E-00, E 02 – AERCO Esteem O&M Manual User Manual

Page 84

78

GF-125

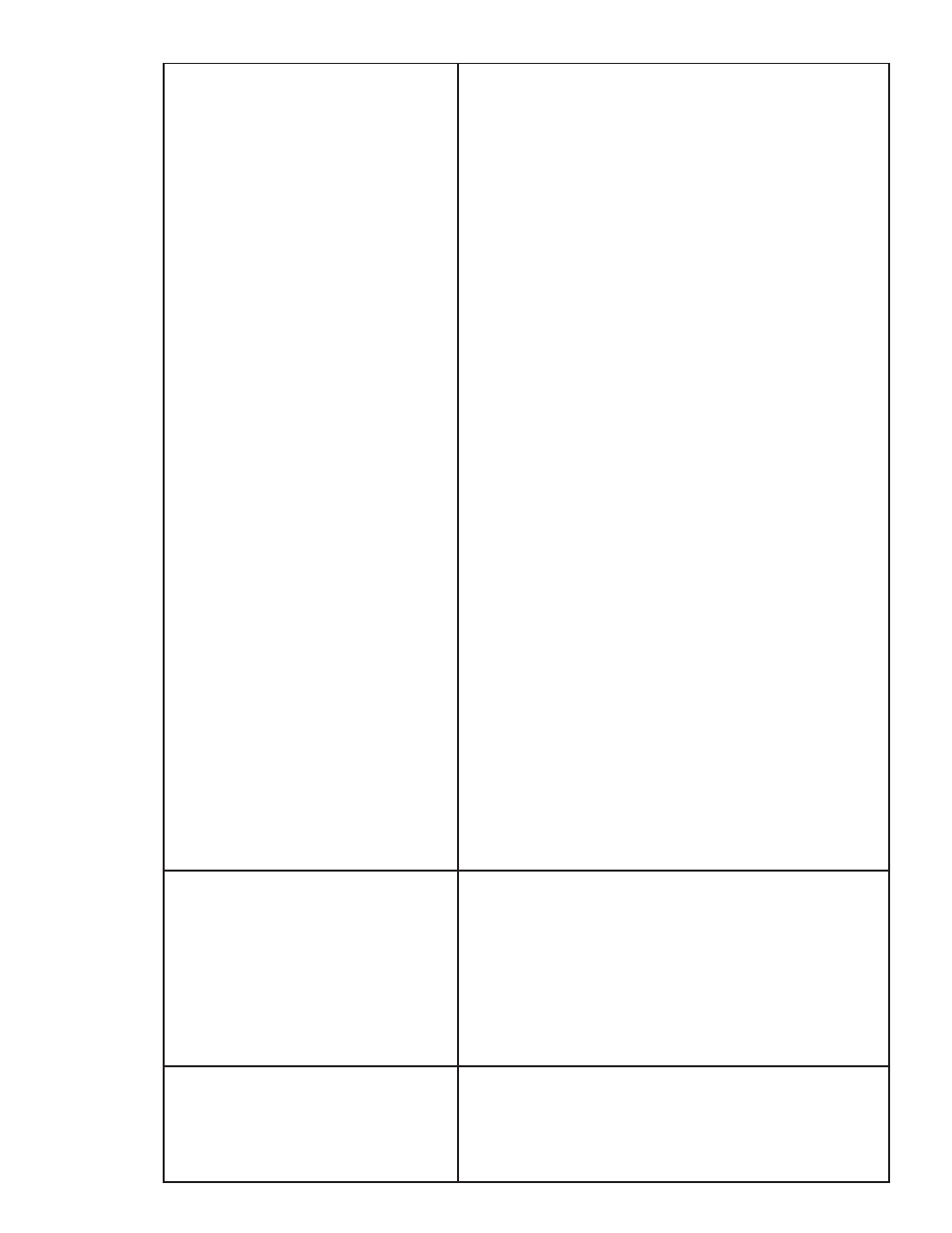

Hard Lockout Codes

The boiler will display a Hard Lockout with an E as the first digit on the left of display followed by a two-digit code. The b

oiler must be

manually reset by pressing the RESET button on the display once the condition has been corrected. A Hard Lockout will occur wh

en

boiler conditions, that are considered critical in terms of safety, are not met or exceeded.

E-00

Flame Detection

Error

Control module

detects a burner

flame prior to the igni-

tion sequence.

•

This problem maybe related to the burner operating too hot due to poor combustion. Flame

pattern and combustion should be tested at both high fire and low fire inputs. See page 49

regarding high and low fire input procedures.

See Table 2 on page 43 for combustion require-

ments.

•

If the application is propane, verify the propane orifice size is 0.264” (6.7mm). Ensure the

propane orifice is properly seated in the gas valve gasket.

•

Inspect the burner head through the burner sight port during shut down sequence of the

boiler.

•

If the flame remains after shut down sequence, the gas valve maybe leaking. Verify the

gas pressure is less than 13 inches w.c. If the gas pressure is less than 13 inches w.c.,

replace the gas valve.

E 02

Failed Ignition Error

Boiler has failed to

establish flame detec-

tion during the igni-

tion sequence.

The lockout will occur after 5 tries.

•

No ignition spark during the ignition sequence:

•

Check ignition electrode cable, electrode boot connector and all connections. Replace

cable if damaged.

•

Inspect insulation of electrode cable and electrode igniter. Replace as needed.

•

Use a ground continuity check to verify a good ground between Control module ground &

burner mounting plate.

•

Spark present during the ignition sequence, but no flame:

•

Verify the manual shutoff valve on the gas supply piping is in the OPEN position.

•

Verify the gas pressure at the inlet of the valve during ignition sequence. Ensure the gas

pressure maintains a minimum 5 inches w.c during ignition sequence. Note: All gas appli-

ances within the building should be operating during this measurement.

•

Verify all gas piping is free of obstructions and has been purged of all air.

•

Check the gas meter for indications of gas flow during the ignition sequence.

•

Remove the ignition electrode to inspect. Replace the electrode if fouled or damaged.

•

Replace the gas valve rectifier cable.

•

Remove and inspect gas valve and venturi gas ports. Ensure ports are obstruction free.

•

Contact AERCO International Technical Support for additional assistance.