General system anomalies – Rockwell Automation MDF-SB1304F Kinetix 6000M Integrated Drive-Motor System User Manual

Page 92

92

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Chapter 7

Troubleshooting the Kinetix 6000M System

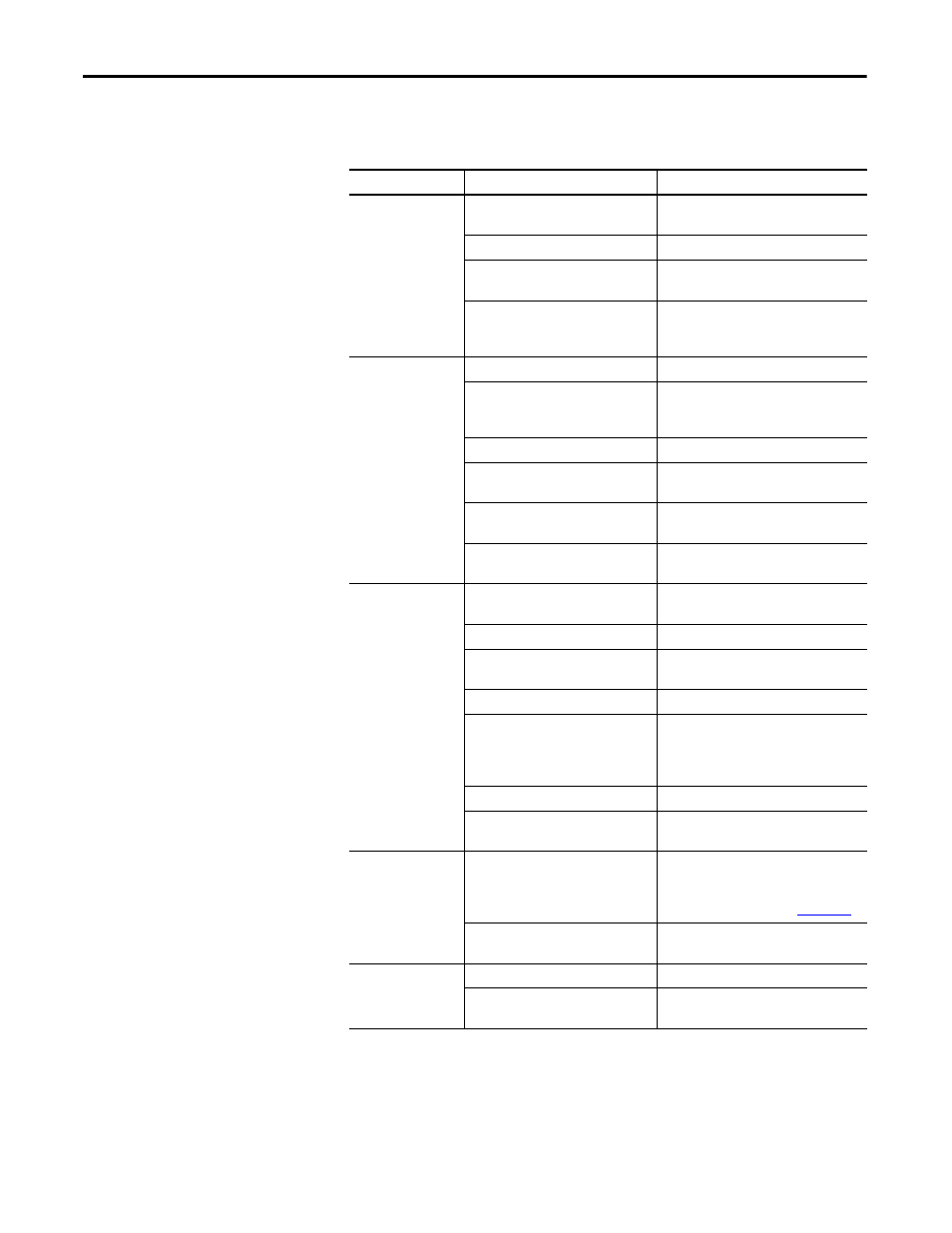

General System Anomalies

These anomalies do not always result in a fault code, but may require

troubleshooting to improve performance.

Condition

Potential Cause

Possible Solution

Axis or system is

unstable.

Unintentionally in Torque mode.

Check to see what primary operation mode

was programmed.

IDM unit tuning limits are set too high.

Run Tune in RSLogix 5000 software.

Position loop gain or position controller

accel/decel rate is improperly set.

Run Tune in RSLogix 5000 software.

Mechanical resonance.

Notch filter or output filter may be required

(refer to Axis Properties dialog box, Output tab

in RSLogix 5000 software).

You cannot obtain the

acceleration/

deceleration that you

want.

Torque Limit limits are set too low.

Verify that current limits are set properly.

The system inertia is excessive.

• Check IDM unit size versus application

need.

• Review servo system sizing.

The system friction torque is excessive.

Check IDM unit size versus application need.

Available current is insufficient to supply

the correct accel/decel rate.

• Check IDM size versus application need.

• Review servo system sizing.

Acceleration limit is incorrect.

Verify limit settings and correct them, as

necessary.

Velocity Limit limits are incorrect.

Verify limit settings and correct them, as

necessary.

IDM unit does not

respond to a velocity

command.

The axis cannot be enabled for 1.5

seconds after disabling.

Disable the axis, wait for 1.5 seconds, and

enable the axis.

The IDM wiring is open.

Replace the IDM unit.

The IDM thermal switch has tripped.

• Check for a fault.

• Check the wiring.

The IDM unit has malfunctioned.

Replace the IDM unit.

The coupling between IDM unit and

machine has broken (for example, the IDM

unit moves, but the load/machine does

not).

Check and correct the mechanics.

Primary operation mode is set incorrectly.

Check and properly set the limit.

Velocity or current limits are set

incorrectly.

Check and properly set the limits.

Presence of noise on

wires/cables.

Recommended grounding per installation

instructions have not been followed.

• Verify grounding.

• Route wire away from noise sources.

• Refer to System Design for Control of

Electrical Noise, publication

Line frequency may be present.

• Verify grounding.

• Route wire away from noise sources.

Sercos ring not phasing

up.

Duplicate node settings.

Change the node address.

Incompatible data rates.

Verify that the data rate is set to 8 Mbps for all

Kinetix 6000 modules.