Care and use manual – Waters Symmetry Columns User Manual

Page 5

[ Care and Use ManUal ]

Symmetry Columns

5

Guard columns need to be replaced at regular intervals, as

determined by sample contamination. When system backpressure

steadily increases above a set pressure limit, it is usually an

indication that the guard column should be replaced. A sudden

appearance of split peaks is also indicative of a need to replace the

guard column.

b. Storage

For periods longer than four days at room temperature, store the

column in 100% acetonitrile. For elevated temperature applications,

store immediately after use in 100% acetonitrile for the best column

lifetime. Do not store columns in buffered eluents. If the mobile

phase contained a buffer salt, flush the column with 10 column

volumes of HPLC grade water (see Table 1 for common column

volumes) and replace with 100% acetonitrile for storage. Failure to

perform this intermediate step could result in precipitation of the

buffer salt in the column when 100% acetonitrile is introduced.

Completely seal column to avoid evaporation and drying out of the

bed.

Note: If a column has been run with a mobile phase that contains

formate (e.g., ammonium formate, formic acid, etc.) and is then

flushed with 100% acetonitrile, slightly longer equilibration times

may be necessary when the column is re-installed and run again with

a formate-containing mobile phase.

Vii. connectinG the column to the hplc

a. Column Connectors and System Tubing Considerations

Tools needed:

3/8 inch wrench

5/16 inch wrench

Handle the column with care. Do not drop or hit the column on a hard

surface as it may disturb the bed and affect its performance.

1. Correct connection of 1/16 inch outer diameter stainless

steel tubing leading to and from the column is essential for

high quality chromatographic results.

2. When using standard stainless steel compression screw fittings,

it is important to ensure proper fit of the 1/16 inch outer

diameter stainless steel tubing. When tightening or loosening

the compression screw, place a 5/16 inch wrench on the

compression screw and a 3/8 inch wrench on the hex head of the

column endfitting.

Note: If one of the wrenches is placed on the column tube flat during

this process, the endfitting will be loosened and leak.

3. If a leak occurs between the stainless steel compression screw

fitting and the column endfitting, a new compression screw

fitting, tubing and ferrule must be assembled.

4. An arrow on the column identification label indicates correct

direction of solvent flow.

Correct connection of 1/16 inch outer diameter stainless steel

tubing leading to and from the column is essential for high-quality

chromatographic results. Tubing touches the bottom of the column

endfitting, with no void between them. It is important to realize that

extra column peak broadening can destroy a successful separation.

The choice of appropriate column connectors and system tubing is

discussed in detail below.

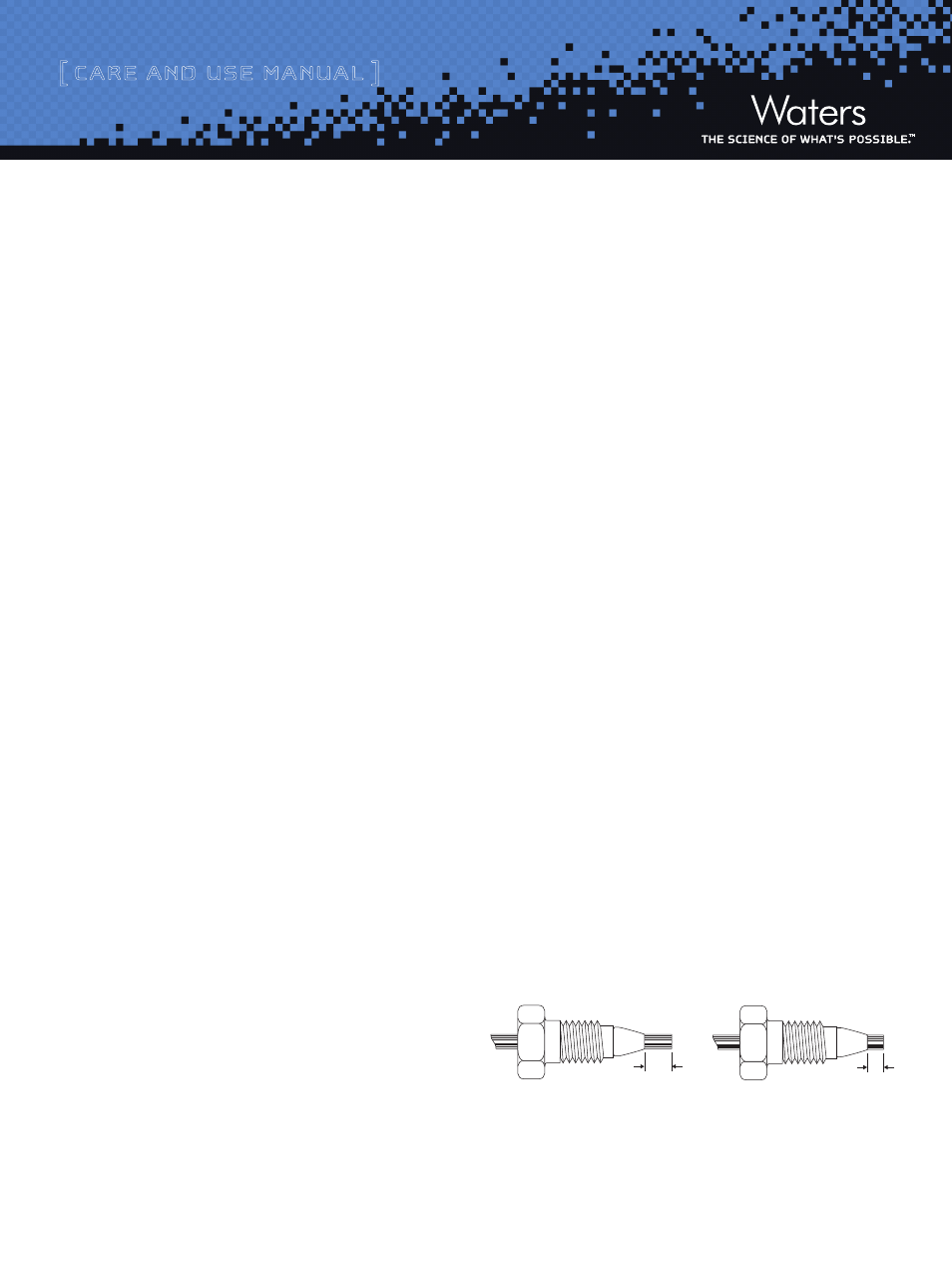

Due to the absence of an industry standard, various column

manufacturers have employed different types of chromatographic

column connectors. The chromatographic performance of the

separation can be negatively affected if the style of the column

endfittings does not match the existing tubing ferrule settings. This

section explains the differences between Waters style and Parker

style ferrules and endfittings (Figure 1). Each endfitting style varies

in the required length of the tubing protruding from the ferrule.

The Symmetry column is equipped with Waters style endfittings

that require a 0.130 inch ferrule. If a non-Waters style column is

presently being used, it is critical that ferrule depth be reset for

optimal performance prior to installing a Symmetry column.

Figure 1: Waters and Parker Style Ferrule Types

0.130 inches

0.0 0 inches

Parker Style Ferrule Settings

Waters Ferrule Settings