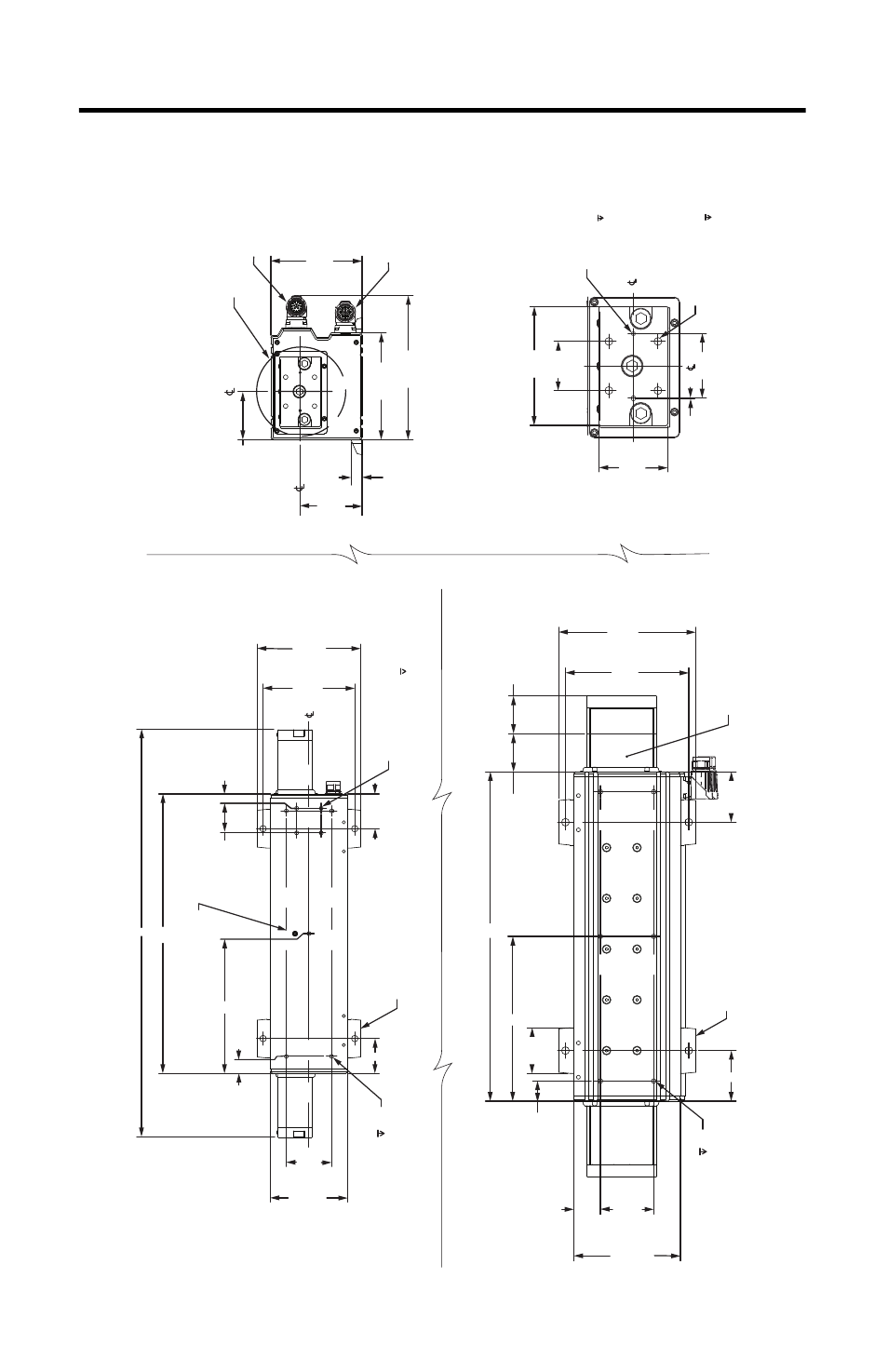

Linear thrust er d imensions (frame 50 and 75) – Rockwell Automation LDAT Integrated Linear Thrusters User Manual

Page 22

22 LDAT-Series Integrated Linear Thrusters

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

1/2 str

ok

e

Ty

pical both ends

(1)

B

26.35

(1.04)

Typical

A

140.00

(5.51)

120.00

(4.72)

60.00

(2.36)

Typical

Ty

pical

14.56

(0.57)

70.00

(2.76)

35.00 (1.38)

M

162.00

(6.38)

180.00

(7.09)

189.03

(7.44)

Shipping/

Handling L

ockscr

ew

L

63.00

(2.48)

81.49

(3.21)

66.35

(2.612)

140.00

(5.51)

Refer

enc

e

To

St

op

Typical both ends

(1)

49.53

(1.95)

D

etail A

Slider end moun

ting

ty

pical both ends

AT

TENTION:

High magnetic field

.

Us

e caution with t

ools and loose har

dw

ar

e.

Pa

cemak

er w

ear

ers: main

tain

300 mm (12 in.) distanc

e.

38.00

(1.50)

Squar

e

53.00

(2.09)

50.00

(1.97)

1.00

(0.04)

92.00

(3.62)

Moun

ting Holes

(4X) M6 x 1.0-6H x 9.0

D

ow

el P

in Clear

anc

e

(2X) M3 x 6.0 [.24]

A

70.00

(2.76)

160.00

(6.30)

142.00

(5.59)

C

38.00

(1.50)

Squar

e

26.35

(1.04)

Typical

22.35

(0.88)

M

53.85

(2.120)

120.00

(4.72)

Refer

enc

e

O

ptional Clevis Moun

ting Holes

(4X) M6 x 1.0-6H x 7.0 (.35)

(1)

Up

to

appr

ox

ima

tely

5

m

m

(0.2

in.)

ov

er

tr

av

el

at

each

end

.A

n

additional

12.7

mm

(0.5

in.)

ov

er

tr

av

el

each

end

when

st

op

is

fully

compr

essed

in

a

cr

ash

co

ndition.

LD

AT

-MID

-FTMOUNT optional foot

moun

ting uses (4X) M8 x 1.25 x 20, min

sock

et head cap scr

ews

.

LD

AT

-MID

-FTMOUNT optional foot

moun

ting uses (4X) M8 x 1.25 x 20, min

sock

et head cap scr

ews

.

Po

w

er and feedback

connec

to

rs can r

ota

te

180°.

Fe

edback C

onnec

to

r

P

ow

er C

onnec

to

r

See

D

etail A

M6 x 1.0-6h x 7.0

Moun

ting Holes in N plac

es

.

M6 x 1.0-6h x 7.0

Moun

ting Holes in N plac

es

.

Bott

om

Vi

ew of S

ide Mounting

Bott

om

Vi

ew of Bott

om Mounting

End

Vi

ew of Bott

om Mounting

Linear

Thrust

er D

imensions (frame

50 and

75)