Overview, Installation and alignment, 6 adjacent reflective surfaces – Banner EZ-SCREEN Low-Profile Safety Light Curtain Systems User Manual

Page 27: Warning

P/N 133487

25

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Overview

P/N 140044 rev.

E

25

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

EZ-SCREEN LP

Instruction Manual

Installation and Alignment

d

d

d

Operating Range

(R)

Emitter

Receiver

Do not position reflective surfaces

within the shaded area

top view

side view

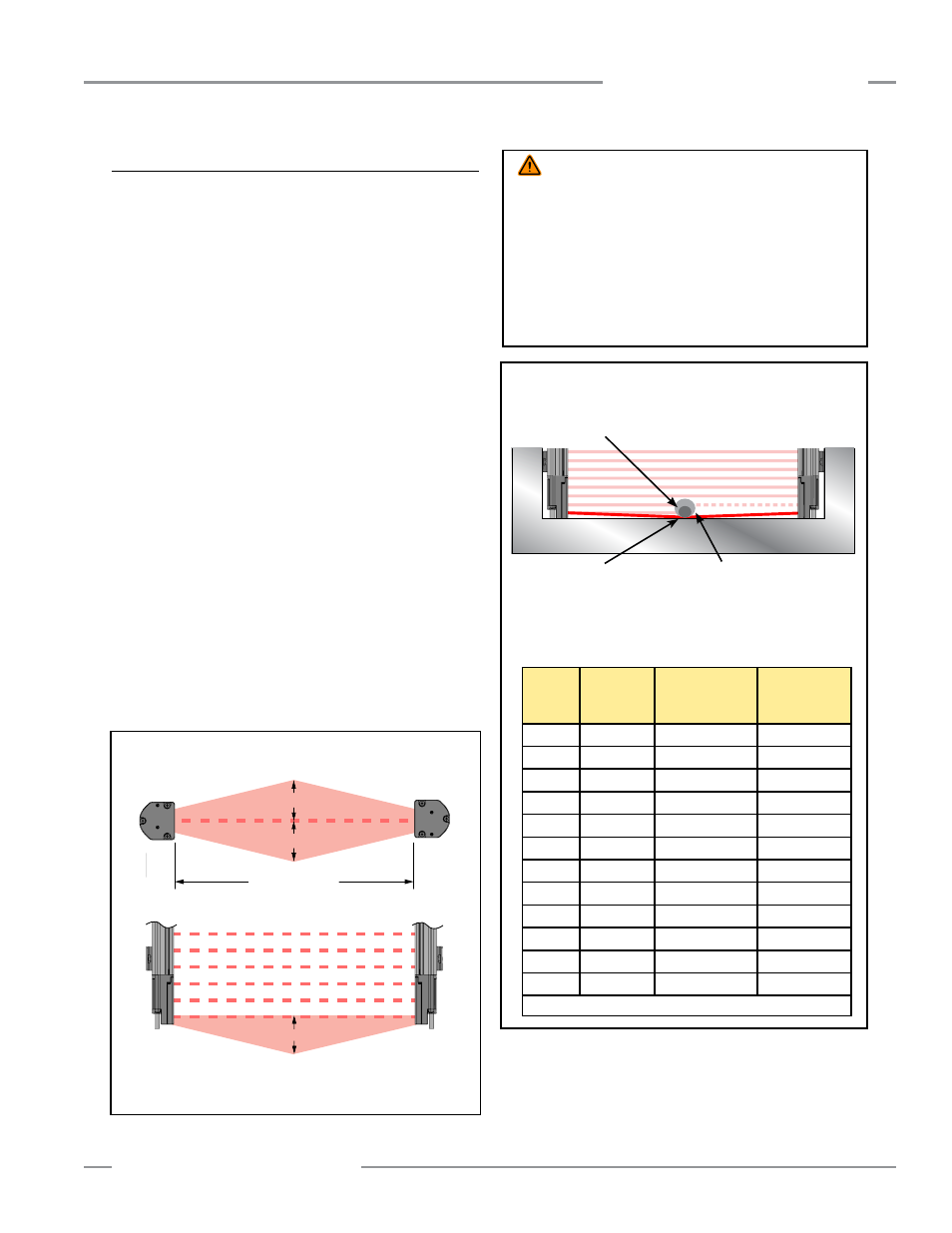

Figure 3-6. Adjacent reflective surfaces

3.1.6 Adjacent Reflective Surfaces

A reflective surface adjacent to the defined area may deflect

one or more beams around an object in the defined area. In

the worst case, an “optical short circuit” may occur, allowing an

object to pass undetected through the defined area (see Figure

3-6).

