Wheel bearing repack or replacement, Edgevac check valve inspection, Edgevac relief valve cartridge inspection – Kinze 3200 Wing-Fold Planter Rev. 7/14 User Manual

Page 166: Wheel bearing repack or replacement -26, Edgevac check valve inspection -26, Edgevac relief valve cartridge inspection -26

M0241-01

Model 3200

7-26

6/11

TM

Lubrication and Maintenance

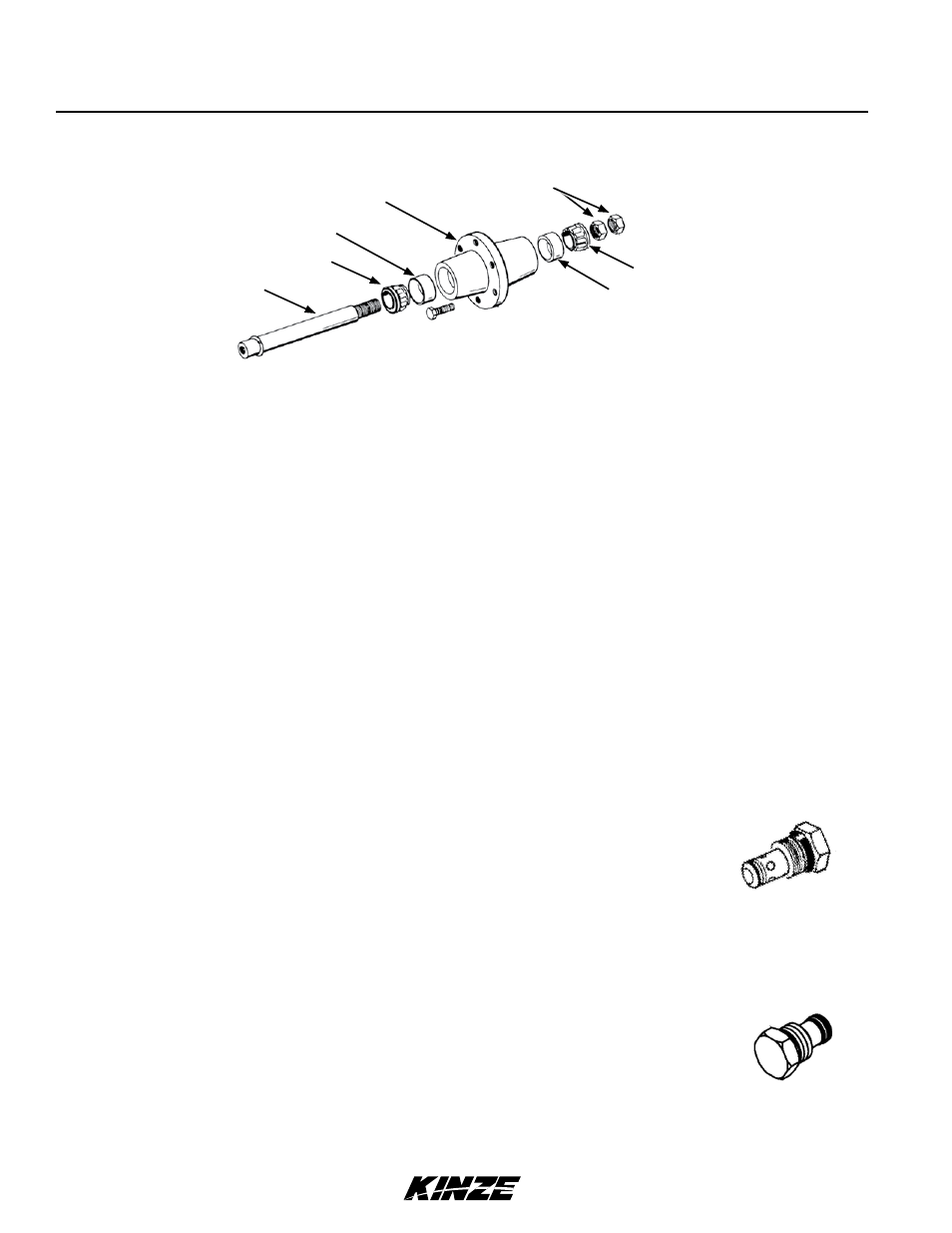

1. Raise tire clear of ground and remove wheel.

2. Remove double jam nuts and slide hub from spindle.

3. Remove bearings and cups and discard if bearings are being replaced. Clean hub and dry. Remove bearings

only and not cups if repacking.

4. Press in new bearing cups with thickest edge facing in. (Bearing replacement procedure only.)

5. Pack bearings with heavy duty wheel bearing grease thoroughly forcing grease between roller cone and bearing

cage. Fill space between bearing cups and hub with grease.

6. Place inner bearing in place.

7. Clean spindle and install hub.

8. Install outer bearing and jam nut. Tighten jam nut while rotating hub until there is some drag. This ensures all

bearing surfaces are in contact. Back off jam nut ¼ turn or until there is only slight drag when rotating hub. Install

second jam nut to lock against first.

9. Install wheel on hub. Tighten hardware evenly.

WHEEL bEARING REPACK OR REPLACEMENT

Spindle

Inner bearing

Hub

Bearing cup

Bearing cup

Outer bearing

Jam nuts

EDGEVAC CHECK VALVE INSPECTION

(In valve block below vacuum fan motor assembly)

Check valve return prevents reverse operation of vacuum fan motor. Remove and check for

foreign material or if O-ring is leaking internally. Clean or replace if defective.

EDGEVAC RELIEF VALVE CARTRIDGE INSPECTION

(In valve block below vacuum fan motor assembly)

NOTICE

Connect hydraulic motor case drain to a case drain return line with zero pressure on

tractor or hydraulic motor will be damaged. DO NOT connect hydraulic motor case drain

to SCV outlet. Contact tractor manufacturer for specific details on “zero pressure return”.

Pressure relief valve helps prevent damage to vacuum fan motor by limiting pressure in motor

case drain line. It is set to open at 35 PSI (241.21 kPa). Remove and check for foreign material

and contamination on valve or seating area of valve body. Clean or replace if defective.