Care and use manual, Iv. scaling up/down isocratic methods, V. troubleshooting – Waters Symmetry Columns User Manual

Page 4: Vi. column cleaning, regenerating and storage

[ Care and Use ManUal ]

Symmetry Columns

4

d. Solvents

To maintain maximum column performance, use high quality

chromatography grade solvents. Filter all aqueous buffers prior to

use. Pall Gelman Laboratory Acrodisc

®

filters are recommended.

Solvents containing suspended particulate materials will generally

clog the outside surface of the inlet distribution frit of the column.

This will result in higher operating pressure and poorer performance.

Degas all solvents thoroughly before use to prevent bubble formation

in the pump and detector. The use of an on-line degassing unit is

also recommended. This is especially important when running low

pressure gradients since bubble formation can occur as a result of

aqueous and organic solvent mixing during the gradient.

e. Pressure

Symmetry columns can tolerate pressures of up to 6,000 psi

(400 bar or 40 Mpa) although pressures greater than

4,000 – 5,000 psi should be avoided in order to maximize

column and system lifetimes.

f. Temperature

Temperatures between 20 ˚C – 45 ˚C are recommended for operating

Symmetry columns in order to enhance selectivity, lower solvent

viscosity and increase mass transfer rates. However, any temperature

above ambient will have a negative effect on lifetime which will vary

depending on the pH and buffer conditions used.

iV. scalinG up/down isocratic methods

The following formulas will allow scale up or scale down, while

maintaining the same linear velocity, and provide new sample

loading values:

If column i.d. and length are altered:

F

2

= F

1

(r

2

/r

1

)

2

or

Injection volume

1

= Injection volume

2

(r

2

/r

1

)

2

(L

2

/L

1

)

Where: r = Radius of the column, in mm

F = Flow rate, in mL/min

L = Length of column, in mm

1 = Original, or reference column

2 = New column

V. troubleshootinG

Changes in retention time, resolution, or backpressure are often due

to column contamination. See “Column Cleaning, Regenerating and

Storage.” Information on column troubleshooting problems may be

found in the current Waters Chromatography Columns and Supplies

Catalog. You can also download a copy of the HPLC Troubleshooting

Guide at www.waters.com, click on “Literature Library”, then in the

Information Center Search Box, enter WA20769.

Vi. column cleaninG, reGeneratinG and storaGe

a. Cleaning and Regenerating

Changes in peak shape, peak splitting, shoulders on the peak, shifts

in retention, change in resolution or increasing backpressure may

indicate contamination of the column. Flushing with a neat organic

solvent, taking care not to precipitate buffers, is usually sufficient

to remove the contaminant. If the flushing procedure does not solve

the problem, purge the column using the following cleaning and

regeneration procedures. Use the cleaning routine that matches

the properties of the samples and/or what you believe is

contaminating the column (see Table 3). Flush columns with 20

column volumes of HPLC-grade solvents (e.g., 80 mL total for

4.6 x 250 mm column). Increasing mobile phase temperature to

35-55 ˚C increases cleaning efficiency. If the column performance is

poor after regenerating and cleaning, call your local Waters office for

additional support.

