Overview, Installation and alignment, 3 machine primary control elements and edm inputs – Banner EZ-SCREEN Low-Profile Safety Light Curtain Systems User Manual

Page 39: Warning, External device monitoring

P/N 1334

37

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Overview

P/N 140044 rev.

E

37

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

EZ-SCREEN LP

Instruction Manual

Installation and Alignment

The principle of fault exclusion allows the designer to design

out the possibility of various failures and justify it through the

risk assessment process to meet the required level of safety

performance, such as the requirements of Category 2, 3 or 4.

See ISO 13849-1/-2 for further information.

External Device Monitoring

EZ-SCREEN LP provides three possible EDM configurations:

1-channel monitoring, 2-channel monitoring, and no monitoring.

Their functions are described below. The most common form

of EDM is 1-channel monitoring; its primary advantages are

simplicity of wiring and the ability to use the Auxiliary output.

The installation must prevent short circuits across the N.C.

monitoring contacts and to secondary sources of power.

Two-channel monitoring has the ability to detect additional

failures, such as short circuits, and should be used when those

failures can not be designed out or reasonably be excluded.

Two-channel monitoring is also the default setting and has the

advantage of additional diagnostic capability that can identify

which specific element that has slowed or failed.

3.5.3 Machine Primary Control Elements and EDM Inputs

A machine primary control element (MPCE) is an “electrically

powered element that directly controls the normal operation of

a machine in such a way that it is the last element (in time) to

function when machine operation is to be initiated or arrested”

(per IEC61496-1). Examples include motor contactors, clutch/

brakes, valves, and solenoids.

Depending on the level of risk of harm, it may be required to

provide redundant MPCEs or other control devices that are

capable of immediately stopping the dangerous machine motion,

irrespective of the state of the other. These two machine control

channels need not be identical (i.e., diverse redundant), but the

stop time performance of the machine (Ts, used to calculate the

safety distance, see Section 3.1.1) must take into account the

slower of the two channels. Refer to Figure 3-26 or consult the

machine manufacturer for additional information.

To ensure that an accumulation of failures does not compromise

the redundant control scheme (i.e., cause a failure to danger)

a method to verify the normal functioning of MPCEs or

other control devices is required. EZ-SCREEN LP provides

a convenient method for this verification: external device

monitoring (EDM).

For the EZ-SCREEN LP external device monitoring to function

properly, each device must include a normally closed (N.C.),

forced-guided (mechanically linked) contact that can accurately

reflect the status of the device. This ensures that the normally

open contacts, used for controlling hazardous motion, have a

positive relationship with the normally closed monitoring contacts

and can detect a failure to danger (e.g., contacts that welded

closed or stuck ON).

It is strongly recommended that a normally closed, forced-guided

monitoring contact of each FSD and MPCE be connected to

EDM inputs (see Figures 3-24 and 3-26). If this is done, proper

operation will be verified. Monitoring FSD and MPCE contacts is

one method of maintaining control reliability (OSHA/ANSI) and

Category 3 and 4 (ISO13849-1).

If monitoring contacts are not available or do not meet the

design requirement of being forced-guided (mechanically linked),

it is recommended to:

• Replace the devices so that they are capable of being

monitored,

or

• Incorporate the EDM function into the circuit as close to the

MPCE as possible (e.g., monitor the FSDs),

and

• Employ use of well-tried, tested, and robust components, and

generally accepted safety principles, including fault exclusion,

into the design and installation to either eliminate, or reduce

to an acceptable (minimal) level of risk, the possibility of

undetected faults or failures that can result in the loss of the

safety function.

