3 setup and function, 1 hardware setup, 2 control elements/connections – HYDAC CMU 1000 User Manual

Page 13

Condition Monitoring Unit CMU 1000

Page 13

Revised 17.12.2009

HYDAC ELECTRONIC GMBH Mat.-No.:

669749

3 Setup and Function

The CMU1000 is an electronic device for regular (permanent) status monitoring of

hydraulic systems or machinery.

This procedure is also referred to as "Condition Monitoring".

3.1 Hardware Setup

In order to fulfill the aforementioned task, the CMU 1000 must be supplied with relevant

machinery and/or systems data, which it receives through connected sensors. The

recorded data (whether processed or unprocessed) can be forwarded by the CMU

1000 through various interfaces to other units.

The CMU 1000 is equipped with a background-lit LCD display as well as three

different-colored LEDs for the status display and presentation of messages and values.

The entering of data and commands can proceed directly at the device by means of a

keypad,

within the specified menu structure, among other ways.

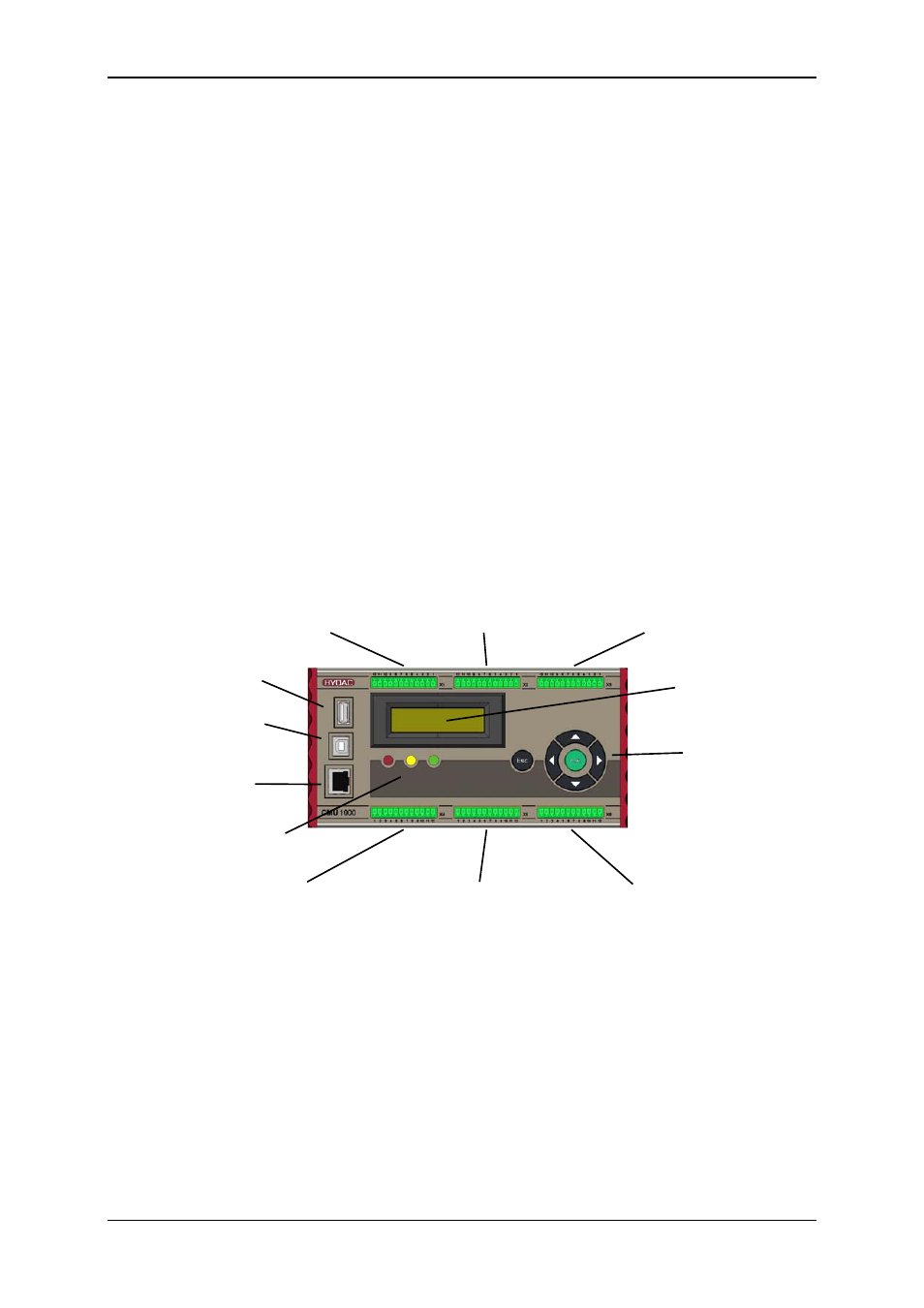

3.2 Control Elements/Connections

X1

X2

X3

HSI-channel A, B, C

HSI-channel D, E, F

HSI-channel G, H

Analog IN I, J, K

Analog IN L, M, N

Analog IN O, P and ± 10V L, P

with power supply

with power supply

with power supply

USB Master

(for MSD)

LCD display

USB Slave

(PC connection)

Keypad

Ethernet

Status LEDs

X4

X5

X6

CAN, Frequency IN Q, R, Power supply. 24V 4x Relay OUT

Digital IN, Analog OUT RS232, HSI-Master, (changer)

IO-Link