9 internal dosing unit internal dosing unit – Metrohm 784 KFP Titrino User Manual

Page 111

4.2 Diagnosis

784 KFP Titrino

108

9 Internal dosing unit

Internal dosing unit

•

Remove exchange unit.

•

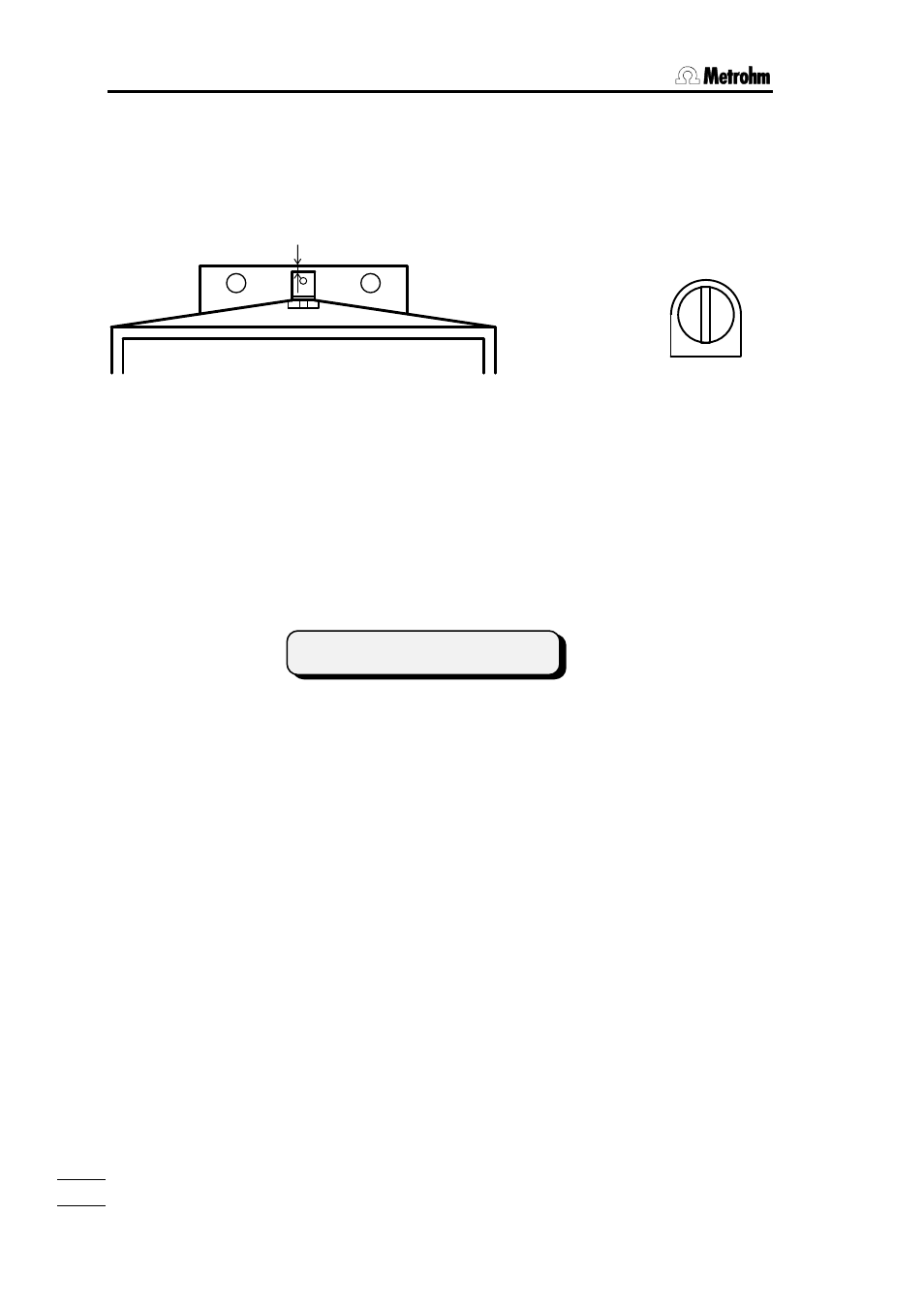

Check spindle zero position, see Fig. 5.

0.2 - 0.6 mm

Fig. 5

Fig. 6

The spindle must be 0.2 – 0.6 mm below the edge of the sliding plate.

The bar of the stopcock coupling must be exactly parallel to the lateral edges of the

KFP Titrino, see Fig.6.

•

Reinsert Exchange Unit.

Titrino fills.

The display of before reappears.

•

Knob

'dV/dt' to right stop.

•

Press the

time measure the time from start to end.

XXX X

********

cylinder empty !

mind selected language!

Spindle remains at maximum position. The transit time of the spindle is

20 s.

•

Measure spindle lifting (can be performed only if the 3.496.0070 Dummy Exchange Unit is

inserted or the locking switch (in right hole) is carefully operated with a screwdriver after re-

moval of the Exchange Unit).

From the start point, the spindle travels 80 mm. Instead of the spindle height, the ex-

pelled volume can be measured (corresponds to max. vol. of Exchange Unit used).

•

Press

again in the 'ready' position.

Times for filling:

per stop cock cycle 1 s

for filling

20 s (Tolerance: 10 %)

The following generally holds: Spindle and stopcock must move at a constant speed

(noise!). In the filling setting, the stopcock coupling must position the lever of the Ex-

change Unit correctly at the left stop (with virtually no play and without sticking).

•

Set potentiometer

'dV/dt' to left stop.

•

Press

(on instrument) at same time and use a stopwatch to measure the time for

1/10 of the cylinder volume to be expelled. The time should be ca. 90...110 s.

•

Set potentiometer 'dV/dt' to right stop.

•

Press