Chapter 7 gas piping, Warning, 29 gas supply piping connection – AERCO Esteem O&M Manual User Manual

Page 35: Gf-125

29

Gas Supply Piping Connection

N

OTICE

The gas supply piping must be installed

in accordance to all local, state and na-

tional codes and utility requirements.

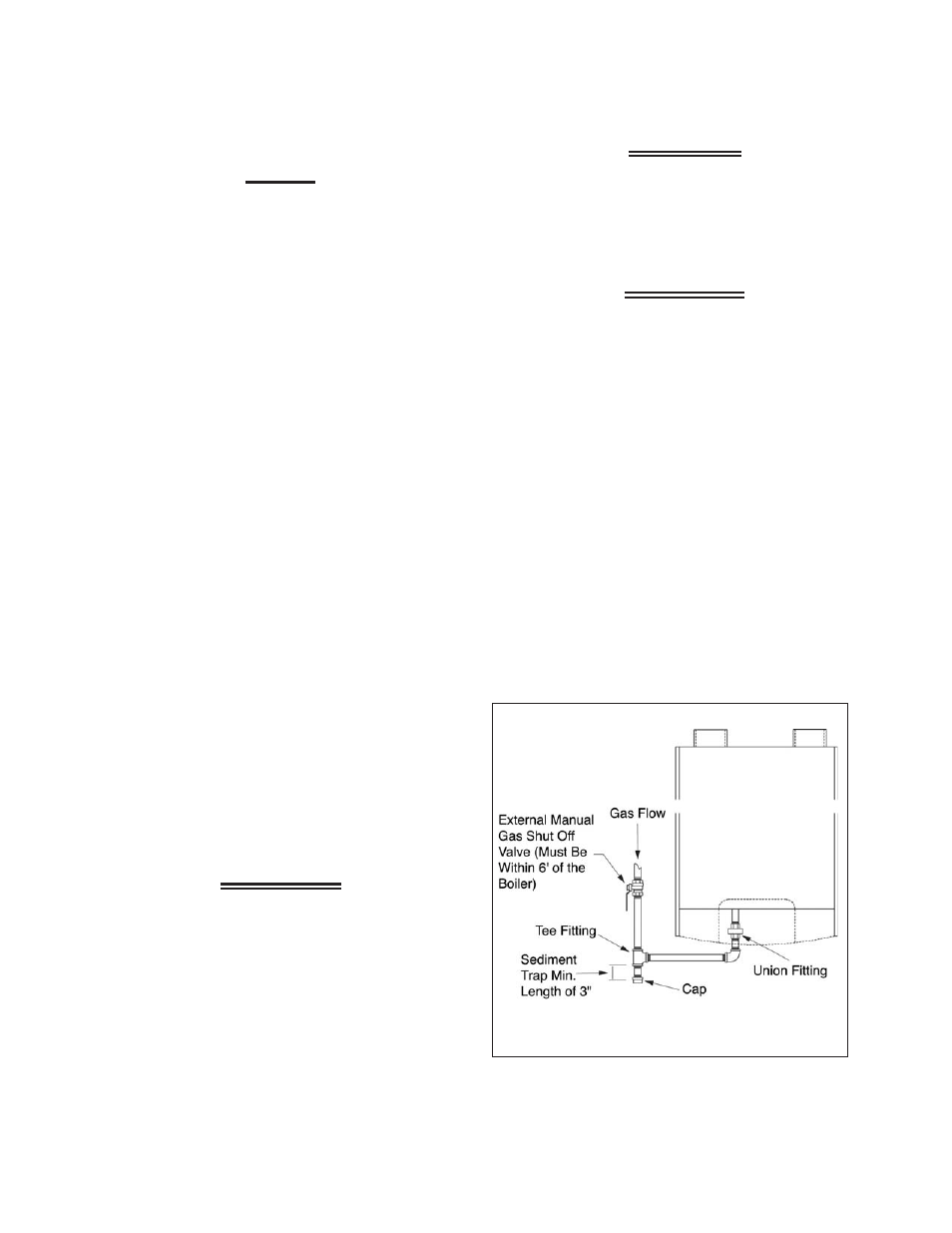

1. Install a 1” NPT for the pipe union at the

factory supplied gas nipple, for ease of

service.

2. Install a manual shutoff valve in the gas

supply piping as shown in Figure 17. For

Canadian installations the main shutoff

valve must be tagged and identified by

the installer

3. Install a sediment trap (drip leg) on the

gas supply line prior to connecting to the

Esteem 399 Low NOx gas train as shown

in Figure 17.

4. Support the gas piping using hangers. Do

not support the piping by the unit or its

components.

5. Purge all air from the gas supply piping.

6. Before placing the boiler into operation,

test all connections for leaks.

• Close the manual shutoff valve during

any pressure test with less than 13”w.c..

• Disconnect the Esteem 399 Low NOx

and its gas valve from the gas supply

piping during any pressure test greater

than 13”w.c..

WARNING!

D

O

NOT

CHECK

FOR

GAS

LEAKS

WITH

AN

OPEN

FLAME

. U

SE

A

GAS

DETECTION

DEVICE

OR

BUB

-

BLE

TEST

. F

AILURE

TO

CHECK

FOR

GAS

LEAKS

CAN

CAUSE

SEVERE

PERSONAL

INJURY

,

DEATH

OR

SUBSTANTIAL

PROPERTY

DAMAGE

.

7. Use pipe dope compatible with natural

and propane gases. Apply sparingly only

to the male threads of pipe joints so that

pipe dope does not block gas flow.

WARNING

F

AILURE

TO

APPLY

PIPE

DOPE

AS

DETAILED

ABOVE

CAN

RESULT

IN

SEVERE

PERSONAL

IN

-

JURY

,

DEATH

OR

SUBSTANTIAL

PROPERTY

DAM

-

AGE

.

WARNING!

U

SE

A

TWO

-

WRENCH

METHOD

OF

TIGHTENING

GAS

PIPING

NEAR

THE

UNIT

AND

ITS

GAS

PIPING

CONNECTION

. U

SE

ONE

WRENCH

TO

PREVENT

THE

BOILER

GAS

LINE

CONNECTION

FROM

TURN

-

ING

AND

THE

SECOND

TO

TIGHTEN

ADJACENT

PIPING

. F

AILURE

TO

SUPPORT

THE

BOILER

GAS

PIPING

CONNECTION

COULD

DAMAGE

THE

GAS

LINE

COMPONENTS

.

Figure 17: Recommended Gas Supply Piping

Chapter 7

Gas Piping

GF-125