Overview, Troubleshooting and maintenance, 2 emitter error codes – Banner EZ-SCREEN Low-Profile Safety Light Curtain Systems User Manual

Page 53: 2 test mode

P/N 133487

51

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com

•

Tel: 763.544.3164

Overview

P/N 140044 rev. E

51

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com

•

Tel: 763.544.3164

EZ-SCREEN LP

Instruction Manual

Troubleshooting and Maintenance

5.1.2 Emitter Error Codes

Multiple-digit codes are sequential, followed by a pause.

Diagnostic

Display*

Error Description

Cause of Error and Appropriate Action

Emitter Error

This error can occur either due to

excessive electrical noise or due to an

internal failure.

•

Reset the emitter by either performing a reset or cycling power to the emitter (see

Section 4.3).

• If the error clears, perform the daily checkout procedure (Section 6.3) and if OK,

resume operation.

If the System fails the daily checkout procedure, replace the emitter.

• If the error continues, check the ground connection (see Section 2.3).

•

If the sensor has a good earth ground connection, check for electrical noise (see

Section 5.3).

• If the error continues, replace the emitter.

Excessive Noise Error

This error can occur due to excessive

electrical noise.

•

Reset the emitter by either performing a reset or cycling power to the emitter (see

Section 4.3).

•

If the error clears, perform the daily checkout procedure (Section 6.3) and if OK,

resume operation.

If the System fails the daily checkout procedure, replace the emitter.

• If the error continues, check the ground connection (see Section 2.3).

•

If the sensor has a good earth ground connection, check for electrical noise (see

Section 5.3).

• If the error continues, replace the emitter.

“Axx”/“cxx”,

where “xx” are

alpha-numeric

characters

Advanced Diagnostics for the purpose

of factory troubleshooting and repair;

not intended for field troubleshooting.

If advanced diagnostic codes are inadvertently displayed, toggle the Invert Display

DIP switch (to the opposite state and back, within 1 second) to return to the standard

error code display.

This indication can occur due to a potential problem with an LED and is provided

as an early warning indicator

•

Emitter LED Problem

This is NOT an error.

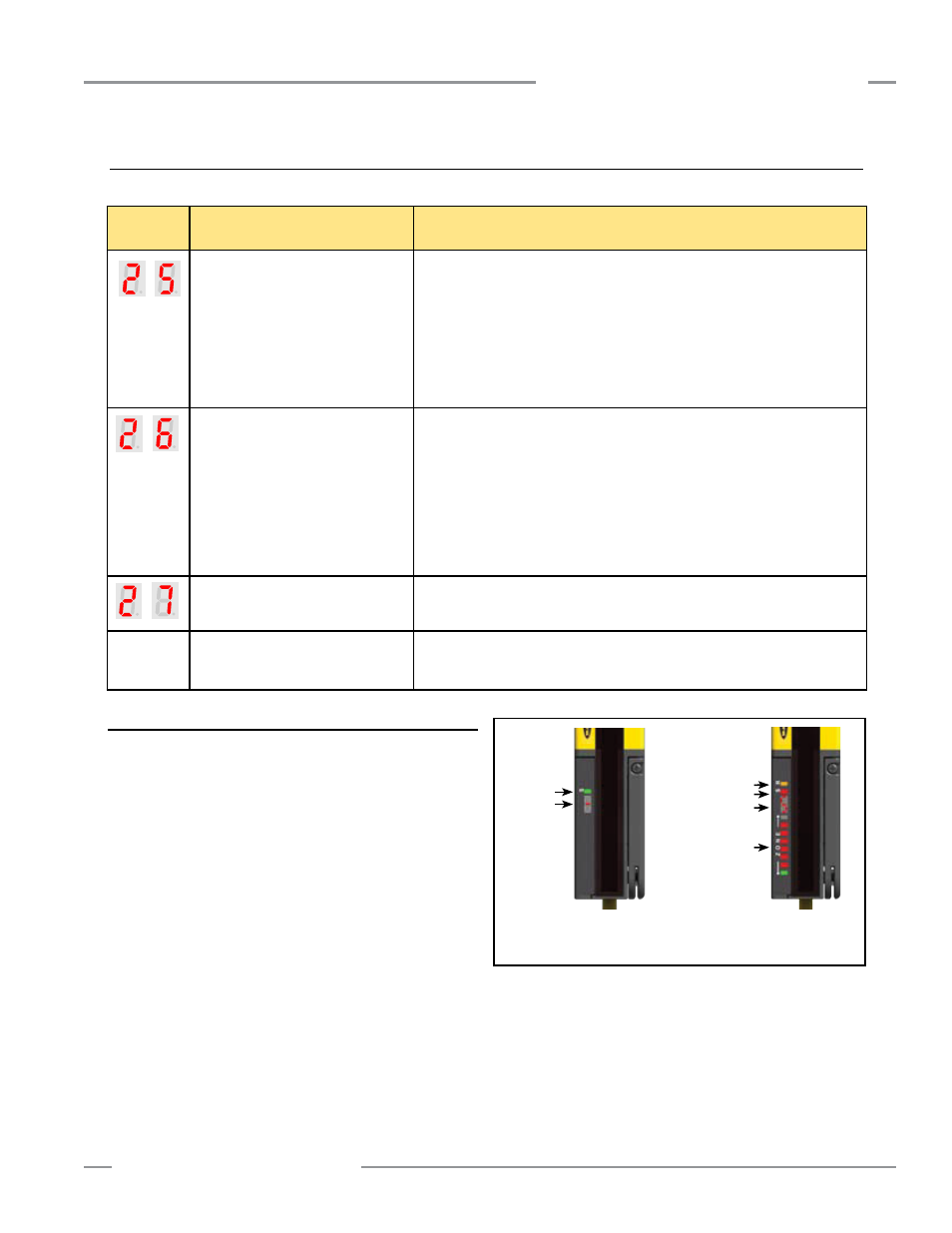

5.2 Test Mode

If System will not align or go to a Green/Clear condition, the

emitter’s Test input may be open. If so, the receiver Reset

indicator will be Yellow, all Zone indicators Red, and the Status

LED Red; the 7-segment display will show a numerical value

equal to the total number of beams, minus one. (Multiple-digit

codes are displayed sequentially.) For example, if an array has

55 beams total, the display would indicate 54. The emitter’s

Status indicator will flash Green. See Section 4.4 and Figure 5-1.

(Exception: on a 14-beam system only, the Zone 1 indicator will

be Green, and all others Red.)

Figure 5-1. TEST mode status indicators

* The 7-segment display will sequentially show a numerical value equal to one

less than the total number of beams. For example, if an array has 55 beams total,

the display would indicate 54.

Receiver

Emitter

All Red (except for

14-beam systems,

where Zone 1

indicator will be

Green)

Dash

Flashing

Green

Total number of

beams (less one)*

Yellow

Red