Care and use manual, C. initial column efficiency determination, Ii. column use – Waters SunFire Columns User Manual

Page 3: A. guard columns, B. sample preparation

[ Care and Use ManUal ]

3

2. Purge the column with the mobile phase until you obtain a stable

baseline.

3. Verify that retention times and peak areas for a standard are

stable by comparing 2-3 replicate, consecutive injections.

Before you perform the first analysis on your new column, perform an

efficiency test to confirm the performance of the column.

c. Initial Column efficiency determination

1. Perform an efficiency test on the column before using it. Waters

recommends using a suitable solute mixture, as found in the

“Performance Test Chromatogram”, to analyze the column upon

receipt. However, if the column is used only for a single routine

isocratic assay, it may be more convenient to test the column

under these assay conditions. Keep a record of the initial column

performance.

2. Determine the number of theoretical plates (N) and use this value

for periodic comparisons.

3. Repeat the test at predetermined intervals to track column

performance over time. Slight variations may be obtained on

two different HPLC systems due to the quality of the connections,

operating environment, system electronics, reagent quality,

column condition and operator technique.

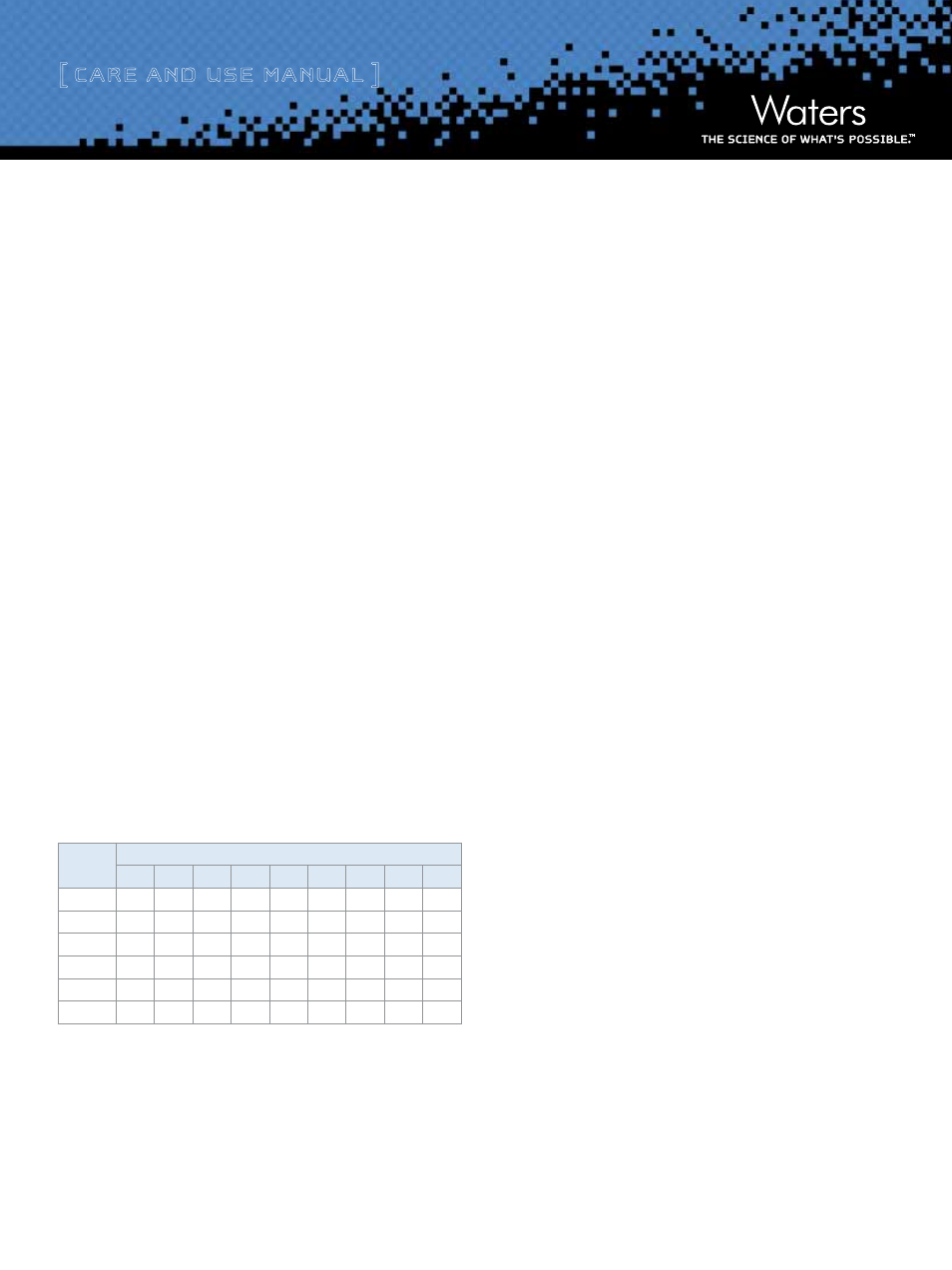

table 1. empty Column Volumes in ml (multiply by 10 for flush

solvent volumes)

Column

Length

Column Internal Diameter (nm)

1.0

2.1

3.0

4.6

7.8

10

19

30

50

20 mm

-

0.07 0.14 0.33

-

-

-

-

-

30 mm

-

0.1

0.2

0.5

-

2.4

8

-

-

50 mm

0.1

0.2

0.3

0.8

2.4

4

14

35

98

100 mm

0.1

0.4

0.7

1.7

5

8

28

70

196

150 mm

0.1

0.5

1.0

2.5

7

12

42

106

294

250 mm

-

0.9

1.8

4

-

20

70

176

490

II. Column uSe

To ensure the continued high performance of SunFire columns, follow

these guidelines:

a. Guard Columns

Use a SunFire guard column of matching chemistry and particle size

between the injector and main column. It is important to use a matching

guard column to protect the main column while not compromising or

changing the analytical resolution. Guard columns need to be replaced

at regular intervals as determined by sample contamination. When

system backpressure steadily increases above a set pressure limit, it

is usually an indication that the guard column should be replaced. A

sudden appearance of split peaks or other changes in chromatographic

performance is also indicative of a need to replace the guard column.

b. Sample Preparation

1. Sample impurities often contribute to column contamination.

One option to avoid this is to use Oasis

®

solid-phase extraction

cartridges/columns or Sep-Pak

®

cartridges of the appropriate

chemistry to clean up the sample before analysis. Link to

www.waters.com/sampleprep

2. It is preferable to prepare the sample in the operating mobile

phase or a mobile phase that is weaker (less organic modifier

in the case of reversed-phase chromatography, less polar

modifier in the case of normal-phase chromatography or

hydrophilic interaction chromatography, less salt in the case

of ion exchange) than the mobile phase for the best peak shape

and sensitivity.

3. If the sample is not dissolved in the mobile phase, ensure that the

sample, solvent and mobile phases are miscible in order to avoid

sample and/or buffer precipitation. Filter sample with 0.2 μm

membranes to remove particulates. If the sample is dissolved in a

solvent that contains an organic modifier (e.g., acetonitrile,

methanol, etc.) ensure that the membrane material does not

dissolve in the solvent. Contact the membrane manufacturer with

solvent compatibility questions. Alternatively, centrifugation for

20 minutes at 8,000 rpm, followed by the transfer of the

supernatant liquid to an appropriate vial, could be considered.