Troubleshooting – Rockwell Automation LDAT Integrated Linear Thrusters User Manual

Page 55

LDAT-Series Integrated Linear Thrusters 55

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Troubleshooting

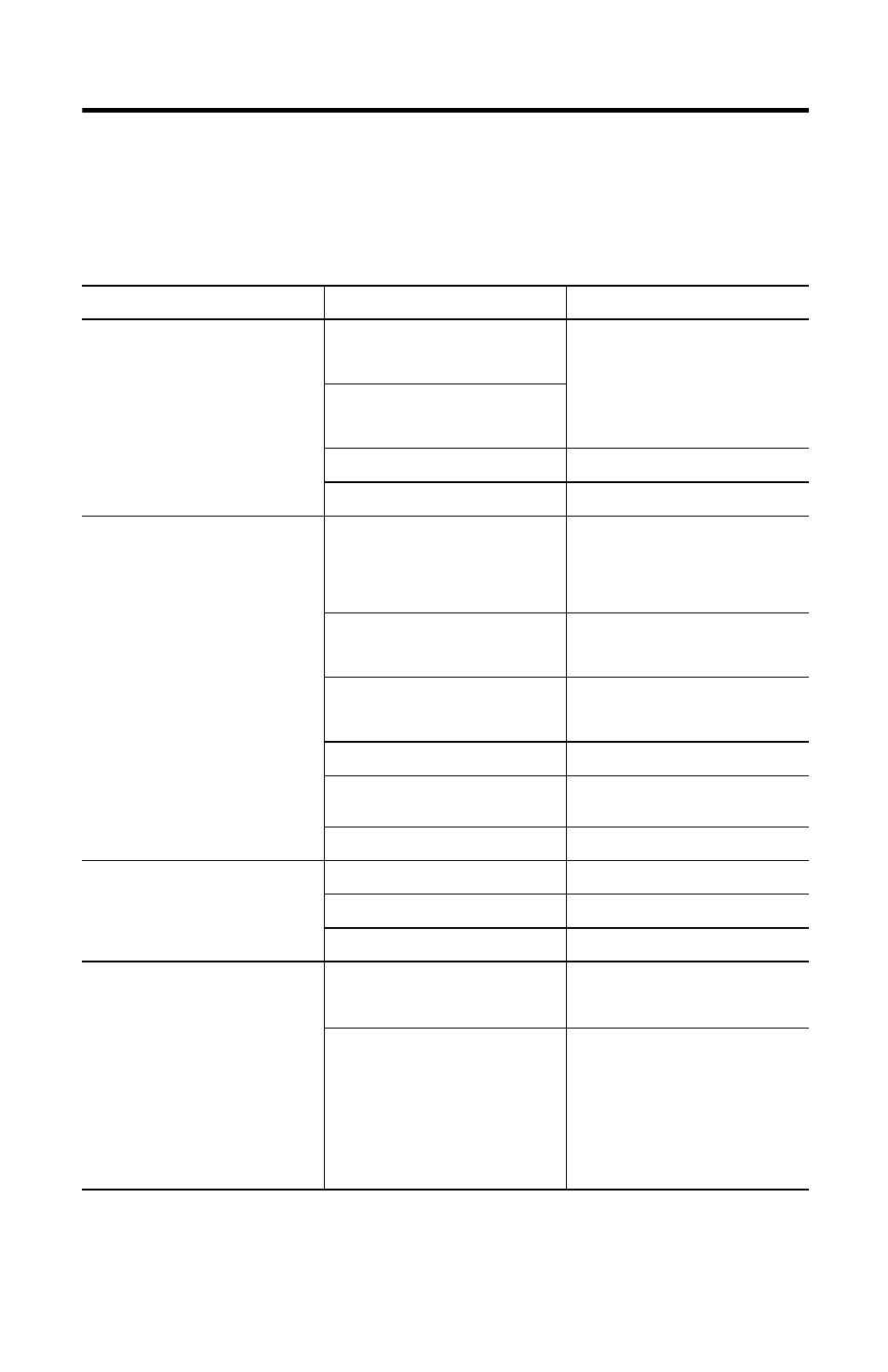

Use this table to troubleshoot your linear thruster.

Troubleshooting Linear Thrusters

Description

Possible Cause

Corrective Action

Noises or vibrations

Linear thruster mounting is not fastened

properly.

Verify correct mounting and torques

Load or mounting accessory fixture is not

fastened properly.

Linear thruster not tuned

Tune linear thruster

Bearing wear

Replace bearings

Excess slider friction or rubbing

Linear thruster is not mounted to a flat

rigid surface per mounting guidelines.

Review mounting guidelines

Improper fastening of mounting feet

accessories.

Review mounting instructions.

Metal debris or hardware on magnet

surface of slider.

Remove debris.

Debris on strip cover

Clean strip cover

Debris or loose hardware on slider

bearings

Remove debris from using masking tape

Bearing wear

Replace bearings

No response from linear thruster

Controller or drive not enabled

Enable controller and drive

Controller or drive faulted

Reset the controller or drive

Improper or failed wiring

Verify correct wiring

Linear thruster is enabled but operating

erratically or not at all.

Motor Feedback Cable connection may

be faulty or intermittent

Run Hookup Test, verify wiring

Encoder magnetic strip is damaged

Verify function of linear encoder over full

range of travel. If a particular location is

malfunctioning, replace incremental

encoder magnetic scale.

If using an absolute encoder, return for

repair.