This reflective surface may result from shiny surfaces or glossy

paint on the machine, the workpiece, the work surface, the floor

or the walls. Discover beams deflected by reflective surfaces by

performing the trip test portion of the final alignment procedure

and the periodic checkout procedures (Section 3.4.4).

To eliminate problem reflections:

• If possible, relocate the sensors to move the beams away

from the reflective surface(s), being careful to maintain

adequate safety (minimum) distance (see Figure 3-6).

• Otherwise, paint, mask or roughen the shiny surface to

reduce its reflectivity.

• Where these are not possible (as with a shiny workpiece or

machine frame), determine the worst-case resolution resulting

from the optical short circuit and use the corresponding depth

penetration factor (Dpf) in the safety (minimum) distance formula

(see Figure 3-7 and Section 3.1.1); or mount the sensors in

such a way that the receiver’s field of view and/or the emitter’s

spread of light are restricted from the reflective surface.

• Repeat the trip test to verify that the changes eliminated

the problem. If the workpiece is especially reflective and

comes close to the defined area, perform the trip test with the

workpiece in place.

Use the table below to calculate Dpf or Factor “C” when a shiny surface

causes an optical short circuit.

Test

Piece

Model

Resolution

Depth Penetration

Factor for U.S.

Applications

Factor “C”

for European

Applications

STP-13

14 mm

24 mm (1")

0 mm

STP-2

19 mm

41 mm (1.6")

40 mm (1.6")

STP-16

25 mm

61 mm (2.5")

88 mm (3.5")

STP-14

30 mm

78 mm (3")

128 mm (5")

STP-4

32 mm

85 mm (3.3")

144 mm (5.7")

STP-17

34 mm

92 mm (3.6")

160 mm (6.3")

STP-1

38 mm

106 mm (4.2")

192 mm (7.6")

STP-3

45 mm

129 mm (5")

850 mm (33.5")

STP-8

51 mm

150 mm (5.9")

850 mm (33.5")

STP-5

58 mm

173 mm (6.8")

850 mm (33.5")

STP-15

60 mm

180 mm (7")

850 mm (33.5")

STP-12

62 mm

187 mm (7.4")

850 mm (33.5")

See Section 3.1.1 for Safety (Separation) Distance calculation information

Figure 3-7. Increasing resolution value to mitigate an optical short

circuit

Optical Short

Circuit

Increasing the size of the test piece to

block additional beams will cause a blocked

condition. The size of the test piece required

to do this will determine the actual resolution.

Reflective Surface

At the midpoint of the defined area, a test piece (represented by the

darker circle) with the specified system resolution does not cause

a blocked condition, due to an optical short circuit. Zone indicator

LEDs are ON Green and the OSSDs are ON.

WARNING . . .

Avoid Installation Near

Reflective Surfaces

Avoid locating the defined area near a reflective surface; it could

reflect sensing beam(s) around an object or person within the

defined area, and prevent its detection by the EZ-SCREEN LP

System. Perform the trip test, as described in Section 3.4.4, to

detect such reflection(s) and the resultant optical short circuit.

Failure to prevent reflection problems will result in incomplete

guarding and could result in serious bodily injury or death.

Emitter

Receiver

Do not position reflective surfaces within the shaded area

Operating Range

(R)

At installed operating range (R): d = 0.0437 × R (m or ft)

Operating range 0.1 to 3 m (4" to 10'): d = 0.13 m (5")

Operating range > 3 m ( > 10'):

d = 0.0437 × R (m or ft)