

Check Gas Piping

Check around the unit for gas odor fol-

lowing the procedure on page 40 of this

manual.

WARNING!

I

F

ANY

GAS

LEAKS

ARE

FOUND

OR

SUSPECTED

,

SHUT

THE

UNIT

DOWN

IMMEDIATELY

. L

OCATE

AND

REPAIR

ALL

LEAKS

. D

O

NOT

OPERATE

THE

UNIT

UNTIL

THE

LEAK

IS

CORRECTED

. F

AILURE

TO

COMPLY

WITH

THIS

PROCEDURE

COULD

RE

-

SULT

IN

PERSONAL

INJURY

,

DEATH

OR

PROPER

-

TY

DAMAGE

.

Verify Flame Pattern and Combustion

Check the fl ame pattern through the

inspection port of the heat exchanger.

The fl ame should be blue and stable. The

fl ame should be the length of the burner

head openings.

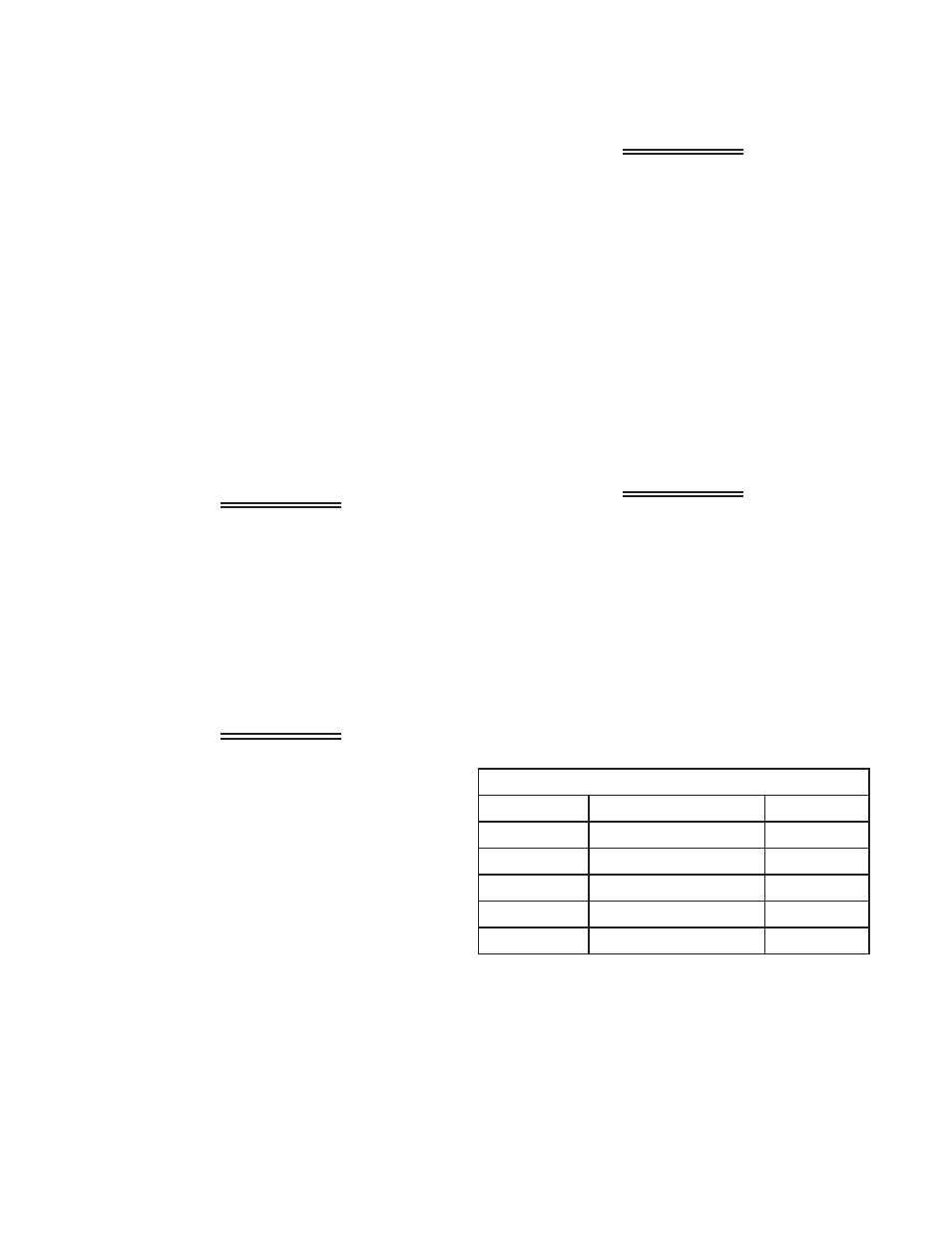

Table 2: Recommended Combustion Levels

Natural Gas

Propane

O2 Min.

2.30%

3.70%

O2 Max.

5.30%

5.20%

CO2 Min.

8.80%

10.00%

CO2 Min.

10.50%

11.00%

CO Max.

100 ppm

100 ppm

GF-125