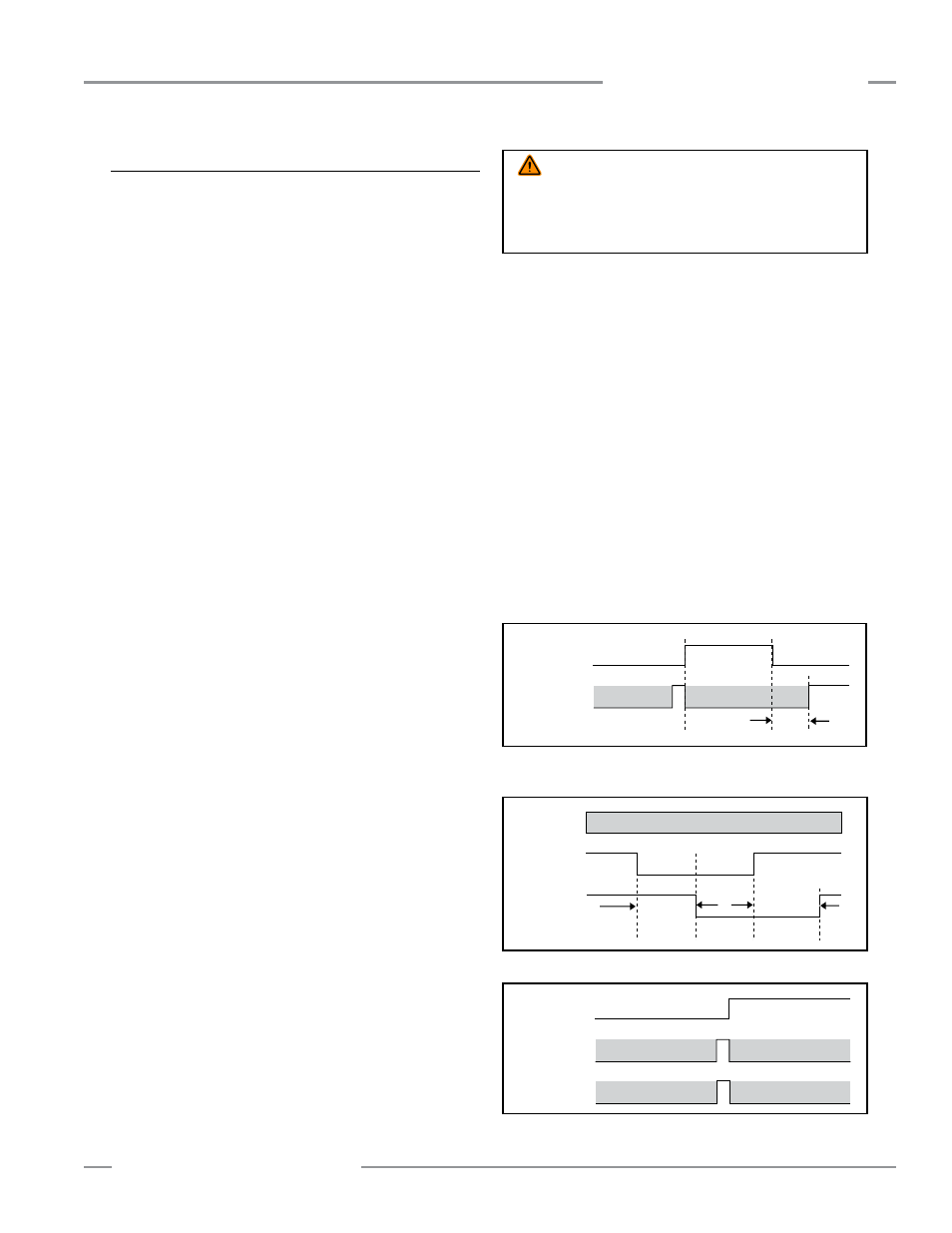

Safety Output

Closed

Open

OFF

ON

EDM

Don’t Care

Don’t Care

Don’t Care

Don’t Care

250 ms

Max.

250 ms

Max.

Safety Output

250 ms

Max.

250 ms

Max.

250 ms

Max.

250 ms

Max.

Don’t Care

Closed

Open

Closed

Open

EDM 1

EDM 2

Figure 3-19. One-channel EDM status, with respect to safety

output

Figure 3-20. Two-channel EDM, timing between channels

Figure 3-21. Two-channel EDM status, with respect to safety

output

Safety Output

Closed

Open

Closed

Open

OFF

ON

EDM 1

EDM 2

Must Match EDM 1

Must Match EDM 1

Must Match EDM 2

Must Match EDM 2

Must Match EDM 1

Must Match EDM 1

Must Match EDM 2

Must Match EDM 2

WARNING . . .

EDM Monitoring

If system is configured for “No Monitoring,” it is the user’s

responsibility to ensure that this does not create a hazardous

situation.