Rockwell Automation LDAT Integrated Linear Thrusters User Manual

Page 13

LDAT-Series Integrated Linear Thrusters 13

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Follow these steps to prepare the linear thruster for installation on the machine.

1.

Provide sufficient clearances in the area of the linear thruster for it to stay within its

specified operating temperature range.

Refer to

for the operating temperature range. Do not enclose

the linear thruster unless forced air is blown across the linear thruster for cooling. Keep

other heat producing devices away from the linear thruster.

2.

Make sure the mounting surface supports the linear thruster evenly so that it is free of

mechanical stress and distortion. Evenness of the mounting surface must be within

0.127 mm (0.005 in.).

3.

Attach mounting accessories, shown on

page 57

, to the linear thruster.

4.

Attach slider-end accessories, see on

page 58

, to the work load as outlined below.

Be sure the work load center of gravity is centric to the slider.

Use these torque values to attach a rod eye, rod clevis or payload bracket to the slider.

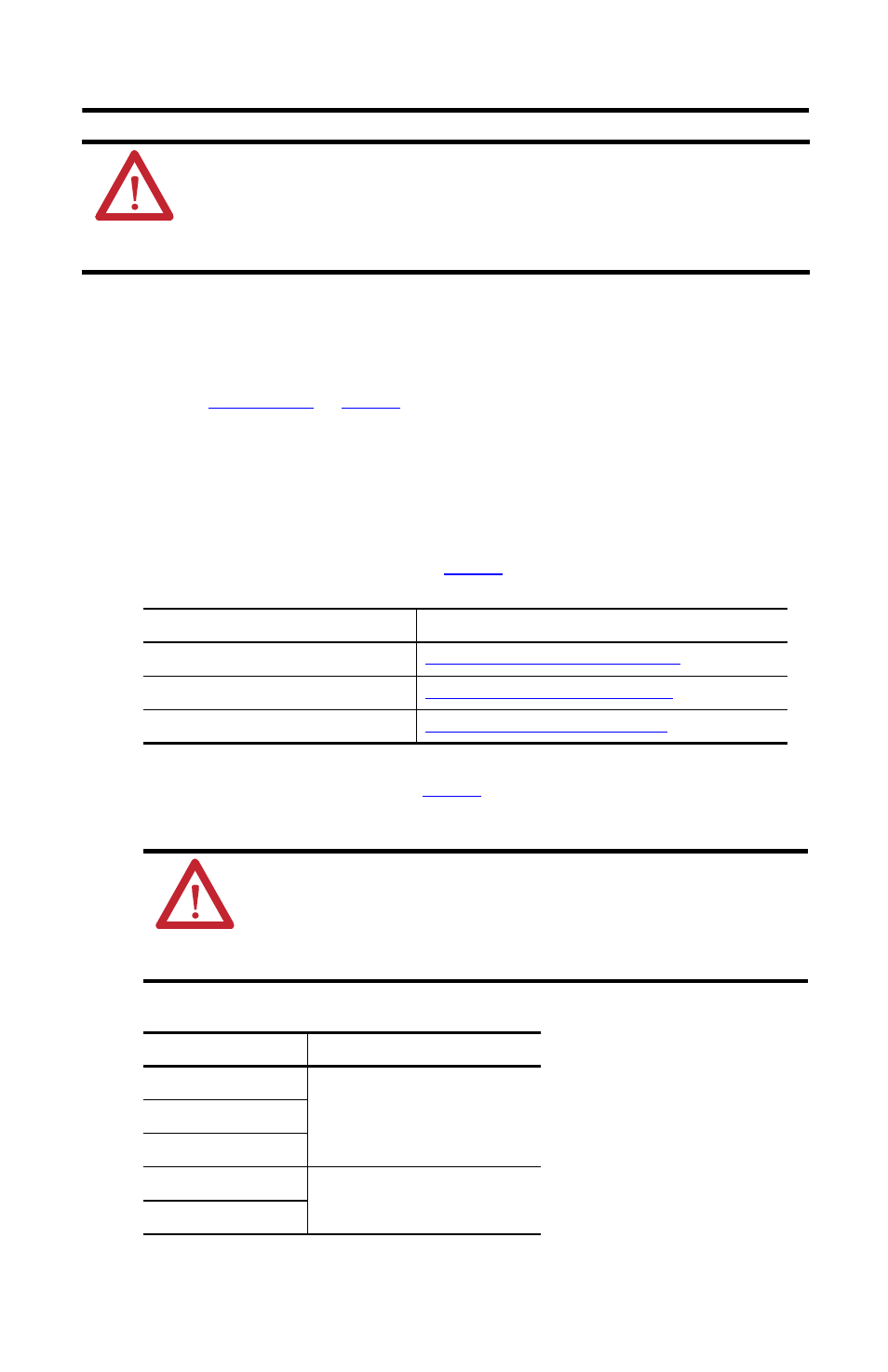

ATTENTION: Unmounted linear thrusters, disconnected mechanical couplings, and disconnected

cables are dangerous if power is applied.

Appropriately identify (tag-out) disassembled equipment, and restrict (lock-out) access to

electrical power.

Failure to observe these safety precautions could result in personal injury.

If you are installing with this accessory

Refer to this table or procedure

Clevis mount

Install with Clevis Mount Accessory on page 16

Foot mount

Install with Foot Mount Accessory on page 16

None

Direct Mount the Linear Thruster on page 17

ATTENTION: Damage may occur to the linear thruster bearings and the feedback device

if sharp impact to the slider is applied during installation. Do not strike the slider with

tools during installation or removal.

Failure to observe these safety precautions could result in damage to the linear thruster

and its components.

Cat. No.

Torque, max

(1)

(1)

Unless otherwise noted, torque specifications have a ±20% tolerance.

LDAT-S03

6.8 N•m (5 lb•ft)

LDAT-S05

LDAT-S07

LDAT-S10

14.7 N•m (10.83 lb•ft)

LDAT-S15