Control parameters – JULABO Magnum 91 Temperature System User Manual

Page 43

Temperature System Magnum 91

43

8.2. Control

parameters

Configuration

>Control param.

Profile Start

Int.Programmer

Inputs/Outputs

Limits

Interface

Temp.Sensor

Control param.

>Xp = 2.5 K

Tn = 220 s

Tv = 1 S

Xp =

When performing an identification for the controlled system (temperature

applications system) (see page 40), the control parameters Xp, Tn, Tv and

Xpu will be automatically determined and stored.

Each parameter may be manually set via the keypad if necessary, to allow

optimum control performance.

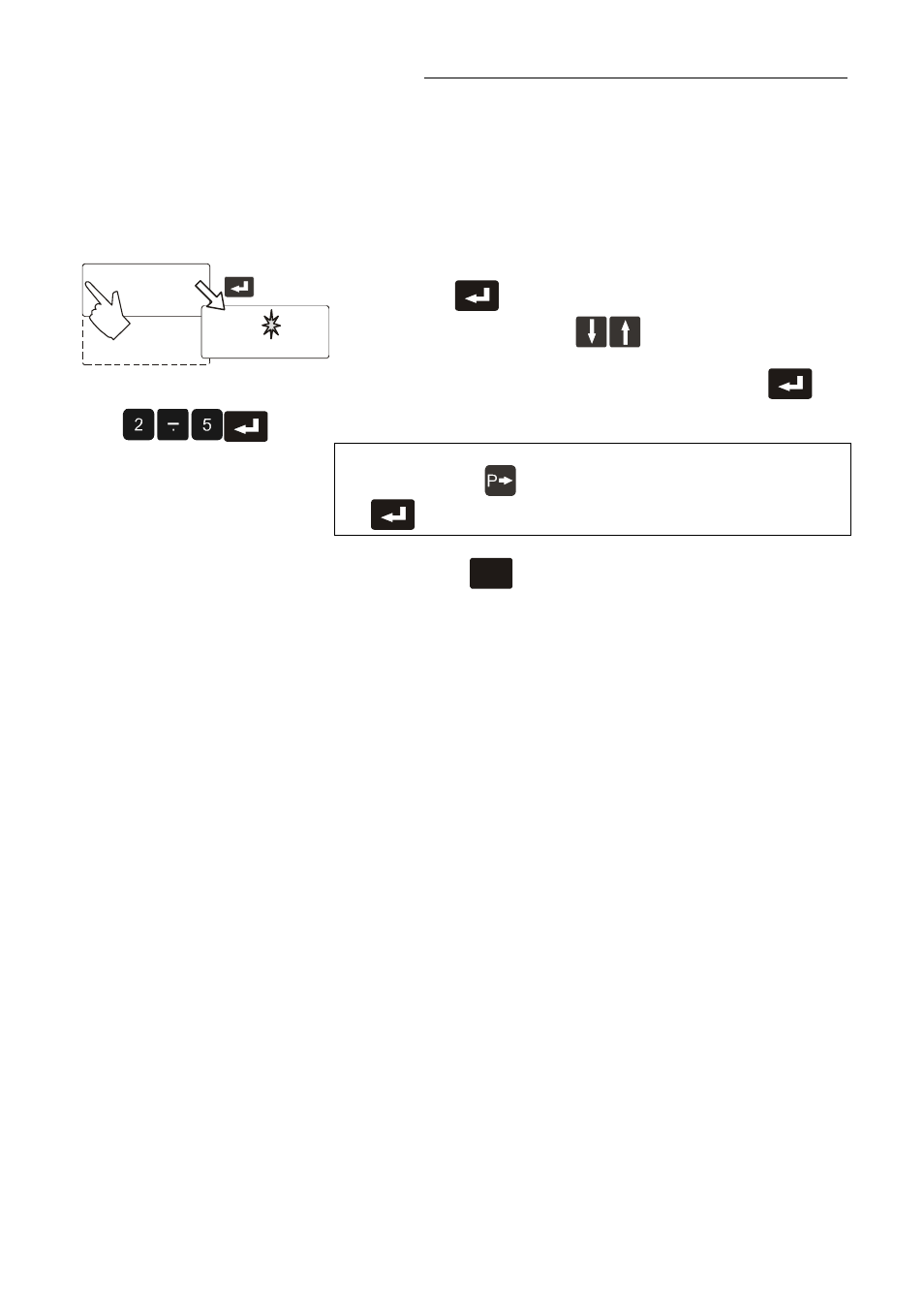

Press

enter

to select the submenu "control parameters".

Use the up/down cursor keys

to select the desired option. A

flashing segment indicates that a new value needs to be entered.

Use the numerals to set the value and then set with enter

(example: Xp = 2.5 °C).

or at >DynInt<

Press the P-key

to select the parameter and press enter

.

Press

escape

ESC

to return to the previous menu level.

Proportional range >Xp<

The proportional range is the range below the selected temperature value

in wich the the control circuit reduces the heating power from 100 % to 0

%.

Resetting time >Tn< (Integral component)

Compensation of the remaining control deviation due to proportional

regulation. An insufficient resetting time may cause instabilities to occur.

Excessive resetting time will unnecessarily prolong compensation of the

control difference.

Lead time >Tv< (Differential component)

The differential component reduces the control settling time. An

insufficient lead time will prolong the time required to compensate for

disturbance effects and cause high overshooting during run-up. An

excessive lead time could cause instabilities (oscillations) to occur.

Proportional range >Xpu<

The proportional range Xpu of the cascaded controller is only needed for

external control.