Seed meter (finger pickup) troubleshooting, Seed meter (finger pickup) troubleshooting -8 – Kinze 3200 Wing-Fold Planter Rev. 7/14 User Manual

Page 188

M0241-01

Model 3200

8-8

6/11

TM

Troubleshooting

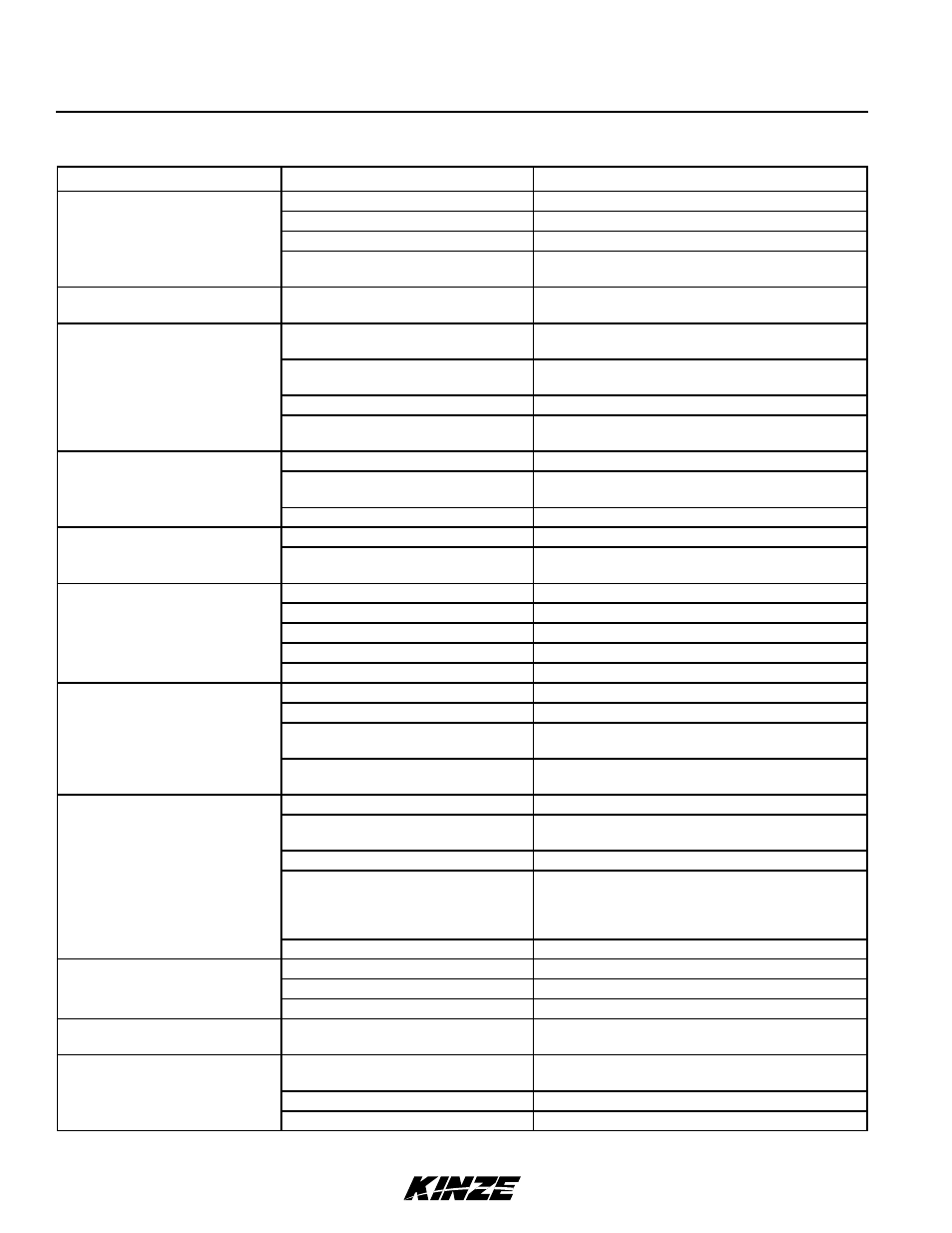

SEED METER (FINGER PICKUP) TROUbLESHOOTING

PRObLEM

POSSIbLE CAUSE

SOLUTION

One row not planting seed.

Drive release not engaged.

Engage drive release mechanism.

Foreign material in hopper.

Clean hopper and finger carrier mechanism.

Seed hopper empty.

Fill seed hopper.

Row unit drive chain off of

sprocket or broken.

Check drive chain.

Drive release does not engage

properly.

Drive release shaft is not aligned

properly with meter drive shaft.

Align drive mechanism.

Unit is skipping.

Foreign material or obstruction

in meter.

Clean and inspect.

Finger holder improperly

adjusted.

Adjust to specifications. (22 to 25 in. lbs. rolling

torque)

Broken fingers.

Replace fingers and/or springs as required.

Planting too slowly.

Increase planting speed to within

recommended range.

Planting too many doubles.

Planting too fast.

Stay within recommended speed range.

Loose finger holder.

Adjust to specifications. (22 to 25 in. lbs.

rolling torque)

Worn brush in carrier plate.

Inspect and replace if necessary.

Overplanting.

Worn carrier plate.

Inspect and replace if necessary.

Seed hopper additive being used.

Reduce or eliminate additive or increase

graphite.

Underplanting.

Seed belt installed backwards.

Remove and install correctly.

Weak or broken springs.

Replace.

Spring not properly installed.

Remove finger holder and correct.

Seed belt catching or dragging.

Replace belt.

Brush dislodging seed.

Replace brush.

Irregular or incorrect seed

spacing.

Driving too fast.

Check chart for correct speed.

Wrong tire pressure.

Inflate tires to correct air pressure.

Drive wheels slipping.

Reduce down pressure on row unit down

force springs.

Wrong sprockets.

Check seed rate charts for correct sprocket

combinations.

Seed spacing not as indicated

in charts.

Wrong tire pressure.

Inflate tires to correct air pressure.

Inconsistent seed size.

Perform field check and adjust sprockets

accordingly.

Wrong sprockets.

Check chart for correct sprocket combination.

Charts are approximate.

Slight variations due to wear in meter

components and tire slippage due to field

conditions may produce seed spacing

variations.

Stiff or worn drive chains.

Replace chains.

Scattering of seeds.

Planting too fast.

Reduce planting speed.

Seed tube improperly installed.

Check seed tube installation.

Seed tube worn or damaged.

Replace seed tube.

Seed tubes and/or openers

plugging.

Allowing planter to roll backward

when lowering.

Lower planter only when tractor is moving

forward.

Inconsistent seed depth.

Rough seed bed.

Adjust down pressure springs.

Reduce planting speed.

Partially plugged seed tube.

Inspect and clean.

Seed tube improperly installed.

Install properly.