Care and use manual, 36 μl – Waters Symmetry Columns User Manual

Page 8

[ Care and Use ManUal ]

Symmetry Columns

8

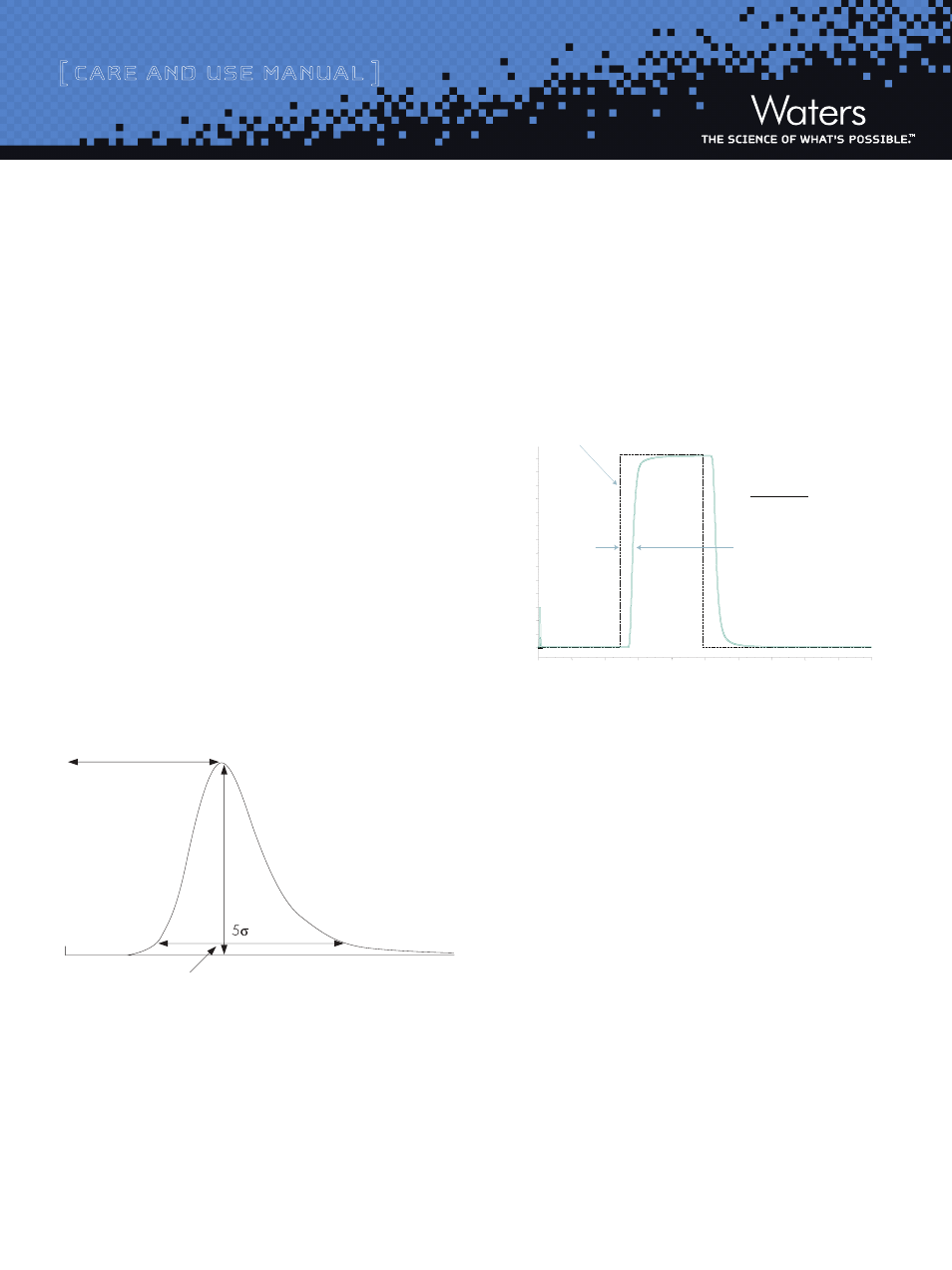

d. Measuring System Bandspreading Volume and System

Variance

This test should be performed on an HPLC system with a single

wavelength UV detector (not a Photodiode Array [PDA]).

1. Disconnect column from system and replace with a zero dead

volume union.

2. Set flow rate to 1 mL/min.

3. Dilute a test mix in mobile phase to give a detector

sensitivity of 0.5 - 1.0 AUFS (system start up test mix can be

used which contains uracil, ethyl and propyl parabens; Waters

P/N WAT034544).

4. Inject 2 to 5 μL of this solution.

5. Measure the peak width at 4.4% of peak height

(5-sigma method):

5-sigma Bandspreading (μL) = Peak Width (min) Flow Rate (mL/min x (1000 μL/1 mL)

System Variance (μL

2

) = (5-sigma bandspreading)

2

/ 25

Figure 8: Determination of System Bandspreading Volume Using

5-Sigma Method

In a typical HPLC system, the Bandspreading Volume should be

100 μL ± 30 μL (or Variance of 400 μL

2

+/- 36 μL

2

).

In a microbore (2.1 mm i.d.) system, the Bandspreading Volume

should be no greater than 20 to 40 μL (or Variance no greater than

16 μL

2

to 64 μL

2

).

e. Measuring System Volume

System volume is important in scaling separations because it

creates an isocratic hold at the start of every run. This hold is often

several column volumes on a small scale, but a fraction of the

volume of a prep column. Compensation for this volume must be

included in planning a scaling experiment to avoid distorting the

chromatography (Figure 9).

Figure 9: Determination of Gradient Delay Volume

1. Remove column.

2. Use Acetonitrile as mobile phase A, and Acetonitrile with 0.05

mg/mL uracil as mobile phase B (eliminates non-additive mixing

and viscosity problems).

3. Set UV detector at 254 nm.

4. Use the flow rate in the original method and the intended flow

rate on the target instrument.

5. Collect 100% A baseline for 5 minutes.

6. Program a step change at 5 minutes to 100% B, and collect data

for an additional 5 minutes.

7. Measure absorbance difference between 100% A and 100% B.

8. Measure time at 50% of that absorbance difference.

9. Calculate time difference between start of step and 50% point.

10. Multiply time difference by flow rate.

5.69 minutes

- 5.00 minutes

0.69 minutes

50%

Time = 5.69 minutes

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0.65

0.70

0

2

4

6

8

10

12

14

16

18

20 min

Programmed time = 5.00 minutes

System Volume:

0.69 min x 1.5 mL/min = 1.04 mL

Flow Rate = 1.5 mL/min

AU

System Volume

4.4% h