Overview, Introduction – Banner EZ-SCREEN Low-Profile Safety Light Curtain Systems User Manual

Page 3

P/N 133487

1

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Overview

P/N 140044 rev.

E

1

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

EZ-SCREEN LP

Instruction Manual

Overview

Electrical connections (power, ground, inputs and outputs)

are made via M12 (Euro-style) quick-disconnects or unique

RD (removable disconnect) cordsets, depending on model. A

“System” as referred to in this manual may be defined as an

emitter and its receiver, plus their cabling, or to a cascade of

emitters and their receivers and their cabling.

Functions such as Trip/Latch select, Display Invert, Cascading,

Fixed Blanking (including Remote Teach), Reduced Resolution

(Floating Blanking), Scan Code select, and External Device

Monitoring are described in Section 1.4. An auxiliary (aux.)

output may be used to signal the state of the OSSDs to a

process controller; see Section 1.4.3. All models require

a supply voltage of +24V dc ±15%. See Section 2.4 for

interfacing solutions.

Both emitter and receiver feature 7-segment Diagnostic

Displays and individual LEDs to provide continuous indication

of operating status, configuration and error conditions. See

Section 1.4.7 for more information.

This manual contains numerous WARNING and CAUTION

statements. Warnings refer to situations that could lead to

significant or serious personal injury or death. Cautions refer to

situations that could lead to slight personal injury or potential

damage to equipment.

1. Overview

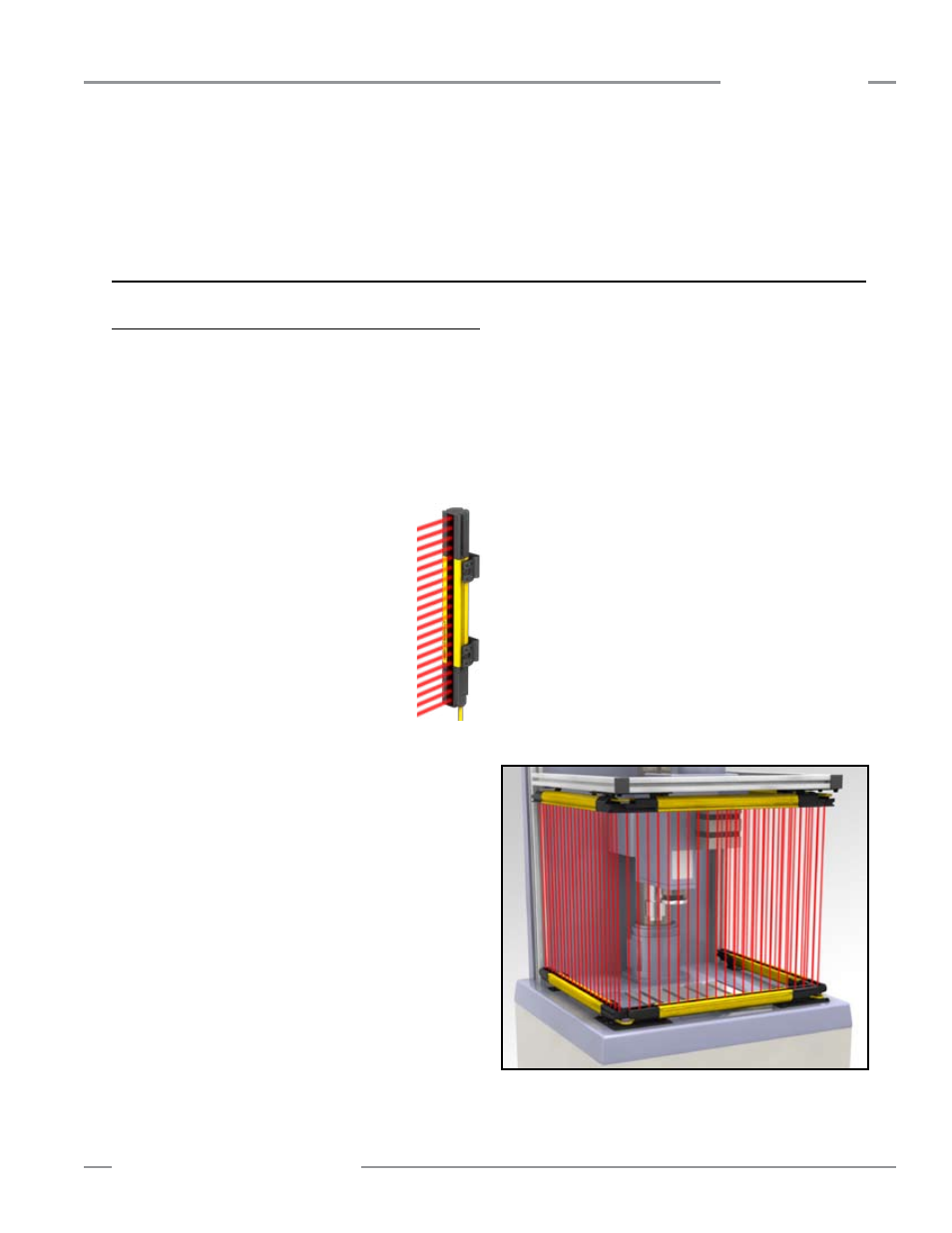

Figure 1-1. Banner EZ-SCREEN LP: a typical application

1.1

Introduction

Banner EZ-SCREEN LP emitters and receivers provide

a redundant, microprocessor-controlled, opposed-mode

optoelectronic “curtain of light,” or “safety light screen.”

EZ-SCREEN LP typically is used for point-of-operation

safeguarding, and is suited to safeguard a variety of machinery.

Emitters have a row of synchronized modulated infrared

(invisible) light-emitting diodes (LEDs) in a compact metal

housing. Receivers have a corresponding row of synchronized

photodetectors. The light screen created by the emitter and

receiver is called the “defined area”; its width

and height are determined by the length of the

sensor pair and the distance between them. The

low-profile housing provides maximum sensing

within minimum space; its defined area (sensing

area) is equivalent to the height of the housing.

The maximum sensing range is

7 m (23'), which

decreases if corner mirrors are used. The sensing

area extends from end to end of the housing; there

is no “dead zone.” Specialty brackets allow easy

mounting of cascaded sensors, without any loss of

resolution between sensor pairs.

In typical operation, if any part of an operator’s body (or any

opaque object) of more than a pre-determined cross section

is detected, the solid-state output signal switching device

(OSSD) safety outputs will turn OFF. These safety outputs are

connected to the guarded machine’s final switching devices

(FSDs) that control the primary control elements (MPCEs), which

immediately stop the motion of the guarded machine.

EZ-SCREEN LP is extensively FMEA (Failure Mode and Effects

Analysis) tested to establish an extremely high degree of

confidence that when properly installed, no system component

will (even if it should fail) cause a failure to danger.

The OSSD safety outputs are capable of performing a

“handshake” communication with the muteable safety stop

interface (MSSI) or universal safety stop interface (USSI) found

on other Banner Engineering safety products.

Banner EZ-SCREEN LP is a two-piece (“two-box”) system –

comprising an emitter and a receiver, but no external controller.

The external device monitoring (EDM) function ensures the

fault detection capability required by U.S. Control Reliability and

ISO13849-1 Categories 3 and 4 without a third box, a controller

or a “smart” (i.e., self-checking) safety module required of

systems without EDM.