Care and use manual – Waters Spherisorb Columns User Manual

Page 2

[ Care and Use ManUal ]

Waters Spherisorb Columns

2

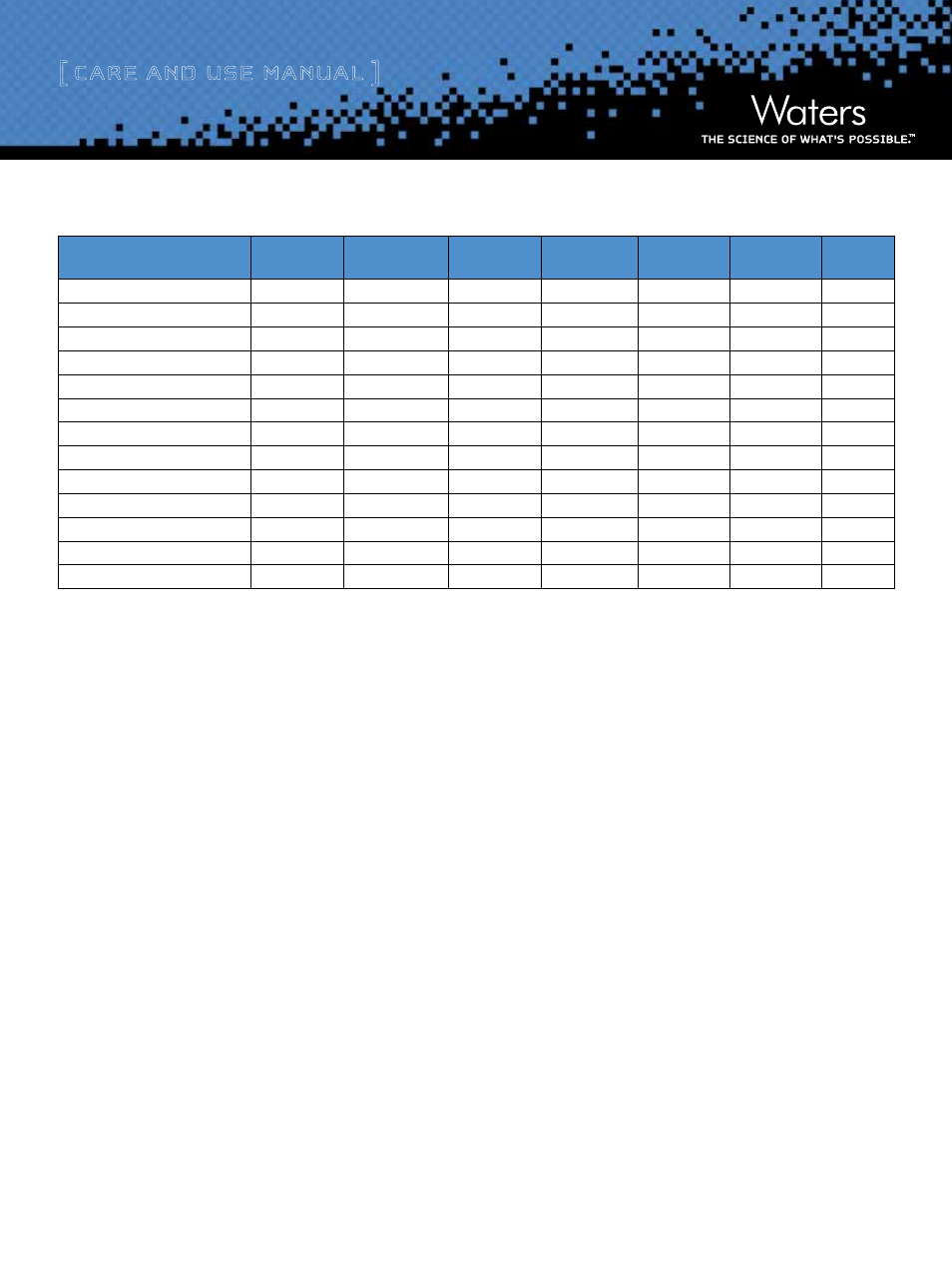

Chemistry

Particle

Shape

Particle Size

(µm)

Pore Size

(Å)

Surface Area

(m

2

/g)

Pore Volume

(cc/g)

% Carbon

Load

Endcapped

Silica

Spherical

3, 5 and 10

80

220

0.50

n/a

n/a

ODS2 (C

18

) - Fully End Capped

Spherical

3, 5 and 10

80

220

0.50

11.5

yes

ODS1 (C

18

) - Partially End Capped

Spherical

3, 5 and 10

80

220

0.50

6.2

no

ODSB (C

18

) - Base De-activated

Spherical

5

80

220

0.50

11.5

yes*

C

8

Spherical

3, 5 and 10

80

220

0.50

5.8

yes

C

6

Spherical

3, 5 and 10

80

220

0.50

4.7

yes

C

1

Spherical

3, 5 and 10

80

220

0.50

2.2

no

Nitrile (CN)

Spherical

3, 5 and 10

80

220

0.50

3.1

no

Amino (NH

2

)

Spherical

3, 5 and 10

80

220

0.50

1.9

no

Phenyl

Spherical

3, 5 and 10

80

220

0.50

2.5

no

OD/CN (Mixed Mode)

Spherical

5

80

220

0.50

5.0

yes

SAX

Spherical

3, 5 and 10

80

220

0.50

4.0

no

SCX

Spherical

3, 5 and 10

80

220

0.50

4.0

no

i. Get tinG started

Each Spherisorb column comes with a Performance Test

Chromatogram. This Performance Test Chromatogram is specific

to each individual column and contains the following information:

gel batch number, column serial number, USP plate count, USP

tailing factor, capacity factor, and chromatographic conditions.

The performance test chromatogram should be stored for future

reference.

a. Column Installation

Note: The flow rates given in the procedure below are for a typical

4.6 mm i.d. column. Scale the flow rate up or down accordingly based

upon the column i.d., length, particle size, and backpressure of the

Spherisorb column being installed. See “Scaling Up/Down Isocratic

Separations” for calculating flow rates when changing column i.d.

and/or length. See “Connecting the Column to the HPLC” for a more

detailed discussion on HPLC connections.

1. Reversed-Phase Columns

1. Purge the pumping system of any buffer-containing mobile phases and

connect the inlet end of the column to the injector outlet.

2. Flush column with 100% organic mobile phase (methanol or

acetonitrile) by setting the pump flow rate to 0.1 mL/min and increase

the flow rate to 1 mL/min over 5 minutes.

3. When the mobile phase is flowing freely from the column outlet, stop

the flow and attach the column outlet to the detector. This prevents

entry of air into the detection system and gives more rapid baseline

equilibration.

4. Gradually increase the flow rate as described in step 2.

5. Once a steady backpressure and baseline have been achieved, proceed

to the next section.

2. Normal-Phase Columns

Note: It is assumed that your system has been used for reversed-phase

chromatography. If this is not the case, you can start with step 3.

1. Purge the pumping system of any buffer containing mobile phases.

2. Flush the system thoroughly with acetonitrile.

3. Switch the system over to the mobile phase that you are planning to use

in normal-phase chromatography.

4. Connect the column and equilibrate it with the mobile phase.

Note: Equilibration with the mobile phase may require a larger amount of

solvent than in reversed-phase chromatography.

Table 1. Spherisorb Column Physical Characteristics

* polar endcapping