Enerpac ATP-Series User Manual

Page 8

8

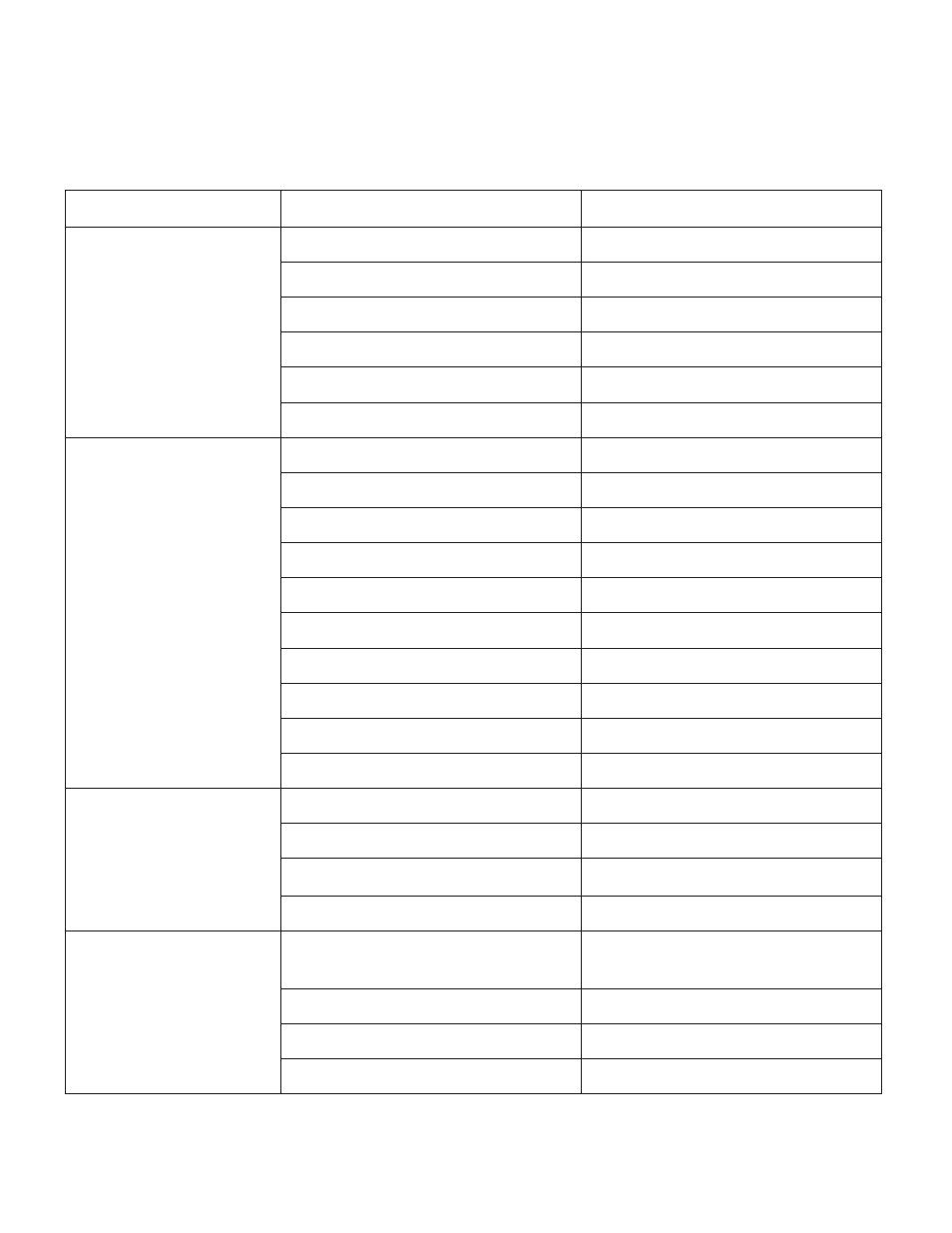

8.0 TROUBLESHOOTING

Only qualifi ed hydraulic technicians should service the pump or system components. A system failure is not necessarily the result of

a pump malfunction. To determine the cause of the problem, the complete system must be considered in any diagnostic

procedure.

The following troubleshooting chart is intended to be used only as an aid in determining if a problem exists. For repair service, contact

your Enerpac Authorized Service Center.

Problem

Possible Cause

Action

Pump does not cycle.

No air pressure at supply.

Check air supply.

Pump air-shutoff valve closed.

Open pump air-shutoff valve.

Pump air pressure regulator set too low.

Check pressure regulator setting.

Pump air fi lter dirty.

Replace air fi lter element.

Pump air motor worn or damaged.

Contact Enerpac Authorized Service Center.

Pump element jammed.

Contact Enerpac Authorized Service Center.

Pump fails to build hydraulic

pressure or builds less than desired

pressure.

Low air pressure or volume at air supply.

Check air supply.

Pump air pressure regulator set too low.

Check regulator setting.

Pump air fi lter dirty.

Replace air fi lter element.

Pump return-to-tank valve open or not fully closed.

Close return-to-tank valve.

Low oil level in reservoir.

Check oil level. Add oil as required.

Pump hydraulic fi lter dirty.

Clean or replace hydraulic fi lter element.

Oil leakage at hydraulic hoses, fi ttings or tools.

Replace leaking items as required.

Pump return-to-tank valve leaking.

Replace return-to-tank valve.

Pump air motor worn or damaged.

Contact Enerpac Authorized Service Center.

Internal leakage in pump element and/or air motor.

Contact Enerpac Authorized Service Center.

Jerky or erratic pump operation.

Low air pressure or volume at air supply.

Check air supply.

Pump not primed and/or air in hydraulic lines.

Prime the pump as described in Section 4.4.

Hydraulic oil dirty.

Change hydraulic oil. Use only Enerpac HF oil.

Clean or replace hydraulic fi lter element.

Pump element worn or damaged.

Contact Enerpac Authorized Service Center.

Excessive moisture in pump exhaust.

Excessive water and/or lubricant in supply air.

Reduce moisture in air. Install water separator.

Note: Pump components are self-lubricating.

Lubricated air is not required.

Pump air fi lter bowl needs draining.

Check bowl for water. Drain as required.

Pump air fi lter dirty.

Replace air fi lter element.

Internal leakage in pump element and/or air motor.

Contact Enerpac Authorized Service Center.