Enerpac ATP-Series User Manual

Page 2

2

2.2 ATP-1500 Safety Precautions

Warning: Failure to observe the following precautions may

result in serious personal injury or death!

• Always wear eye protection, gloves and boots when operating

the pump.

• High pressure hydraulic equipment can be very dangerous if

misused. Keep away from oil leakages at high pressure. Liquid

escaping from highly pressurized equipment has suffi cient

power to penetrate the skin, which can cause blood poisoning.

In the case of such an accident, seek IMMEDIATE medical

attention.

•

Never attempt to disconnect a

hydraulic coupler while it is under

pressure.

•

Never attempt to repair leaks while

the system is pressurized. Be sure

system pressure gauge indicates zero

[0] psi/bar before making any repairs.

•

Never pressurize the back of

a disconnected male

coupler. Serious personal

injury could result if the

coupler fails while under

pressure.

•

Use caution when

pressurizing a system.

Pressure can rise faster than

anticipated. Continuously

monitor the pressure gauge

during pressurization. Be

prepared to stop

pressurization immediately

at any time.

• Before operation, ensure that quick-disconnect couplings are

properly connected by physically pulling on them.

• Allow only trained and experienced personnel to operate the

pump. Be especially careful to avoid accidental pump start-up.

• Never leave the pump pressurized and unattended. If you must

leave the area, close the air-shutoff valve and ensure that the

release (return-to-tank) valve on the pump is fully open. Turn

the air pressure regulator knob counter-clockwise until zero [0]

psi/bar is indicated on the air pressure gauge.

• Never exceed the safe working pressure for the hydraulic

hoses, tools or pump. The maximum allowable operating

pressure (hydraulic) for the ATP-1500 pump is 21,755 psi [1500

bar].

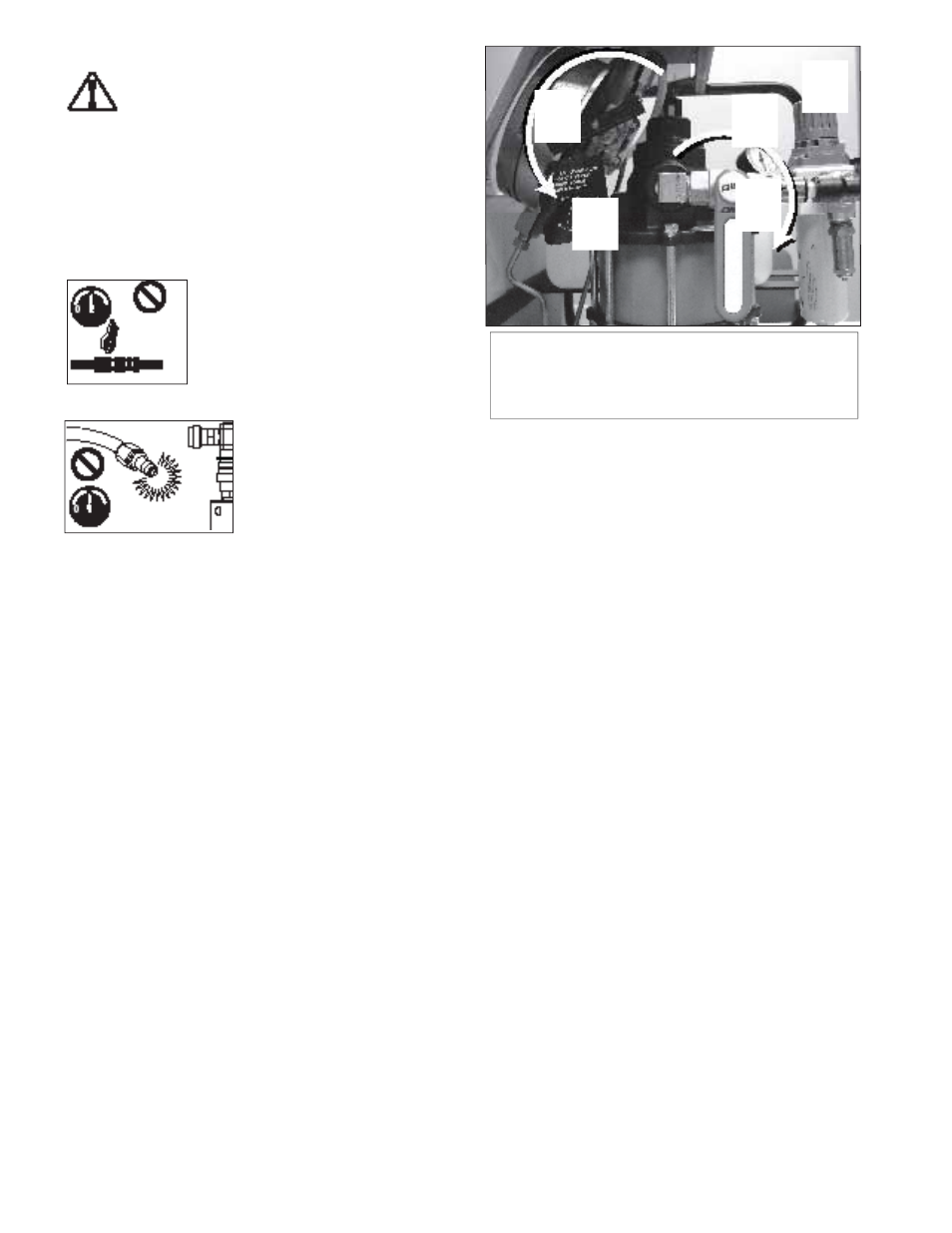

➊

➋

➌

➍

➎

Key:

➊

OPEN

➋

CLOSED

➌

Return-to-Tank Valve

➍

Air Pressure Regulator

➎

Air-Shutoff Valve

Figure 1, Before Connecting Air Supply

• Before connecting air supply: Ensure that the air-shutoff (on-

off) valve is closed (i.e. handle in vertical position) and that the

oil return-to-tank valve is open. See Figure 1.

• Check the air pressure gauge after connecting air supply. If any

pressure is indicated, turn the air pressure regulator knob

counter-clockwise until the gauge indicates zero [0] psi/bar.

• Always pressurize the pump starting at zero [0] psi/bar air

pressure and work upward. Turn air pressure regulator knob

SLOWLY to prevent sudden and unexpected increases in

hydraulic pressure.

• After the desired hydraulic pressure has been obtained, always

close the air-shutoff valve and turn the air pressure regulator

knob counter-clockwise until zero [0] psi/bar is indicated on the

air pressure gauge.

• Always depressurize before leaving the system unattended.