Example heat dissipation calculation – Rockwell Automation 1747-L5xx SLC 500 Modular Hardware Style User Manual User Manual

Page 267

Publication 1747-UM011G-EN-P - June 2008

Calculating Heat Dissipation for the SLC 500 Control System 267

Example Heat Dissipation

Calculation

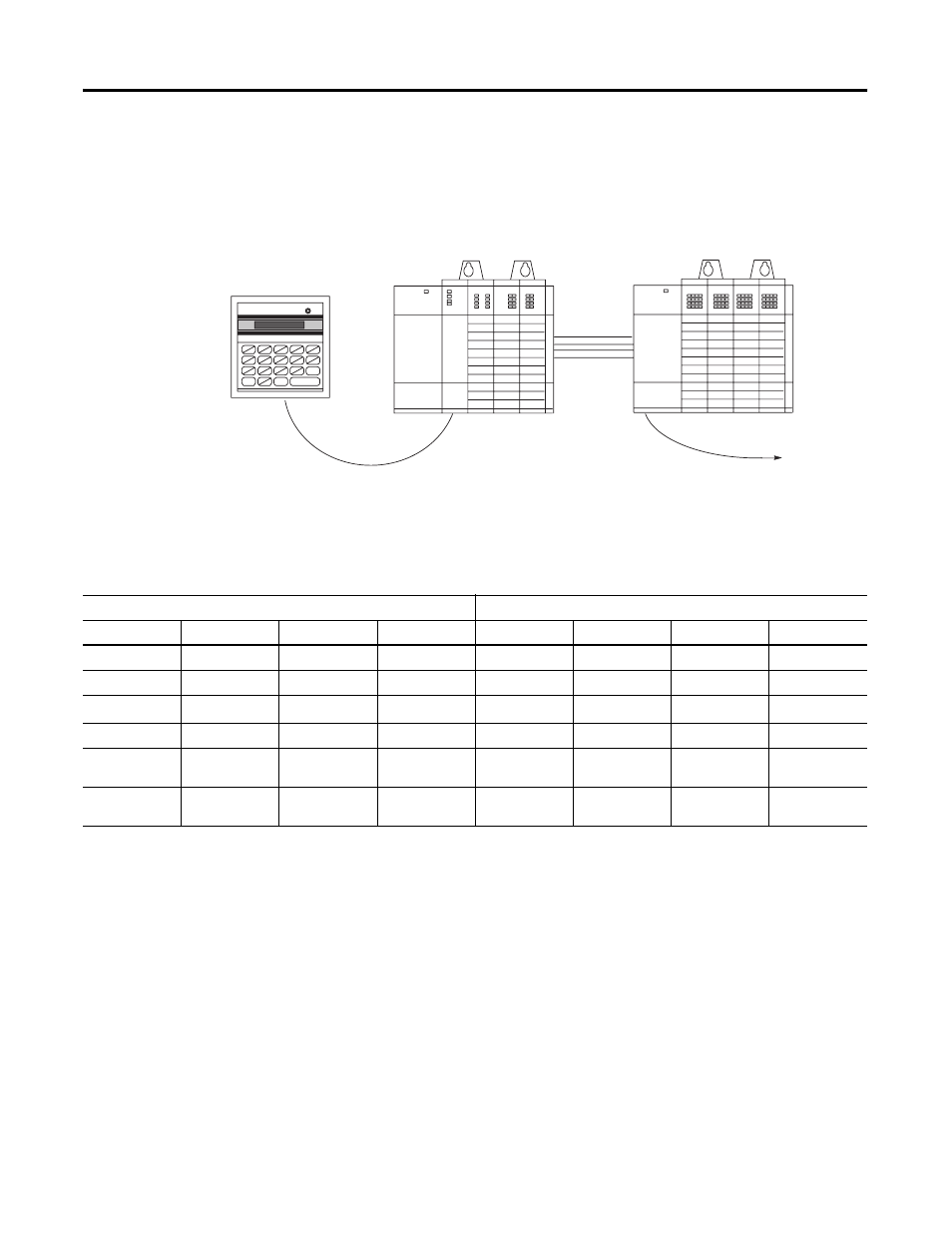

If your controller consisted of the following hardware components,

you would calculate heat dissipation as shown in the worksheet on

page 268.

The following table details the total watts dissipated by the modules

and peripheral devices in the above SLC 500 controller. The numbers

were taken from the tables on page 263.

Chassis 2

Chassis 1

DTAM

Peripheral Device

User Power to

Peripheral

Slot

Slot

0

1

2

3

5

6

7

4

Chassis 1

Chassis 2

Slot Number

Cat. No.

Min Watts

Max Watts

Slot Number

Cat. No.

Min Watts

Max Watts

0

1747-L511

1.75

1.75

4

1746-IA16

0.425

4.800

1

1746-BAS

3.750

3.80

5

1746-IA16

0.425

4.800

2

1746-IA8

0.250

2.40

6

1746-OW16

5.170

5.500

(2)

3

1746-OV8

0.675

6.90

7

1746-OW16

5.170

5.700

Peripheral

Device

1747-DTAM

2.500

2.50

NA

NA

NA

NA

User Power to

Peripheral

NA

NA

NA

NA

NA

2.400

(1)

NA

(1)

The user power on the 1746-P1 power supply for chassis 2 is being used to power a peripheral (100 mA at 24V dc).

(2)

This output card uses 5.5 W because only 10 points are on at any one time. Using the calculated watts formula - (number of points energized x watts per point) + minimum

watts = heat dissipation of module - the calculated watts for the 1746-OW16 module is 5.5 W: (10 points x.33) + 5.17 = 5.5 W.