Overview, Cascadeable ez-screen – Banner EZ-SCREEN Low-Profile Safety Light Curtain Systems User Manual

Page 69

P/N 13348

67

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Overview

P/N 140044 rev.

E

67

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

EZ-SCREEN LP

Instruction Manual

Cascadeable EZ-SCREEN

Remote Fixed Blanking Programming Procedures

Prior to performing these procedures, install the EZ-SCREEN

LP per Section 3 of this document, including all other DIP switch

configuration settings (T/L, RR, and Scan Code). Align the E/R

pair and perform all required checkout procedures to ensure

proper operation. Ensure that the EZA-RBK-1 programming key

switch is rotated to the counter-clockwise position (Run position,

see Figure 7-11) at power-up and normal operation.

Important:

1. The first sensing beam (synchronization beam) at the display

end of the sensor must remain clear.

2. The number and location of blocked beams is indicated by the

receiver’s 7-segment display and the zone indicators. If the

configuration is reliable, this number should not change.

3. A reset switch (e.g., a normally open switch) must be used to

complete some programming procedures below.

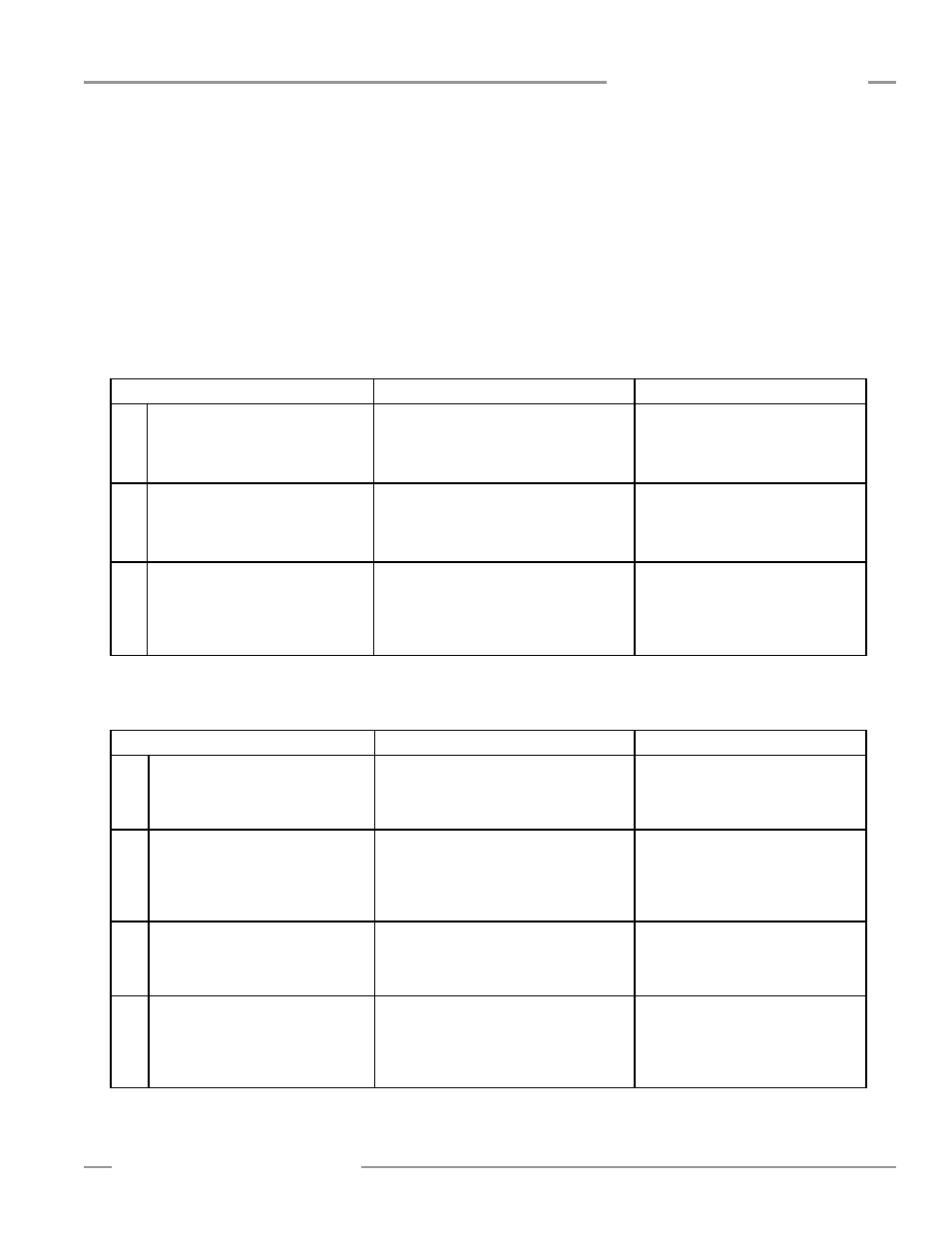

Initial programming ― no fixed blanking previously programmed, perform the following:

The following procedures must be completed within 10 minutes or a lockout will occur (Error Code 12 will be displayed).

Action

Indication

Comments

1

Locate the obstruction in the defined

area and secure it.

EZA-RBK-1: OFF

Receiver: number and location of blocked

beams is indicated by the 7-segment

display and the zone indicators.

If the configuration is reliable, this

number should not change.

2

Turn the programming key switch

to the Program position (clockwise)

momentarily (> ¼ second) and then

return to the Run position.

EZA-RBK-1: ON (key in Program position),

then slowly flashes for approximately

5 seconds (key returns to Run position).

Receiver: display indicates “P” “F” “C”

This “teaches” and saves the new

fixed blanking configuration.

3

Trip Output: the OSSDs turn ON.

Latch Output:After the EZA-RBK-1

indicator turns OFF, a valid reset

sequence is required to turn ON the

OSSDs

.

EZA-RBK-1: OFF

Receiver: display indicates normal

operation. (See Section 3.4.3, step 9.)

To change (relocate) or clear (remove) previous fixed blanking, perform the following steps:

The following procedures must be completed within 10 minutes or a lockout will occur (Error Code 12 will be displayed).

Action

Indication

Comments

1

Place the programming key switch in

the Program position (clockwise) until

step 3.

EZA-RBK-1: ON

Receiver: sequences between “P” “F” “A” and

the number of blocked beams

.

EZA-RBK-1 indicator steady ON

indicates program mode.

2

Locate or relocate the obstruction (e.g.

tooling, fixturing, etc.) in the defined

area and secure. If clearing the fixed

blanked area, remove all obstructions.

EZA-RBK-1: ON

Receiver: display sequences between “P” “F”

“A” and the number of blocked beams.

I

f an Error code 12 occurs

(programming time out), go to step #6

below (do not return the programming

key switch to the Run position at this

time).

3

Return the programming key switch to

the Run position (counter-clockwise)

.

EZA-RBK-1: slowly flashes, approximately 5

seconds

Receiver: display indicates “P” “F” “C”

This saves the new fixed blanking

configuration.

4

Trip Output: the OSSDs turn ON.

Latch Output: After the EZA-RBK-1

indicator turns OFF, a valid reset

sequence is required to turn ON the

OSSDs

.

EZA-RBK-1: OFF

Receiver: display indicates normal operation

if fixed blanking is removed. Otherwise, see

Section 3.4.3, step 9.