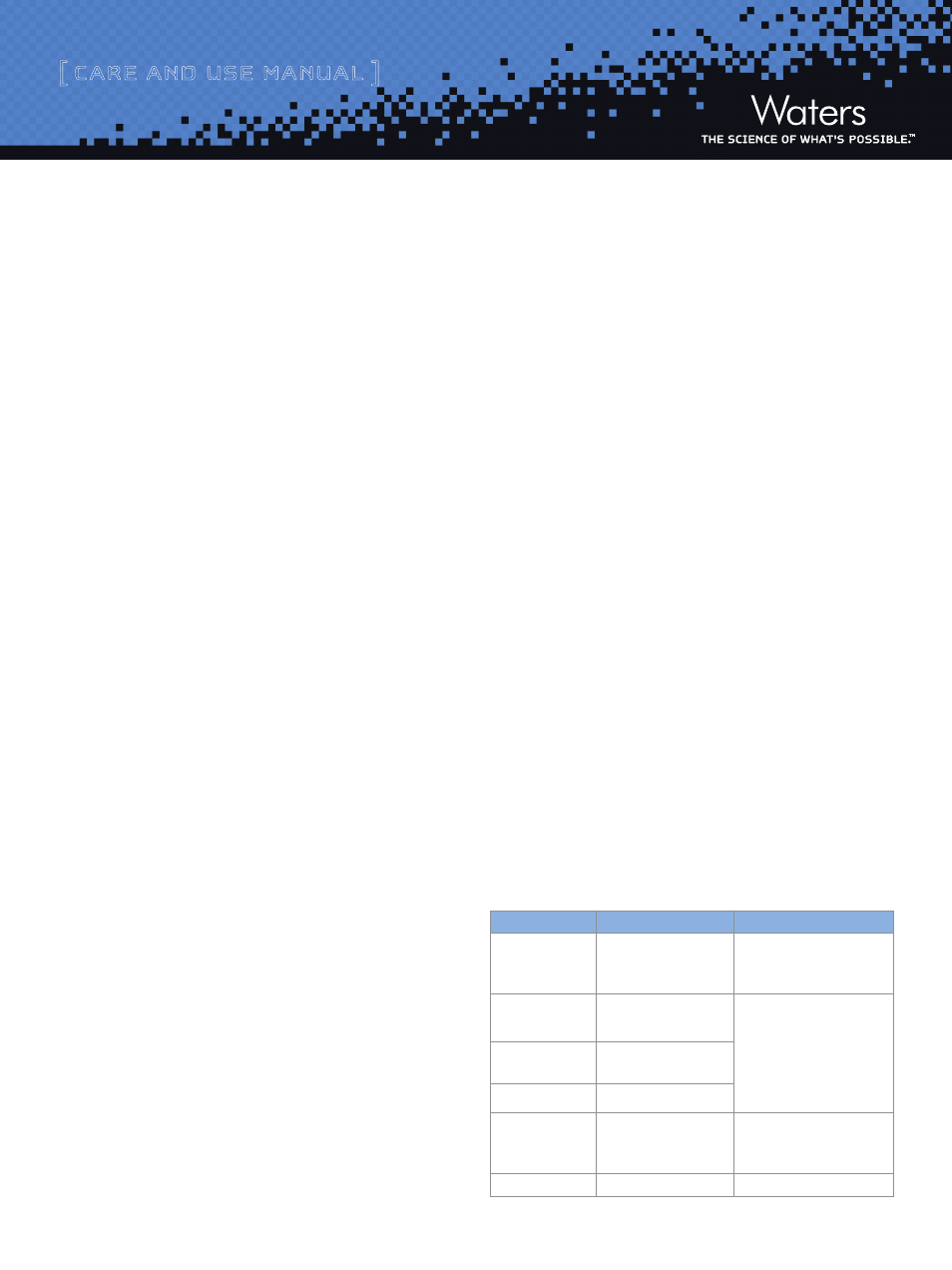

Table 3: Column Sequence or Options

* Use low organic solvent content to avoid precipitating buffers.

Polar Samples

Non-polar Samples

Proteinaceous Samples

1. Water

1. Isopropanol (or an

appropriate isopropanol/

water mixture*)

Option 1: Inject repeated

aliquots of dimethyl

sulfoxide (DMSO)

2. Methanol

2. Tetrahydrofuran (THF) Option 2: gradient of

10% to 90% B where:

A = 0.1% trifluoroacetic acid

(TFA) in water

B = 0.1% trifluoroacetic acid

(TFA) in acetonitrile (CH

3

CN)

3. Tetrahydrofuran

(THF)

3. Dichloromethane

4. Methanol

4. Hexane

5. Water

5. Isopropanol (followed

by an appropriate isopro-

panol/water mixture*)

Option 3: Flush column with

7M guanidine hydrochloride,

or 7M urea

6. Mobile Phase

6. Mobile Phase