Fiber optic cable routing – Rockwell Automation 1395 ControlNet Communication Board User Manual

Page 62

4–8

Installation

Publication 1395.5.37 – March, 1999

Fiber Optic Cable Routing

Special care should be taken when mounting and routing fiber optic

cable to prevent damage that could degrade signal transmission.

–

You must maintain a minimum bend radius of 1 inch at all times.

If you cannot maintain this bend radius due to cabinet constraints,

remove the plastic strain relief as shown in Figure 4.4 to allow

you to maintain the bend radius at 1”.

If the strain relief is removed, connect the cable with the blue

connector to the dark gray connection on the board. Connect the

cable with the black connector to the light gray connection on the

board. The cable with the blue connector is the receive (RX)

cable, and the cable with the black connector is the transmit (TX)

cable.

–

If the strain relief is removed from the cable assembly, the cable

weight may need to be be supported to prevent the connectors

from unplugging in some applications. If your application has a

long cable droop, or an unsupported wire bundle, use a zip tie to

support the excess weight.

–

If a cable is kinked or nicked during installation, it MUST be

replaced. A kinked or damaged cable greatly reduces signal

strength and could cause the drive to fault.

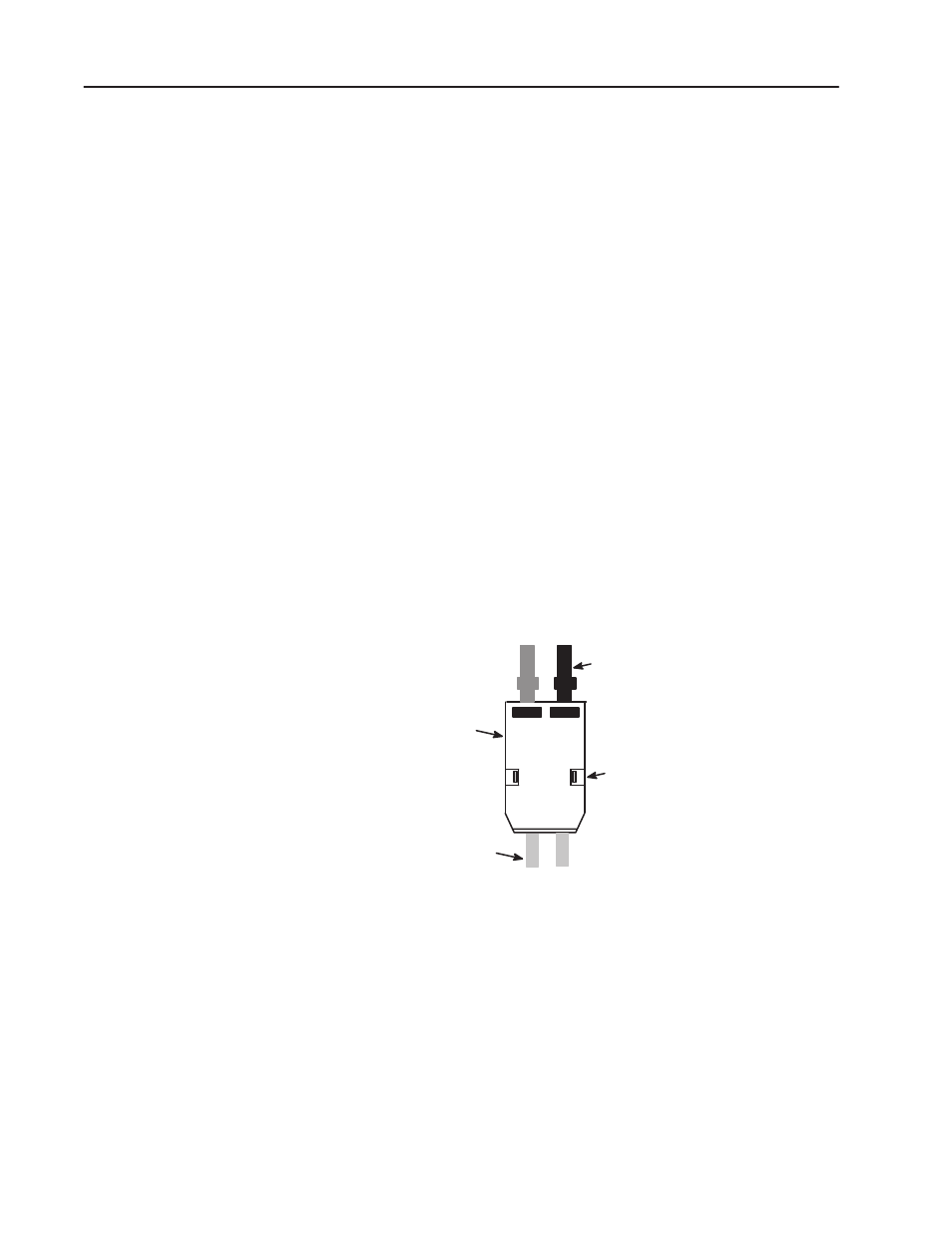

Fiber Optic Connectors

Strain Relief/Cover

Latches

Incoming Fiber Optic Cables

Figure 4.4. Strain Relief Components

To remove the strain relief/latching cover squeeze the two latches

inward and lift the upper half off from the cable end (bottom) of the

cover assembly.