Bearing lubrication – Rockwell Automation LDAT Integrated Linear Thrusters User Manual

Page 53

LDAT-Series Integrated Linear Thrusters 53

Rockwell Automation Publication LDAT-IN001A-EN-P - August 2012

Bearing Lubrication

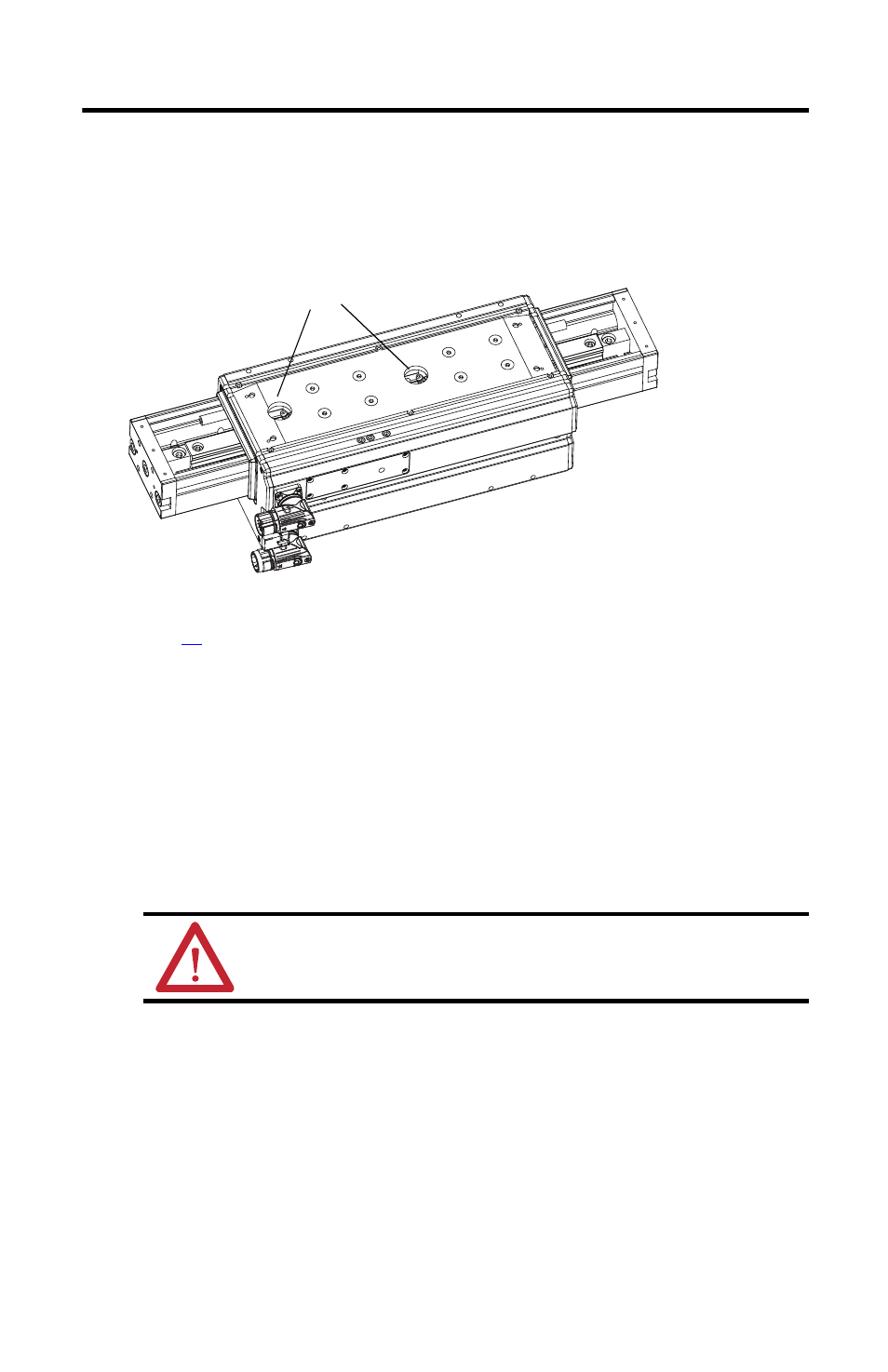

Lubricate the linear thruster bearings as shown and described below.

Use the MP-Series™ Integrated Linear Stage grease pump kit, (catalog number MPAS-GPUMP),

and additional grease cartridges as necessary.

1.

If your linear thruster has the strip cover option, remove it by following the procedure on

page

2.

Clean grease from the bearing by using clean lint free cloth and isopropyl alcohol.

3.

Place the grease pump on the grease fitting just inside the stator housing, pushing in until

firm contact with the grease fitting is made.

4.

Pump the handle until back pressure is felt, or a maximum of two strokes is made.

5.

Repeat steps 1 and 3 on all grease fittings.

If your linear thruster has a strip cover install it by following the next steps.

6.

Carefully slide the slider cover the through the plastic end-caps centering it on the linear

thruster.

7.

Clean all screws and apply fresh Loctite 242 to them.

8.

Install the end clamps with the M3 x 0.5 x 6 mm button head cap screws.

9.

Install the stator cover with the M3 x 0.5 x 6 mm flat head cap screws.

10.

Torque all screws to 1.1 N•m (10 lb•in).

ATTENTION: The slider cover has sharp edges. Use care when handling.

Lubrication Access

LDAT-Series Integrated Linear Thruster

(LDAT-S73010x-xxS is shown with strip cover removed)